NiTiNol Alloy

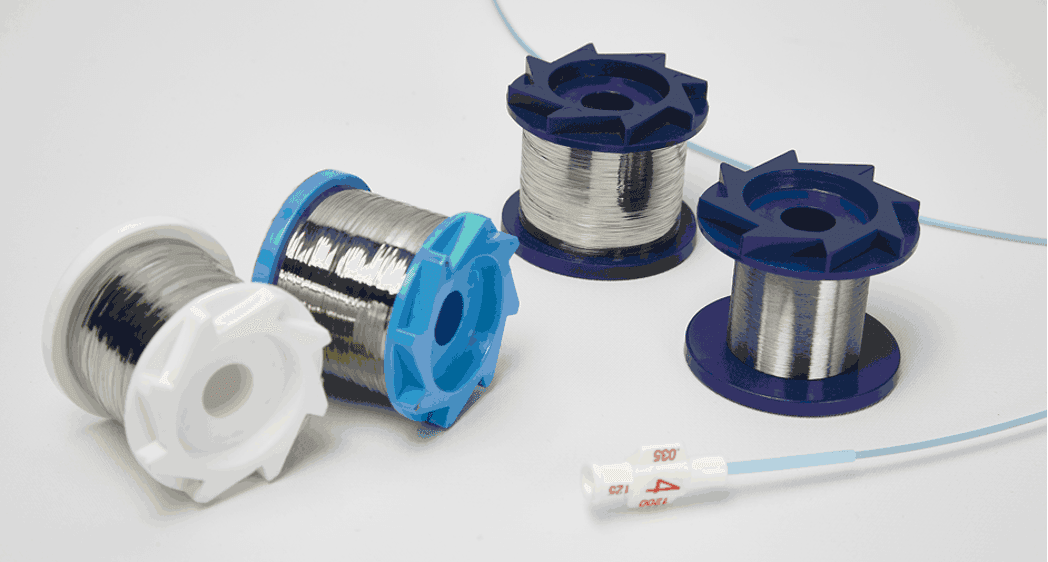

The main products of NiTiNol Alloy (SME and SMA) include wire and rod, sheet foil and plate, springs, spectacle frame/glasses frame, powder, and other machined parts.

MetalsTek Engineering emerges as a pioneering force in NiTiNol, showcasing unparalleled expertise and innovation in producing Nickel Titanium Naval Ordnance Laboratory (NiTiNol) alloys. Our commitment to excellence in NiTiNol manufacturing sets us apart as a trusted partner for industries at the forefront of technological advancements.

MetalsTek Engineering emerges as a pioneering force in NiTiNol, showcasing unparalleled expertise and innovation in producing Nickel Titanium Naval Ordnance Laboratory (NiTiNol) alloys. Our commitment to excellence in NiTiNol manufacturing sets us apart as a trusted partner for industries at the forefront of technological advancements.

NiTiNol Wire Rod

Material: NiTi, NiTiCu, NiTiFe, NiTiCr, NiTiNb, etc.

Size: Diameter ≥0.05 mm

Shape: Straight, Spool, Coil; Round Wire or Flat Wire

Standard: ASTM F2063

Austenite Finish Temperature: -15 ℃ ~ 100 ℃

Applications: Dental Uses, Guide Wire, Glass Frame, Jewelry, Toys, etc.

Nitinol Spring

Material: Titanium Nickel Alloy

Model: Round Wire Spring, Flat Wire Spring

Type: One-Way Shape Memory, Two-Way Shape Memory

Austenite Finish Temperature: One-Way 0 ℃ ~ 100 ℃; Two-Way 15 ℃ ~ 60 ℃

Other: Customized Per Data/Drawing

NiTiNol Foil Sheet Plate

Material: NiTi, NiTiCu, NiTiFe, NiTiCr, NiTiNb, etc.

Size: Thickness ≥0.05 mm, Cold Rolling Surface

Shape: Straight, Spool, Coil

Standard: ASTM F2063

Austenite Finish Temperature: -15 ℃ ~ 100 ℃

Applications: Dental Uses, Guide Wire, Glass Frame, Jewelry, Toys, etc.

