Menu

MetalsTek Engineering is a professional supplier of Tungsten Carbides. We offer our products at high quality and competitive prices.

Tungsten carbide powder (WC) serves as the main ingredient in the production of cemented carbide. It appears as a black six-square crystal with a metallic luster and boasts a hardness akin to a diamond. Notably, it is an excellent conductor of both electricity and heat. With a melting point of 2,870°C and a boiling point of 6,000°C, tungsten carbide finds extensive industrial use in metal drilling, turning, and milling, primarily through carbide tools.

Material: Tungsten Carbide (WC)

Purity: WC-99.9% Min

Hardness: 93-93.7 HRA

Density: 16.5 g/cc

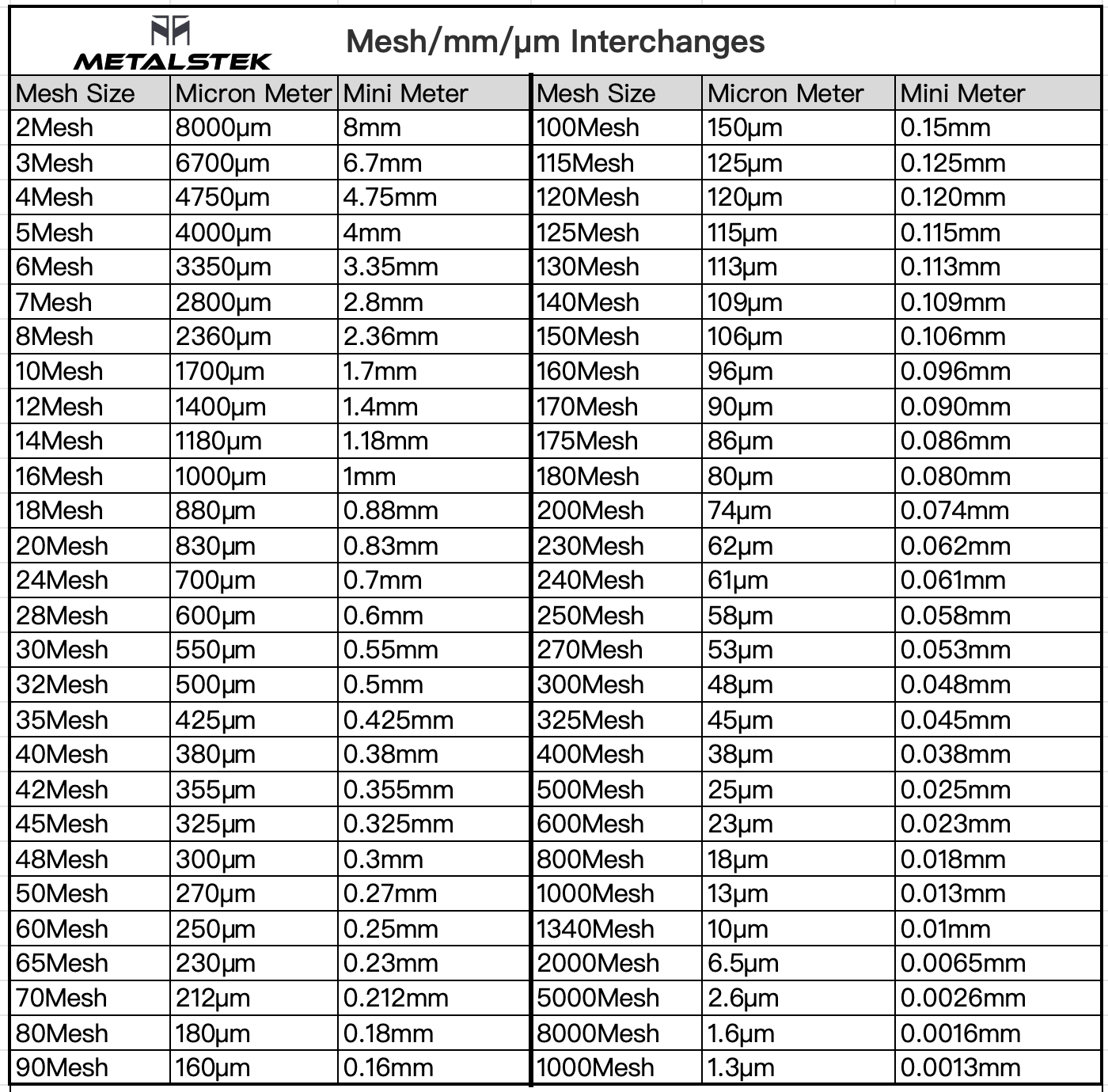

Particle: 0.4-60μm, Can be Customized

Morphology: Hexagonal

Melting Point: 2,870℃ / 5,198F

CAS #: 12070-12-1

Other: Spherical and Cast Tungsten Carbide Powder Available

| Classified | Grade | Particle Size (BET/μm) | Carbon Ratio (%) | Total Carbon (%) | Main Impurity | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ultra-Fine Powder | WC02 | BET: ≥2.5 | ≤0.15 | 6.20±0.05 | O≤0.50 | |||||||

| WC05 | BET: 1.9-2.5 | ≤0.12 | 6.20±0.05 | O≤0.35 | ||||||||

| WC07 | 0.60-0.80 | ≤0.10 | 6.18±0.05 | O≤0.25 | ||||||||

| Fine Powder | WC10 | 0.90-1.50 | ≤0.06 | 6.15±0.05 | O≤0.15 | |||||||

| WC15 | 1.50-2.00 | ≤0.06 | 6.13±0.05 | O≤0.12 | ||||||||

