Menu

MetalsTek Engineering is a leading supplier of Chromium Evaporation Materials. We offer competitive pricing and great lead times on all our materials, and we’re capable of supplying custom materials per any specs/drawings you provide us with. The main Chromium Evaporation Material include Chromium Pellets Pieces, Chromium Alloy Evaporation Materials, Chromium Oxide Evaporation Materials, and Chromium Compound Evaporation Materials.

Material: Chromium, CAS# 7440-47-3

Purity: Cr 99.5% ~ 99.99%

Properties: 7.19g/cc Density, 1,875°C M.P., 9 Mohs Hardness

Form: Pieces, Pellets, Powder

Size: 3*3mm, 6*6mm, or Customized

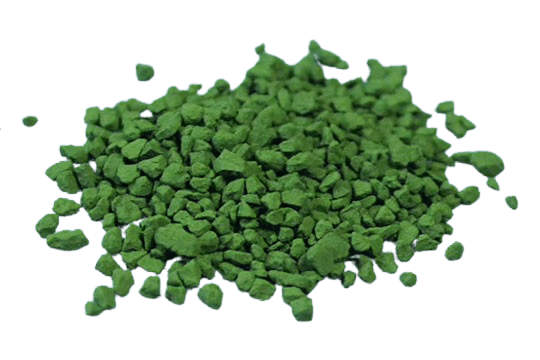

Material: Chromium Oxide

Purity: 99.5% ~ 99.99%

Properties: 5.22g/cc Density, 2,435°C M.P.

Form: Pieces, Pellets, Powder

Size: Customized Size

Material: Chromium Carbide

Purity: 99.5%

Properties: 6.68g/cc Density, 1,895°C M.P.

Form: Pieces, Powder, or Customized

Size: Customized Size

Material: Cr2N, CrF3, CrSi2, Cr2S3, CrB2, and More

Purity: 99.5%, 99.9%

Form: Pellets, Pieces, Powder, or Customized

Size: Customized Sizes

Material: Chromium Aluminum Alloy

Purity: Cr 99.9% ~ 99.99%, Customized Compositions

Form: Pieces, Pellets, Powder

Size: 3*3mm, 6*6mm, or Customized

Aluminum Chromium (Cr/Al, Al/Cr) Evaporation Materials are a combination of aluminum and chromium that are carefully blended in precise proportions to create solid substances for thin film deposition techniques such as physical vapor deposition (PVD) or thermal evaporation.

These materials are widely used in various industries, such as electronics, optics, and coatings. They are heated within a vacuum chamber until they reach their vaporization point, after which the resulting vapor condenses onto a substrate, forming a thin film or coating with desired properties.

Aluminum Chromium (Cr/Al, Al/Cr) Evaporation Materials harness the unique qualities of aluminum and chromium. Aluminum, known for its lightweight nature, has excellent thermal conductivity and high reflectivity. On the other hand, chromium offers exceptional corrosion resistance, hardness, and a notably high melting point.

By carefully blending aluminum and chromium in specific ratios, these evaporation materials can be customized to meet specific requirements. They enable the production of thin films with improved reflectivity, electrical conductivity, corrosion resistance, mechanical strength, and other desirable characteristics.

Applications

Chromium Aluminum (Cr/Al, Al/Cr) Evaporation Materials find widespread use in electronics, optics, and coatings industries. They undergo heating within a vacuum chamber until reaching vaporization temperature. The resulting vapor condenses onto a substrate, forming a thin Al/Cr film or coating tailored to desired characteristics.

1.Solar Cells: Al/Cr films serve as back contacts in solar cells, offering excellent electrical conductivity, adhesion, and stability, making them ideal for solar energy applications.

2.Optical Coatings: Al/Cr films are utilized as reflective coatings in optical systems, exhibiting high reflectivity across the UV to NIR spectrum, enhancing optical performance in mirrors and optical devices.

3.Automotive Reflectors: Al/Cr films are integral to automotive reflectors, providing superior reflectivity and substrate adhesion for efficient light reflection.

4.Microelectronics: Al/Cr films function as interconnects and protective coatings in microelectronics, delivering both electrical conductivity and corrosion resistance crucial for electronic devices.

