Menu

MetalsTek Engineering (MetalsTek) is a leading manufacturer and supplier of Aluminum Alloys. We can produce Aluminum Alloys according to our customer’s requests.

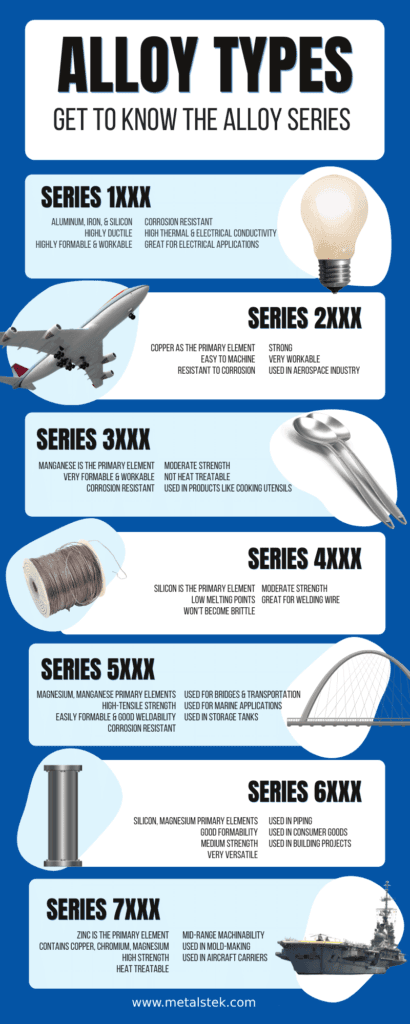

Aluminum Alloys are special materials made primarily of aluminum, as well as other alloying elements like copper, magnesium, zinc, and silicon. These additional elements enhance certain properties that are useful for different applications. Aluminum Alloys combine the lightweight nature of aluminum with features like strength, corrosion resistance, and formability. They are incredibly versatile and are used in several industries such as aerospace, automotive, construction, marine, electronics, and consumer goods. Aluminum Alloys find their use in structural components, machinery parts, packaging, and decorative finishes. There are several popular aluminum alloys available, such as 6061, 7075, 2024, 5052, and 5083. Each alloy is tailored to meet specific requirements like strength, machinability, corrosion resistance, and thermal conductivity. Aluminum Alloys are highly adaptable and play a crucial role in modern manufacturing, driving innovation and advancements in engineering solutions.

MetalsTek supplies various of Aluminum Alloys. And most of the alloys are with various forms, such as powder, ingot, spherical powder, wire, rod, sheet, etc. Below is the alloy list. Feel free to click the one to inquire.

Some typical Aluminum Alloys include:

Aluminum Alloys are renowned for their lightweight yet strong characteristics, making them indispensable across various industries. Here are some of the primary applications of aluminum alloys:

These applications demonstrate the versatility and widespread use of Aluminum Alloys across multiple industries, driven by their unique combination of properties.

Our Aluminum Alloys clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.