| WC20 | 2.00-2.50 | ≤0.05 | 6.13±0.05 | O≤0.10 | ||||||||

| Medium-Fine Powder | WC25 | 2.50-3.00 | ≤0.05 | 6.13±0.05 | O≤0.07 | |||||||

| WC30 | 3.00-4.00 | ≤0.05 | 6.13±0.05 | O≤0.05 | ||||||||

| WC40 | 4.00-5.00 | ≤0.05 | 6.13±0.05 | O≤0.04 | ||||||||

| WC50 | 5.00-6.00 | ≤0.05 | 6.13±0.05 | O≤0.03 | ||||||||

| WC60 | 6.00-8.00 | ≤0.05 | 6.13±0.05 | O≤0.04 | ||||||||

| Coarse Powder | WC80 | 8.00-10.00 | ≤0.05 | 6.13±0.05 | O≤0.04 | |||||||

| WC100 | 10.00-15.00 | ≤0.05 | 6.13±0.05 | O≤0.03 | ||||||||

| Extra-Coarse Powder | WC150 | 15.00-20.00 | ≤0.05 | 6.13±0.05 | O≤0.03 | |||||||

| WC200 | 20.00-30.00 | ≤0.05 | 6.13±0.05 | O≤0.03 | ||||||||

| WC400 | 30.00-40.00 | ≤0.05 | 6.13±0.05 | O≤0.03 | ||||||||

| WC600 | 40.00-60.00 | ≤0.05 | 6.13±0.05 | O≤0.03 |

Material: Tungsten Carbide Alloy

Alloy Types: Tungsten Carbide Cobalt Powder (WC/Co), Tungsten Carbide Nickel Powder (WC/Ni), Tungsten Carbide Cobalt Chromium (WC/Co/Cr), Tungsten Carbide Nickel Chromium (WC/Ni/Cr)

Tungsten carbide powder (WC) serves as the main ingredient in the production of cemented carbide. It appears as a black six-square crystal with a metallic luster and boasts a hardness akin to a diamond. Notably, it is an excellent conductor of both electricity and heat. With a melting point of 2,870°C and a boiling point of 6,000°C, tungsten carbide finds extensive industrial use in metal drilling, turning, and milling, primarily through carbide tools.