5.Wear-resistant Coatings: Al/Cr films are employed as wear-resistant coatings in applications requiring high hardness and low friction, enhancing the longevity and performance of tools, molds, and components.

6.Semiconductor Devices: Al/Cr films play a pivotal role in semiconductor device manufacturing, serving as diffusion barriers, electrical contacts, and bonding layers in integrated circuits and electronic components.

Material: Chromium Cobalt Alloy

Purity: Cr 99.9% ~ 99.99%, Customized Compositions

Form: Pieces, Pellets, Powder

Size: 2*2mm, 3*3mm, 6*6mm, or Customized

Material: Chromium Nickle Alloy, Nichrome / Inconel

Purity: Cr 99.9% ~ 99.99%, Customized Compositions

Form: Pieces, Pellets, Powder

Size: 2*2mm, 3*3mm, 6*6mm, or Customized

Material: Iron Chromium Alloy, Ferrochrome

Purity: Cr 99.9% ~ 99.99%, Customized Compositions

Form: Pieces, Pellets, Powder

Size: 2*2mm, 3*3mm, 6*6mm, or Customized

Chromium Molybdenum Evaporation Material, Cr/Mo

Material: Chromium Vanadium Alloy

Purity: Cr 99.9%, Customized Compositions

Form: Pieces, Pellets, Powder

Size: 2*2mm, 3*3mm, 6*6mm, or Customized

Main Applications: Optical Coatings, Solar Cells, Electronics

Step up your thin-film deposition game with Vanadium Chromium (V/Cr) Evaporation Materials. Thanks to their synergistic composition of vanadium and chromium, these materials are optimized for exceptional thin-film performance. They are designed to meet the demanding requirements of cutting-edge thin-film applications, with features like high melting points, thermal stability, and versatility.

The combination of vanadium and chromium brings forth stable and durable materials during the thin-film deposition process, thanks to their elevated melting points. These materials also have exceptional thermal stability, which makes them ideal for applications subjected to high temperatures. Moreover, thanks to their adaptable properties, V/Cr materials are versatile and can be used in a broad spectrum of industries, from electronics to optics.

Material: Chromium Molybdenum Alloy

Purity: Cr 99.9% ~ 99.99%, Customized Compositions

Form: Pieces, Pellets, Powder

Size: 2*2mm, 3*3mm, 6*6mm, or Customized

Material: Cr/Ti, Ti/Cr, Co/Ni/Cr, Cu/Cr, Ni/Cr/Al, Ni/Cr/Si

Purity: Cr 99.9% ~ 99.99%, Customized Compositions

Form: Pieces, Pellets, Powder

Size: Can be Customized

Chromium is a hard, lustrous, blue-silvery white metal metal with high corrosion resistance. Due to its high corrosion resistance against many different acids and bases as well as hot gases, chromium is a popular material for all types of protective coating. It is commonly found in the Earth’s crust in the form of chromite ore and has various industrial applications, including as an essential component in the production of stainless steel and alloys used in aerospace, automotive, and construction industries. Chromium also plays an essential role in biological systems, but certain forms of it can be toxic and carcinogenic if ingested or inhaled in high concentrations. As a component in high-temperature fuel cells, chromium also performs brilliantly. Besides, chromium is often used as a brilliant decorative coating for operating elements on appliances or jewelry.

Material Type | Chromium | Z Ratio | 0.305 |

Symbol | Cr | E-Beam | Good |

Atomic Weight | 51.9961 | Thermal Evaporation Techniques | Boat: Cr Plated W Rods Coil: W Basket: W Crucible: VitC |

Atomic Number | 24 | ||

Color/Appearance | Silvery, Metallic | E-Beam Crucible Liner Material | FABMATE®, Graphite, Tungsten |

Thermal Conductivity | 94 W/m.K | Temp. (°C) for Given Vap. Press. (Torr)

| 10-8: 837 |

Melting Point | 1,857 °C | 10-6: 977 | |

10-4: 1,157 | |||

Coefficient of Thermal Expansion | 4.9 x 10-6/K | Comments | Films very adherent. High rates possible. |

Theoretical Density | 7.2 g/cc | Suggested QCM Crystal | Alloy Crystal: 750-1002-G10**** |

Our Chromium Evaporation Materials are clearly labeled externally to ensure efficient identification and quality control. To prevent any damage during storage or transportation, we take great care.