NiTiNol Powder

Composition: Nickel, Titanium

Purity: 99.9% Minimal

Properties: Gray, 4.0g/cc Min. Tap Density, Hot Flow Rate ≤30.0 s/50g

Particle Size: 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 5-150μm

Chemical Compositions (%)

| Ni | Ti | Al | Cu | Mo | Si | Fe | Mg |

|---|---|---|---|---|---|---|---|

| 40~50 | 50~60 | <0.1 | <0.03 | <0.01 | <0.01 | <0.05 | <0.02 |

Applications of NiTiNol Powder

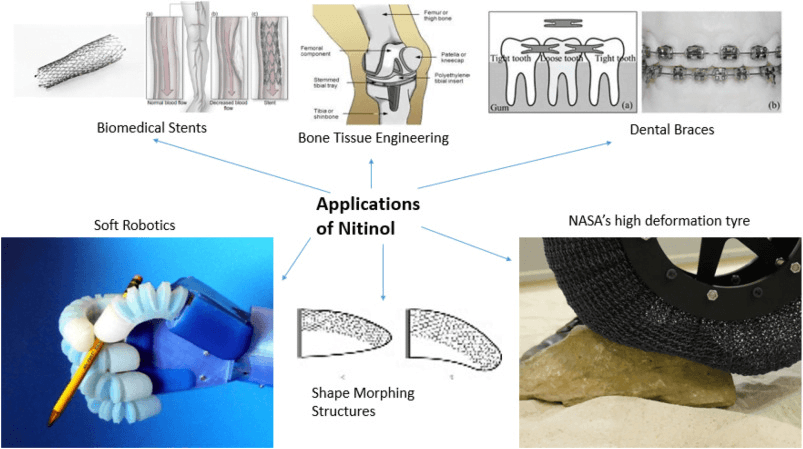

Biomedical Applications: The utilization of NiTi alloy powder is widespread in the biomedical sector, particularly in the production of medical devices and implants. Capitalizing on its shape memory properties, the alloy can be shaped, activated, and deployed within the body. Notable applications encompass stents, orthopedic implants, dental braces, cardiovascular implants, and surgical instruments.

Aerospace and Automotive Industries: NiTi alloy powder plays a vital role in the aerospace and automotive sectors, where it contributes to the manufacturing of components requiring high strength, lightweight characteristics, and exceptional shape memory. Examples include actuators, connectors, engine components, and vibration dampers.

Robotics and Actuators: In robotics and automation, NiTi alloy powder is a key material for producing actuators and shape memory alloys. Its inherent shape memory effect enables precise and controlled movements, making it suitable for applications such as robotic grippers, valves, and micro-actuators.

Electronics and Microtechnology: NiTi alloy powder finds application in microtechnology and electronics, particularly in the creation of microelectromechanical systems (MEMS), microsensors, micro actuators, and other miniature devices demanding precise control and shape memory properties.

Smart Materials: NiTi alloy powder is integrated into smart materials, showcasing unique responses to external stimuli like temperature, stress, or magnetic fields. These materials are employed across various fields, including aerospace, electronics, robotics, and biomedical engineering.

Research and Development: In research and development endeavors, NiTi alloy powder proves invaluable for studying the properties and behavior of shape memory alloys. Its use allows for the creation of prototypes and facilitates exploration into new applications and technologies.

Other NiTiNol Machined Parts

Material: Composition Can be Customized

Shape and Size: According to Data/Drawing

Typical Products: Circlips, Bistable Shape Memory Alloy Rings, Super-elastic Bracelets, Headphone Cables, and More

Properties of NiTiNol Alloy

Mechanical Properties for Superelastic Grades

| Grade | Cold Worked | Superelastic | ||||||

|---|---|---|---|---|---|---|---|---|

| Ingot As (℃) | Min. Uts (psi) | Elongation (%) | Min. Uts (psi) | Elongation (%) | Loading Plateau (ksi) | Unloading Plateau (ksi) | Active Af (℃) | |

| Nitinol #1 | -35 to -10 | 220,000 | >4 | 180,000 | >10 | >70,000 | >20,000 | +10 to +18 |

| Nitinol #2 | -45 to -15 | 250,000 | >4 | 210,000 | >10 | >80,000 | >35,000 | 0 to +18 |

| Nitinol #4 | -10 to +10 | 220,000 | >4 | 180,000 | >10 | >65,000 | >7,000 | +14 to +22 |

| Nitinol #9 | ≥ +35 | 220,000 | >4 | 160,000 | >10 | >75,000 | >25,000 | ≤0 |

Mechanical Properties for Shape-Memory Grades

| Grade | Cold Worked | Superelastic | ||||

|---|---|---|---|---|---|---|

| Ingot As (℃) | Min. Uts (psi) | Elongation (%) | Min. Uts (psi) | Elongation (%) | Active Af (℃) | |