Material: Tungsten Carbide-Cobalt (WC-Co)

Purity: WC 85-94%

Density: 14-15.2 g/cc

Surface: Grinding

Rod Type: PCB Rod / Blank Rod

Size Ranges: PCB Rod – Dia.3.25~7mm * Length 12~40mm

Blank Rod – Dia.1.0~42mm * Length 30~700mm

Other: Tungsten Carbide Rod with One or Two Holes Available

Cemented Tungsten Carbide Strip is a sintered metallurgical product of powder form. It is manufactured in vacuum or Hydrogen reduction furnaces with refractory Tungsten material (WC) micron powder as the main ingredient and Cobalt (Co), Nickel (Ni), or Molybdenum (Mo) as the binder.

Material: Tungsten Carbide-Cobalt (WC-Co)

Purity: WC 85-94%

Density: 14-15.2 g/cc

Surface: Grinding

Size Ranges: Thickness 1~20mm, Width 2~40mm, Length 10~200mm

Other: Size Can be Customized

A Tungsten Carbide Drill is composed of an equal ratio of tungsten and carbon atoms. Initially presenting as a fine gray powder, this compound can be shaped through a method known as sintering, enabling its application in industrial machinery, cutting tools, abrasives, armor-piercing bullets, and even jewelry. Renowned for its exceptional hardness, tungsten carbide drills find utility in demanding sectors such as mining, tunneling, and construction industries.

Material: Tungsten Carbide-Cobalt (WC-Co)

Purity: WC 85-94%

Density: 14-15.2 g/cc

Surface: Grinding

Drill Types: PCB Drill, Slot Drill, Step Drill

Size Ranges: PCB Drill – Dia.0.2~3.175mm * Depth 3.5~12.2mm

Slot Drill – Dia.0.4~3.0mm * Depth 5.0~8.7mm

Step Drill – Dia.3.2~6.5mm * Depth 12.5mm

Tungsten Carbide Cutters & Tips are well-suited for shaping, smoothing, or grinding challenging materials such as hardened steel, stainless steel, cast iron, nonferrous metals, fired ceramics, plastics, and hardwoods.

MetalsTek Engineering specializes in crafting personalized Tungsten Carbide Cutters, Saw Tips, Carbide Brazed Tips, and Mining Tips tailored to your specific requirements.

Material: Tungsten Carbide-Cobalt (WC-Co)

Purity: WC 85-94%

Density: 14.5-15.6 g/cc

Surface: Grinding

Size: Customized

Other: Can be Customized

Material: Tungsten Carbide / Alloys

Product: As Requested

Remark: Tungsten Carbide can be used for various products; you can feel free to contact our salesperson to custom according to your applications. The products including Grinding Jars and Balls, Mortar and Pestle, Dies, etc.

Tungsten carbide often denoted as WC is a compound comprised of tungsten and carbon atoms. This chemical compound is renowned for its exceptional hardness and wear resistance. It is an ideal material for cutting tools, drilling bits, milling inserts, and other applications where resistance to abrasion and wear is critical.

The compound’s exceptional toughness and thermal stability further contribute to its widespread use. Its ability to withstand high temperatures without losing its hardness makes it suitable for applications in high-speed machining and other demanding environments.

Tungsten Carbide products include Tungsten Carbide (WC) Powder, Spherical Cast Tungsten Carbide Powder, Macro Tungsten Carbide Powder, Tungsten Carbide Rod, Plate, Tungsten Carbide Die, Drill, Cutter and Tips, Tungsten Carbide Alloys.

Tungsten Carbide is a remarkable material with diverse applications due to its hardness, durability, and thermal stability. Widely used in various industries, from cutting tools and abrasives to industrial machinery and mining applications, Tungsten Carbide has proven indispensable for tasks requiring precision, wear resistance, and resilience in harsh conditions. Its unique properties make it a key player in enhancing the performance and longevity of tools and components across a spectrum of industrial and technological domains. The continued exploration of Tungsten Carbide’s potential and evolving applications further solidifies its position as a critical material in modern engineering and manufacturing.

Our Tungsten Carbide Products are meticulously tagged and externally labeled, ensuring both efficient identification and rigorous quality control. We prioritize utmost care to prevent any potential damage that may occur during storage or transportation.