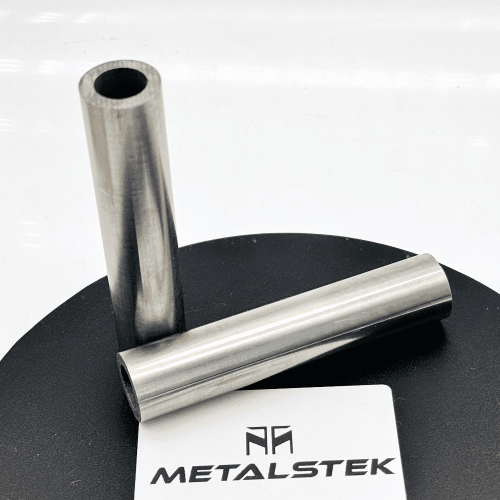

The Advantages of Tungsten Tubes: A Complete Guide for Technological Applications

Tungsten tubes have gained significant popularity in the world of technological applications due to their numerous advantages. From their high melting point and excellent electrical conductivity to their corrosion resistance and durability, tungsten tubes offer a wide range of benefits for various industries.

With their exceptional heat resistance, tungsten tubes are ideal for applications where extreme temperatures are involved. They can withstand temperatures up to 3,400 degrees Celsius, making them an excellent choice for high-temperature environments such as furnaces and incandescent lighting.

Furthermore, tungsten tubes exhibit remarkable electrical conductivity, making them indispensable in electronic devices and electrical wiring. Their low thermal expansion coefficient also ensures stability and reliability under fluctuating temperature conditions.

Additionally, tungsten tubes possess exceptional corrosion resistance, making them suitable for harsh and corrosive environments. Industries such as chemical processing and oil and gas rely on tungsten tubes to withstand aggressive substances and extreme conditions.

In conclusion, the advantages of tungsten tubes are undeniable when it comes to technological applications. Their robustness, high heat resistance, electrical conductivity, and corrosion resistance make them a valuable asset across various industries.

Table of Contents

Chapter 1

Properties and Characteristics of Tungsten Tubes

Moreover, tungsten has an exceptionally high density, which provides strength and durability to the tubes. This density also contributes to its excellent electrical conductivity, making it an ideal choice for applications requiring high electrical performance.

In addition, tungsten has a low thermal expansion coefficient, meaning it expands and contracts minimally under temperature fluctuations. This characteristic ensures the stability and reliability of tungsten tubes in various technological applications, even when exposed to extreme temperature changes.

The corrosion resistance of tungsten tubes is another notable property. Tungsten is highly resistant to corrosion by most acids, alkaline solutions, and organic chemicals, making it suitable for use in harsh and corrosive environments.

Overall, the properties and characteristics of tungsten tubes make them a versatile and reliable material for a wide range of technological applications.

Chapter 2

Advantages of Using Tungsten Tubes in Technological Applications

- High Heat Resistance: One of the primary advantages of tungsten tubes is their exceptional heat resistance. They can withstand temperatures up to 3,400 degrees Celsius without deformation or structural damage. This makes them ideal for applications such as incandescent lighting, furnaces, and high-temperature processing.

- Excellent Electrical Conductivity: Tungsten tubes exhibit excellent electrical conductivity, making them an essential component in electronic devices and electrical wiring systems. The high electrical performance of tungsten ensures efficient transmission of electricity, reducing power loss and improving overall system performance.

- Corrosion Resistance: Tungsten tubes are highly resistant to corrosion, making them suitable for use in harsh and corrosive environments. They can withstand exposure to aggressive substances, acids, and alkaline solutions without degradation. Industries such as chemical processing, oil and gas, and mining rely on tungsten tubes to withstand the corrosive nature of their operations.

- Durability and Longevity: Tungsten tubes are known for their exceptional durability and longevity. They have a high resistance to wear and tear, making them suitable for applications where reliability and longevity are crucial. Tungsten tubes can withstand repeated use and exposure to extreme conditions without significant degradation or performance loss.