| Nitinol #5 | ≥ +85 | 220,000 | >3 | 160,000 | >10 | ≥ +85 |

| Nitinol #6 | +35 to +85 | 220,000 | >3 | 160,000 | >10 | +40 to +80 |

| Nitinol #8 | +10 to +35 | 220,000 | >3 | 160,000 | >10 | +22 to +40 |

Surface Finishes

Light Oxide (LO) Gold to Brown color – diamond-drawn surface

Dark Oxide (DK) Blue to Black color – diamond drawn surface

Black Oxide (BLK) Shiny Black color – diamond drawn surface

Etch (E) Chemical removal of oxide layer – maintain a smooth surface

Pickled (P) Chemical removal of the oxide layer along with a slight amount of base metal – the surface will have a rough texture. Etched and Mechanically Polished (EMP) Chemical removal of the oxide layer followed by mechanical polish – the surface will have a Stainless-Steel appearance, although at > 40x magnification, micro scratches are present.

Descriptions

Nitinol, which is also known as nickel titanium, is a type of Shape Memory Alloy (SMA) made up of nickel and titanium. It has unique properties that make it useful in a variety of applications. Superelasticity, or pseudoelasticity, allows Nitinol to return to its original shape after being deformed. This characteristic makes it ideal for a range of uses, including medical devices such as stents and heart valves, eyeglass frames, robotics, actuators, and many other engineering and technological fields where shape-memory and superelasticity are beneficial. Nitinol’s shape memory effect enables it to “remember” its shape and change it depending on temperature. Nitinol’s properties arise from the reversible transformations between the austenite and martensite phases, which may be temperature-induced (shape-memory) or stress-induced (pseudoelasticity). The alloy is composed of nearly equal parts of nickel and titanium, with titanium accounting for around 43% to 46%. Nitinol’s unique properties and uses have made it an essential material in robotics and medical devices.

Small changes in the composition of Nitinol, a nickel-titanium alloy, can have a significant impact on its properties. Nitinol can be classified into two primary categories: super elastic alloy (SME) and shape memory alloy (SMA).

Super Elastic (SME) Nitinol exhibits extraordinary recoverable strains and kink resistance due to a stress-induced martensitic transformation. This allows the material to display excellent superelastic properties at body temperature.

Shape Memory Alloy (SMA) Nitinol is valued for its ability to regain a pre-set shape when heated above its transformation temperature. This shape memory effect is due to a phase transformation in the crystal structure when the alloy is heated or cooled, enabling it to revert to its previous shape with great force.

The main products of NiTiNol Alloy (SME and SMA) include wire and rod, sheet foil and plate, springs, spectacle frame/glasses frame, powder, and other machined parts.

Why MetalsTek Engineering

Unlocking the Potential: The Shape-Shifting Magic of NiTinol Alloy

Picture a metal that can remember its original shape, returning to it even after being bent, twisted, or stretched. This isn’t a scene from a sci-fi movie but the reality of NiTinol alloy—a remarkable combination of nickel (approximately 55%) and titanium (about 45%) that offers this almost magical ability. Known for its unique shape memory effect and superelasticity, NiTinol not only piques curiosity but also revolutionizes applications ranging from medical devices to everyday products.

Table of Contents

Chapter 1

NiTinol Alloy Properties

Nitinol, a unique metal alloy, exhibits remarkable properties that make it highly versatile and valuable, particularly in medical applications. One of the key characteristics of nitinol is its shape memory effect and superelasticity. The shape memory effect allows nitinol to be deformed at one temperature, retain its deformed shape when the force is removed, and then recover its original shape when heated above its transformation temperature. This transformation temperature can be precisely tuned by adjusting the nickel-titanium composition, typically between -100°C to +100°C. Nitinol’s superelasticity enables it to undergo large deformations of up to 8% strain and then spring back to its original shape without permanent deformation.

In addition to its unique shape-changing abilities, nitinol also possesses excellent corrosion resistance, with a corrosion rate of less than 0.1 μm/year in saline solutions. It is highly biocompatible, with no known toxic or allergic reactions in the human body. Nitinol’s high strength-to-weight ratio, with a tensile strength of 895 MPa and a density of 6.45 g/cm³, further enhances its versatility.

