Menu

MetalsTek Engineering is a leading supplier of high-quality Molybdenum Crucibles and Boats. We can manufacture various diameter, height, and thickness molybdenum crucibles and boats to suit our customers’ needs.

Material: Molybdenum (Mo)

Purity: Mo≥99.95%

Density: 9.8~10.2 g/cc

Standard: ASTM B387

Size Range: Sintered Type Dia. 10~500mm * Height 10~600mm

Forged Type Dia.10~130mm * Height 10~200mm

Type: Milled Type, Spin-formed Type, Pressed and Sintered Type, Welded Type

Applications

Molybdenum crucibles, renowned for their exceptional corrosion resistance to various acids and molten materials like glass or metals, prove highly beneficial in metallurgical, mechanical, and rare earth smelting industries. These crucibles excel in applications such as vacuum thermal evaporation, nuclear fuel sintering, and capacitor sintering. Additionally, they find utility in LED Sapphire Crystal Growing, the chemical industry, and the burgeoning high-technology sector, including crystalloid materials.

Material: Molybdenum (Mo)

Purity: Mo≥99.95%

Density: 9.8~10.2 g/cc

Standard: ASTM B387

Size Range: Sintered Type Dia. 10~500mm * Height 10~600mm

Forged Type Dia.10~130mm * Height 10~200mm

Type: Straight-Wall Type, Milled Type, Spin-formed Type, Pressed and Sintered Type, Welded Type

| Model | Capacity (mL) | Outside Diameter (mm) | Depth (mm) |

|---|---|---|---|

| MoC-1000 | 1000 | 127 | 89 |

| MoC-100 | 100 | 59 | 45 |

| MoC-10 | 10 | 27 | 22 |

| MoC-15 | 15 | 33 | 22 |

| MoC-20 | 20 | 33 | 29 |

| MoC-25 | 25 | 45 | 22 |

| MoC-35 | 35 | 46 | 29 |

| MoC-45 | 45 | 46 | 34 |

| MoC-55 | 55 | 47 | 41 |

| MoC-5 | 5 | 21 | 18 |

| MoC-75 | 75 | 51 | 41 |

Applications

Molybdenum crucibles, renowned for their exceptional corrosion resistance to various acids and molten materials like glass or metals, prove highly beneficial in metallurgical, mechanical, and rare earth smelting industries. These crucibles excel in applications such as vacuum thermal evaporation, nuclear fuel sintering, and capacitor sintering. Additionally, they find utility in LED Sapphire Crystal Growing, the chemical industry, and the burgeoning high-technology sector, including crystalloid materials.

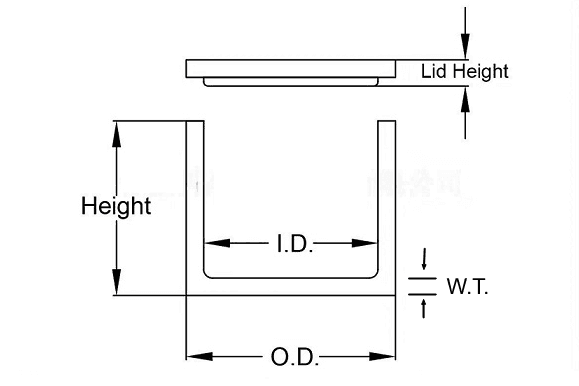

Material: Molybdenum (Mo) or TZM, or Other Materials

Standard: ASTM B387

Size Range: Sintered Type Dia. 10~500mm * Height 10~600mm

Forged Type Dia.10~130mm * Height 10~200mm

Type: Straight-Wall Type, Milled Type, Spin-formed Type, Pressed and Sintered Type, Welded Type

The Molybdenum Crucible is crafted from Mo-1 Molybdenum powder, designed to withstand temperatures ranging from 1,100°C to 1,700°C and primarily utilized in the metallurgical industry, rare earth industry, monocrystalline silicon production, solar energy applications, artificial crystal manufacturing, and mechanical processing industries.

We offer two types of molybdenum crucibles. The first is a sintered product with a 9.8 to 10 g/cc density. The second is a forged product with a density of up to 10.2 g/cc.

| Item No. | Outer Diameter (mm) | Wall Thickness (mm) | Height (mm) |

|---|---|---|---|

| MOC-01 | 10 ~ 30 | 1.0 ~ 3 | 20 ~ 50 |

| MOC-02 | 30 ~ 50 | 2~ 10 | 20 ~ 100 |

| MOC-03 | 50 ~ 100 | 3 ~ 15 | 30 ~ 150 |

| MOC-04 | 100 ~ 150 | 3 ~ 15 | 30 ~ 500 |

| MOC-05 | 150 ~ 200 | 5 ~ 20 | 30 ~ 500 |

| MOC-06 | 200 ~ 300 | 8 ~ 20 | 30 ~ 500 |

| MOC-07 | 300 ~ 400 | 8 ~ 30 | 40 ~ 500 |

| MOC-08 | 400 ~ 450 | 8 ~ 30 | 50 ~ 500 |

| MOC-09 | 450 ~ 620 | 8~ 30 | 50 ~ 500 |

| Shape and size can be tailored. Rectangular Molybdenum crucible is available. | |||

Molybdenum Crucibles and Molybdenum Boats are crucial in various high-temperature applications, especially in thin film deposition and evaporation processes.

Molybdenum Boats exhibit properties inherited from their source material, whether pure or molybdenum or alloy. Crafted from processed molybdenum plates subjected to cutting, folding, riveting, and welding, these boats offer versatile customization options, such as square, rectangular, round, trapezoidal, and more, catering to customer specifications.

The suitability of Molybdenum Boats for evaporation materials arises from molybdenum’s exceptional tolerance to low and high temperatures, a feature not shared by many other elements. This resilience makes them particularly effective for use as boats in furnace machines. Beyond evaporation applications, molybdenum boats find utility in diverse sectors, including the rare earth industry, nuclear fuel sintering, and capacitor-discharged sintering.

Molybdenum Crucibles and Boats are crucial in various high-temperature applications, especially thin film deposition and evaporation.

Here are some critical points about Molybdenum Crucibles and Boats for evaporation:

Molybdenum Crucibles and Boats are essential components in the deposition industry, providing a reliable and durable solution for the controlled evaporation of materials in vacuum environments. The choice of molybdenum ensures high performance and longevity in demanding applications.

Our Molybdenum Crucible & Boat are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.