- Stability Under Fluctuating Temperatures: Tungsten tubes have a low thermal expansion coefficient, meaning they expand and contract minimally under temperature fluctuations. This characteristic ensures the stability and reliability of tungsten tubes in applications where temperature changes are common. They maintain their structural integrity and performance even when exposed to rapid temperature changes.

- Non-Toxic and Environmentally Friendly: Tungsten is a non-toxic and environmentally friendly material, making tungsten tubes a safe choice for various applications. Unlike some other metals, tungsten does not leach harmful substances into the environment, making it suitable for use in industries that prioritize environmental sustainability.

The advantages of using tungsten tubes in technological applications are undeniable. From their high heat resistance and excellent electrical conductivity to their corrosion resistance, durability, and stability under fluctuating temperatures, tungsten tubes offer numerous benefits that make them a preferred choice in various industries.

Chapter 3

Applications of Tungsten Tubes in Various Industries

- Lighting Industry: Tungsten tubes find extensive use in the lighting industry, particularly in incandescent lighting applications. The high heat resistance of tungsten allows for the efficient conversion of electrical energy into light, making these tubes ideal for use in incandescent light bulbs.

- Electronics and Electrical Engineering: Tungsten tubes are widely used in electronics and electrical engineering applications. Their excellent electrical conductivity makes them suitable for electrical wiring, high-power electronic devices, and components such as cathode-ray tubes and X-ray tubes.

- Chemical Processing: Tungsten tubes are highly resistant to corrosion, making them suitable for use in chemical processing applications. They can withstand exposure to aggressive substances, acids, and alkaline solutions, making them an ideal choice for reactors, heat exchangers, and other equipment used in chemical processing plants.

- Oil and Gas Industry: The oil and gas industry often operates in harsh and corrosive environments. Tungsten tubes’ corrosion resistance and durability make them a preferred choice for applications such as oil well drilling, refining, and transportation. They can withstand the corrosive nature of oil and gas operations, ensuring reliable performance even in challenging conditions.

- Heat Treatment and Furnaces: Tungsten tubes’ high heat resistance makes them ideal for heat treatment and furnace applications. They are used in high-temperature furnaces for processes such as annealing, sintering, and heat treating metals. Tungsten tubes can withstand the extreme temperatures involved in these processes without deformation or structural damage.

- Aerospace and Defense: The aerospace and defense industries require materials that can withstand extreme conditions and provide reliable performance. Tungsten tubes’ high heat resistance, electrical conductivity, and corrosion resistance make them suitable for various applications in these industries, including rocket nozzles, aircraft engine components, and missile guidance systems.

The wide range of applications for tungsten tubes across different industries showcases their versatility and reliability in meeting the unique requirements of technological applications.

Chapter 4

Manufacturing Process of Tungsten Tubes

1. Raw Material Preparation

- Tungsten Powder: The raw material for producing tungsten tubes is high-purity tungsten powder, typically requiring a purity of 99.95% or higher. The quality of the tungsten powder directly affects the performance of the final product.

- Mixing: Depending on requirements, a small amount of other elements or alloy components may be added to improve the characteristics of the tungsten tube.

2. Powder Metallurgy

- Mixing: Tungsten powder and other necessary additives are evenly mixed to ensure uniformity.

- Pressing: The mixed tungsten powder is pressed into shape using an isostatic press, forming a tungsten billet. This step requires high pressure to ensure the billet’s density and uniformity.

3. High-Temperature Sintering

- Sintering: The pressed tungsten billet is placed in a high-temperature furnace for sintering under a hydrogen atmosphere or in vacuum conditions. The sintering temperature is usually above 2000°C, and the sintering time depends on the billet size and required density.

- Cooling: After sintering, the billet is slowly cooled to prevent stress cracks.

4. Mechanical Processing

- Turning: The sintered tungsten billet is initially turned to obtain a rough shape close to that of a tungsten tube.

- Drilling and Reaming: Specialized drills and reaming tools are used to drill and ream the tungsten billet, gradually achieving the required inner diameter.