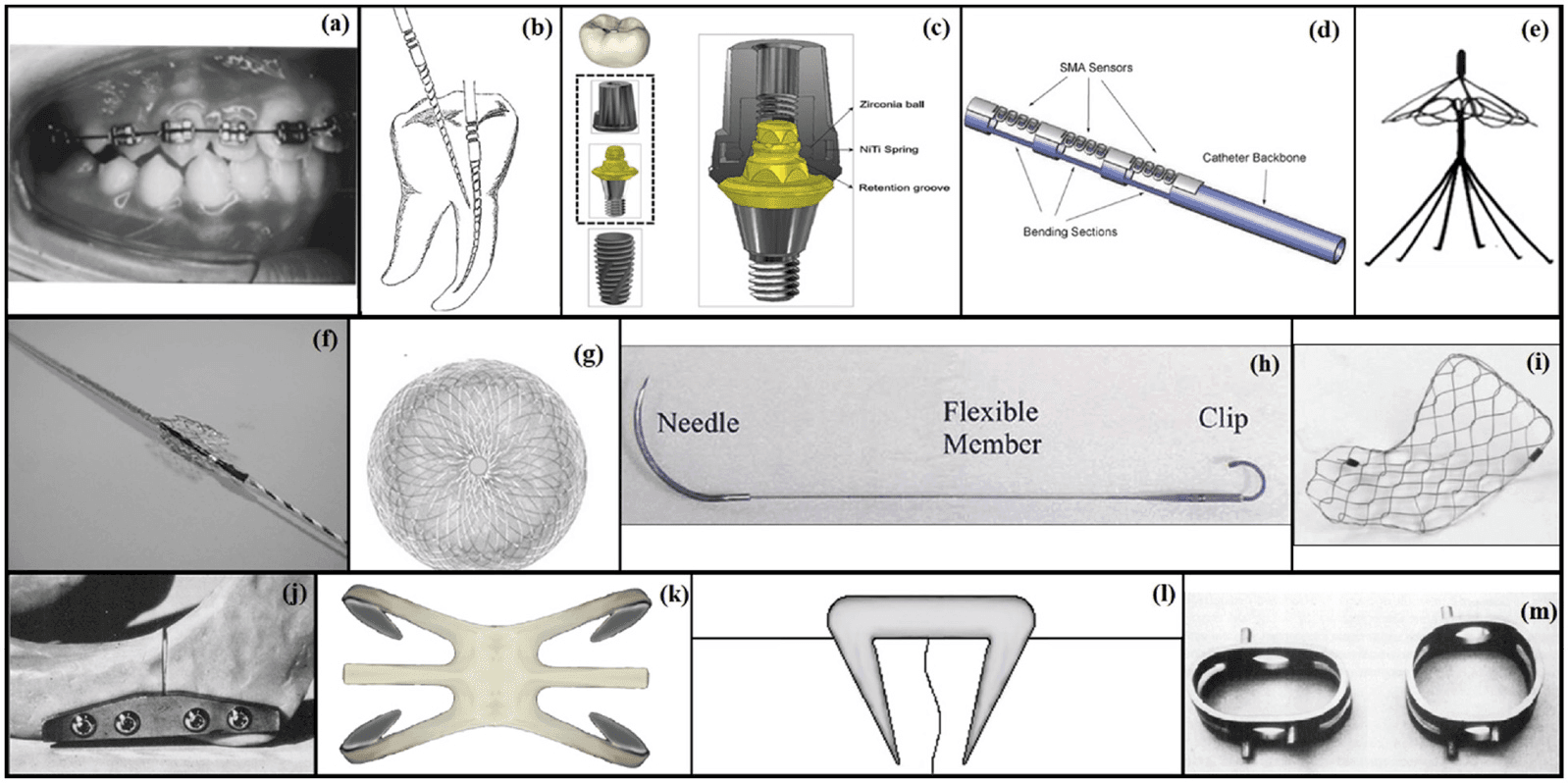

The combination of these properties makes nitinol well-suited for a variety of medical applications, including stents for opening blocked arteries, guidewires for navigating through blood vessels, orthodontic wires and dental implants, and surgical instruments and devices. Mastering the complex metallurgy and processing of nitinol was initially challenging, but advances in melting, fabrication, and heat treatment have enabled widespread commercial use, particularly in the medical field.

Chapter 2

NiTinol in Medical Devices

Nitinol is a commonly used material in the medical device industry due to its unique properties, including superelasticity, shape memory, and biocompatibility. Some key applications of nitinol in medical devices include:

- Cardiovascular devices: Nitinol is extensively used in stents, heart valves, guidewires, and vena cava filters due to its ability to compress to a low profile for minimally invasive delivery and then expand to its original shape.

- Orthodontic devices: Nitinol’s superelastic properties allow it to be used in orthodontic archwires and brackets that can deform and then recover their original shape.

- Surgical instruments: Nitinol instruments can be shaped to the patient’s anatomy and then return to their original straight form during sterilization.

- Orthopedic implants: Nitinol’s shape memory allows it to be compressed for minimally invasive delivery and then expand to its original shape when deployed.