5. Chemical Mechanical Polishing

- Chemical Treatment: The roughly processed tungsten tube undergoes chemical treatment to remove surface oxides and impurities.

- Polishing: A combination of mechanical polishing and chemical polishing further enhances the surface smoothness and precision of the tungsten tube, ensuring it meets usage requirements.

6. Inspection and Quality Control

- Dimensional Inspection: Precision measurement tools are used to check the outer diameter, inner diameter, and wall thickness of the tungsten tube, ensuring they meet design specifications.

- Physical Properties Testing: Hardness, density, tensile strength, and other physical properties are tested to ensure the tungsten tube possesses the required mechanical properties.

- Non-Destructive Testing: Ultrasonic, X-ray, and other non-destructive testing methods are used to check for internal cracks or defects in the tungsten tube.

7. Post-Processing and Packaging

- Cleaning: The qualified tungsten tube undergoes final cleaning to remove any remaining processing fluids and impurities.

- Surface Treatment: Depending on customer requirements, passivation or coating may be applied to further enhance the corrosion resistance of the tungsten tube.

- Packaging: The processed tungsten tubes are packaged according to specifications to prevent damage during transportation and are labeled according to customer requirements.

Through these steps, high-quality and high-performance tungsten tubes are produced to meet the needs of various industries. The production of tungsten tubes requires not only advanced craftsmanship but also stringent quality control to ensure the performance and reliability of the final product.

Chapter 5

Factors to Consider When Choosing Tungsten Tubes

When selecting tungsten tubes for a specific application, several factors should be taken into consideration to ensure the optimal performance and longevity of the tubes.

- Temperature Requirements: Consider the temperature range the tubes will be exposed to in the application. Tungsten tubes have different temperature limits, and choosing a tube that can withstand the required temperature range is crucial.

- Corrosion Resistance: Evaluate the environment in which the tubes will be used. Consider the corrosive substances or chemicals present and choose tungsten tubes with the appropriate corrosion resistance properties.

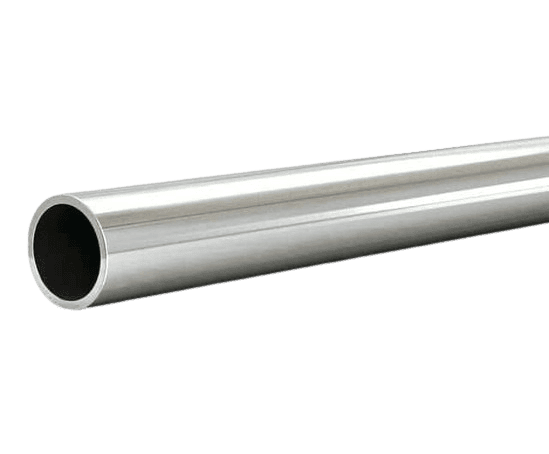

- Dimensions and Tolerances: Ensure the tungsten tubes’ dimensions and tolerances meet the specific requirements of the application. Consider factors such as length, diameter, wall thickness, and straightness to ensure a proper fit and optimal performance.

- Electrical Conductivity: If the application requires high electrical conductivity, consider the electrical properties of the tungsten tubes. Different grades of tungsten tubes have varying electrical conductivity levels, so choose the grade that meets the application’s requirements.

- Cost and Availability: Consider the cost and availability of the tungsten tubes. Evaluate the budget and the availability of the tubes from reputable suppliers to ensure a reliable supply chain.

By considering these factors, one can select the most suitable tungsten tubes for a specific application, ensuring optimal performance and longevity.

Chapter 6

Comparison of Tungsten Tubes with Other Materials

Tungsten tubes offer several advantages over other materials commonly used in technological applications. Let’s compare tungsten tubes with two widely used materials: stainless steel and ceramic.

- Heat Resistance: Tungsten tubes have a much higher heat resistance compared to stainless steel and ceramic. While stainless steel can withstand relatively high temperatures, it falls short of tungsten’s exceptional heat resistance. Ceramic materials have varying heat resistance depending on the type, but they are generally lower than tungsten.