- Neurovascular devices: Nitinol is used in catheters and other devices for minimally invasive procedures in the brain, such as Synchron’s Stentrode brain-computer interface implant.

- Other applications: Nitinol is also used in colorectal surgery, endodontics, surgical robotics, and dissolvable medical devices.

Chapter 3

Industrial Applications of NiTinol

Sensors and Actuators

Nitinol is used extensively in the manufacturing of industrial-grade sensors and actuators. Its shape memory and superelastic properties allow it to be used in components like autofocus actuators in cameras and optical image stabilizers in mobile phones.

Robotics

The unique properties of Nitinol make it an important material for robotics, where it is used in actuators and micromanipulators.

Construction

Nitinol is used in construction applications, particularly in intelligent reinforced concrete (IRC). Engineers embed nitinol wires within the concrete, allowing it to sense cracks and self-heal, improving the durability and strength of structures like skyscrapers and bridges.

Military Applications

The military has used nitinol couplers in F-14 fighter planes since the late 1960s. These couplers join hydraulic lines tightly and easily, taking advantage of nitinol’s shape memory properties.

Chapter 4

NiTinol in Everyday Products

Medical Devices

Nitinol is extensively used in medical devices such as stents, heart valves, orthodontic wires, and guidewires due to its superelastic and shape memory properties.

Household Appliances

Nitinol’s thermal sensitivity is utilized in household appliances like deep fryers, where it is used to lower the basket into the oil at the correct temperature.

Eyewear

Nitinol’s superelasticity and shape memory properties have made it a popular material for eyeglass frames. Nitinol frames offer unmatched flexibility and durability, as they can effortlessly return to their original shape even after significant deformation.

Smart Devices

Nitinol is increasingly finding its way into smart devices, such as smartwatches with shape-changing interfaces and foldable smartphones, taking advantage of its shape memory and superelastic qualities.2

Automotive Applications

Nitinol actuators can be used as engine mounts and suspensions to control vibration, helping prevent damage to automotive structures. Nitinol springs are also envisioned for use in engine cooling, carburetor and engine lubrication controls, and radiator blinds.

Other Everyday Products

Nitinol enables magic spoons from magic shops to bend when placed in hot water, demonstrating its shape memory effect in a playful consumer application.

Chapter 5

Challenges and Limitations

Despite its advantages, working with NiTinol presents certain challenges.

Manufacturing Challenges

- Nitinol is difficult to process and machine due to its high hardness and abrasiveness, requiring specialized techniques like centerless grinding and careful temperature management to prevent deformation.

- The shape-setting process for nitinol can present logistical challenges, requiring additional space and equipment compared to other materials.

Material Properties

- Nitinol is not as strong as some traditional metals like steel, limiting its use in certain high-strength applications.

- The superelasticity and shape memory properties of nitinol can be sensitive to temperature changes, requiring careful control during manufacturing and use.

Cost

- Nitinol is more expensive than traditional metals like steel and aluminum, which can be a barrier for some applications.

Biocompatibility Concerns

- The nickel content in nitinol can potentially cause biocompatibility issues if not carefully controlled, requiring thorough testing and evaluation.

Chapter 6

Price and Factors Influencing NiTinol Alloy Cost

The price of NiTinol alloy is influenced by several factors, primarily the costs of nickel and titanium, which are its main components. Market prices for nickel can range from $15,000 to $20,000 per ton, while titanium can cost between $3,000 and $6,000 per ton, depending on market fluctuations. Additional factors include processing costs, the complexity of the manufacturing process, and demand in sectors such as medical and aerospace industries, which can drive prices higher. Generally, the price for NiTinol alloy ranges from $300 to $500 per kilogram, varying with purity and the specific requirements of the application.

Chapter 7

Prospects of NiTinol Alloys

Looking to the future, the potential applications of NiTinol continue to expand. Researchers are exploring its use in robotics, particularly for developing ‘muscle wires’ that act as artificial muscles, providing robots with the ability to move with a new level of finesse. Such innovations could revolutionize the robotics industry, paving the way for more advanced, capable, and adaptable robots.

Moreover, recent developments in additive manufacturing techniques have helped overcome some of the traditional challenges in nitinol processing, such as machining difficulties. This is opening up new design possibilities and improving productivity for nitinol-based products across industries.

Chapter 8

Conclusion

NiTinol alloy is not just a material but a pivotal innovation in material science. Its ability to remember and return to its original shape opens up a world of possibilities across various sectors. From life-saving medical devices to enhancing the comfort and durability of everyday products, NiTinol continues to demonstrate its worth as a magical, transformative material that pushes the boundaries of technology and improves our daily lives.