- Electrical Conductivity: Tungsten tubes exhibit excellent electrical conductivity, surpassing both stainless steel and ceramic materials. Stainless steel has moderate electrical conductivity, while ceramic materials are typically insulators and have low electrical conductivity.

- Corrosion Resistance: Tungsten tubes excel in corrosion resistance, outperforming both stainless steel and ceramic materials. Stainless steel is susceptible to corrosion, especially in aggressive environments, while ceramic materials can be prone to chemical attack and degradation.

- Durability and Longevity: Tungsten tubes offer exceptional durability and longevity compared to stainless steel and ceramic materials. Stainless steel can degrade over time due to corrosion, and ceramic materials can be brittle and prone to cracking or breaking under certain conditions.

- Cost: Tungsten tubes tend to be more expensive compared to stainless steel and ceramic materials. However, considering their superior properties and longevity, the higher cost can be justified in applications that require the unique advantages offered by tungsten.

While stainless steel and ceramic materials have their own advantages and applications, tungsten tubes surpass them in terms of heat resistance, electrical conductivity, corrosion resistance, durability, and longevity.

Chapter 7

Maintenance and Care of Tungsten Tubes

Proper maintenance and care of tungsten tubes can help extend their lifespan and ensure optimal performance over time. Here are some tips for maintaining and caring for tungsten tubes:

- Regular Cleaning: Regularly clean the tungsten tubes to remove any dirt, dust, or contaminants that may accumulate on the surface. Use a soft cloth or sponge and mild detergent to clean the tubes gently. Avoid using abrasive cleaners or materials that could scratch or damage the surface.

- Avoid Impact or Rough Handling: Tungsten tubes are durable, but they can still be susceptible to damage from impact or rough handling. Handle the tubes with care and avoid dropping or subjecting them to excessive force or pressure.

- Monitor for Corrosion or Damage: Regularly inspect the tungsten tubes for signs of corrosion or damage. If any corrosion or damage is detected, take appropriate measures to address the issue promptly. Depending on the extent of the corrosion or damage, it may be necessary to replace the affected tubes.

- Store Properly: When not in use, store the tungsten tubes in a clean and dry environment. Avoid exposing them to excessive moisture, extreme temperatures, or corrosive substances. Proper storage helps prevent degradation and ensures the tubes are in optimal condition when needed.

- Follow Manufacturer’s Guidelines: Follow any specific maintenance and care guidelines provided by the manufacturer of the tungsten tubes. These guidelines may include specific cleaning procedures, storage recommendations, and other instructions to ensure the optimal performance and longevity of the tubes.

By following these maintenance and care practices, one can maximize the lifespan and performance of tungsten tubes, ensuring they continue to deliver the desired advantages in technological applications.

Chapter 8

Where to Buy Tungsten Tubes

When looking to purchase tungsten tubes, it is essential to source them from reputable suppliers to ensure the quality and reliability of the product. Here are some options for purchasing tungsten tubes:

- Specialty Metal Suppliers: Specialty metal suppliers often offer a wide range of tungsten products, including tubes. These suppliers specialize in providing high-quality metals and alloys for various industries and applications.

- Online Marketplaces: Online marketplaces such as Alibaba, Amazon, or eBay can be a convenient option for purchasing tungsten tubes. However, it is crucial to research the sellers and ensure they have a good reputation and positive customer reviews.

- Local Metal Suppliers: Local metal suppliers may carry tungsten tubes or be able to source them for specific requirements. Contacting local suppliers allows for direct communication and the possibility of discussing specific needs or custom orders.

- Industrial Trade Shows and Exhibitions: Attending industrial trade shows and exhibitions related to the specific industry or application can provide an opportunity to connect with suppliers of tungsten tubes. These events often feature a wide range of suppliers and manufacturers showcasing their products.

When purchasing tungsten tubes, it is important to consider factors such as the supplier’s reputation, product quality, pricing, and customer support. Requesting samples or technical specifications can help evaluate the suitability of the tungsten tubes for the intended application.