Menu

MetalsTek Engineering is a trusted manufacturer and supplier of TZM alloy, and its products. We are good at custom TZM products according to requests, with short lead times and factory-direct prices.

Size Range: Thick0.1~40mm * 50~600mm *100~1,500mm

Density: ≥10.1g/cm3

Tensile Strength: ≥830MPa

Yield Strength: ≥690MPa

Elongation: ≥10%

Hardness: HV240-280

Arc chamber parts in ion implanter, high-temperature furnace construction, die casting mold, and more.

Size Range: Diameter 15~100mm*200~1,500mm

Density: ≥10.05g/cm3

Tensile Strength: ≥735MPa

Yield Strength: ≥685MPa

Elongation: ≥10%

Hardness: HV240-280

Applications: Connector of the rotary X-ray sputtering targets, high-temperature molds, furnace construction, and more.

Material: TZM Alloy

Density: ≥10.05g/cm3

Tensile Strength: ≥735MPa

Yield Strength: ≥685MPa

Elongation: ≥10%

Hardness: HV240-280

Size Range: Tailored Diameters, Wall Thick 0.1~30mm, Length 5~6,000mm

Surface: Polished(Ra<3.2), Chemical Cleaned

TZM alloy, also known as TZM molybdenum alloy, is a titanium-zirconium-molybdenum alloy containing 0.50% titanium, 0.08% zirconium, and 0.02% carbon, with the balance being molybdenum. This alloy is manufactured using either powder metallurgy or arc-cast processes. TZM alloy has several advantages over pure molybdenum, including higher creep resistance, strength, and oxidation resistance. It is commonly used in high-temperature applications and tooling for hot die forging.

Main Components: Ti: 0.4-0.55%, Zr: 0.06-0.12%, C: 0.01-0.04%, Mo: Balance

| Others | O | Al | Fe | Mg | Ni | Si | N | Mo |

|---|---|---|---|---|---|---|---|---|

| Content (wt. %) | ≤0.03 | ≤0.01 | ≤0.002 | ≤0.002 | ≤0.002 | ≤0.002 | ≤0.002 | Bal. |

Physical Properties | Metric | English | Comments |

| Density | 10.16 g/cc | 0.3671 lb/in³ | |

Mechanical Properties | Metric | English | Comments |

| Tensile Strength, Ultimate | 83.0 MPa | 12000 psi | |

| @Temperature 1650 °C | @Temperature 3000 °F | ||

| 490 MPa | 71100 psi | ||

| @Temperature 1095 °C | @Temperature 2003 °F | ||

| 965 MPa | 140000 psi | ||

| @Temperature 23.0 °C | @Temperature 73.4 °F | ||

| Tensile Strength, Yield | 62.0 MPa | 8990 psi | |

| @Temperature 1650 °C | @Temperature 3000 °F | ||

| 435 MPa | 63100 psi | ||

| @Temperature 1095 °C | @Temperature 2003 °F | ||

| 860 MPa | 125000 psi | ||

| @Temperature 23.0 °C | @Temperature 73.4 °F | ||

| Elongation at Break | 10% | 10% | in 50 mm |

| Rupture Strength | 159 MPa | 23000 psi | Stress Relief Annealed |

| @Temperature 1320 °C, | @Temperature 2400 °F, | ||

| Time 36000 sec | Time 10.0 hour | ||

| Modulus of Elasticity | 325 GPa | 47100 ksi | Pure Molybdenum |

Thermal Properties | Metric | English | Comments |

| CTE, linear | 4.90 µm/m-°C | 2.72 µin/in-°F | |

| @Temperature 20.0 – 40.0 °C | @Temperature 68.0 – 104 °F | ||

| 5.90 µm/m-°C | 3.28 µin/in-°F | Estimated from Pure Mo. | |

| @Temperature 20.0 – 250 °C | @Temperature 68.0 – 482 °F | ||

| 6.00 µm/m-°C | 3.33 µin/in-°F | Estimated from Pure Mo. | |

| @Temperature 20.0 – 500 °C | @Temperature 68.0 – 932 °F | ||

| 6.10 µm/m-°C | 3.39 µin/in-°F | Estimated from Mo-0.5Ti | |

| @Temperature 20.0 – 1000 °C | @Temperature 68.0 – 1830 °F | ||

| Specific Heat Capacity | 0.250 J/g-°C | 0.0598 BTU/lb-°F | Estimated from Pure Mo. |

| Thermal Conductivity | 118 W/m-K | 819 BTU-in/hr-ft²-°F | |

| @Temperature 500 °C | @Temperature 932 °F | ||

| Melting Point | <= 2620 °C | <= 4750 °F | |

| Liquidus | 2620 °C | 4750 °F | |

Chemical Properties | Metric | English | Comments |

| Carbon, C | 0.010 – 0.040 % | 0.010 – 0.040 % | |

| Hydrogen, H | <= 0.00050 % | <= 0.00050 % | |

| Iron, Fe | <= 0.010 % | <= 0.010 % | |

| Molybdenum, Mo | 99.40% | 99.40% | |

| Nickel, Ni | <= 0.0050 % | <= 0.0050 % | |

| Nitrogen, N | <= 0.0020 % | <= 0.0020 % | |

| Oxygen, O | <= 0.030 % | <= 0.030 % | |

| Silicon, Si | <= 0.0050 % | <= 0.0050 % | |

| Titanium, Ti | 0.40 – 0.55 % | 0.40 – 0.55 % | |

| Zirconium, Zr | 0.060 – 0.12 % | 0.060 – 0.12 % |

TZM alloy is widely used in high-temperature applications and tooling for hot die forging, as well as in various industries such as vacuum furnace construction, medical diagnostic equipment, and more

Our TZM Alloy are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

In the realm of advanced materials critical to high-tech industries, TZM alloy stands out for its exceptional performance under extreme conditions. But what exactly is TZM, and why is it becoming increasingly crucial in applications ranging from aerospace to electronics? This article dives deep into the world of TZM alloy, shedding light on its composition, properties, and the pivotal role it plays in modern technology.

TZM alloy, short for Titanium-Zirconium-Molybdenum alloy, is a high-performance refractory metal alloy, an enhanced version of pure molybdenum, known for its exceptional properties at high temperatures. By incorporating small percentages of titanium and zirconium with a base of molybdenum, this alloy offers superior strength and resistance to high temperatures and corrosive environments.

The raw materials of TZM consist primarily of molybdenum (Mo), with about 0.5% titanium (Ti), 0.08% zirconium (Zr), and 0.02% carbon (C) added as carbide-forming elements. These additions give TZM better properties than pure molybdenum, making it a top choice for high-end engineering projects.

Element | Content (%) |

Molybdenum, Mo | 99.38-99.41 |

Titanium, Ti | 0.5 |

Zirconium, Zr | 0.08 |

Carbon, C | 0.010-0.040 |

The raw materials used in the production of TZM alloy are high-purity molybdenum powder, titanium hydride (TiH2) powder, zirconium hydride (ZrH2) powder, and graphite powder.

Preparation Methods of TZM Alloy The preparation of TZM alloy involves several sophisticated metallurgical processes designed to ensure optimal performance in its end use. These processes include:

These preparation methods are crucial for ensuring that TZM alloy delivers the expected performance in demanding applications, such as in aerospace and electronics, where standard materials might fail. The careful control of raw material quality, combined with precise manufacturing processes, defines the success of TZM alloy in critical applications.

TZM alloy exhibits a range of exceptional properties that make it suitable for various high-temperature applications:

Mechanical Properties

Thermal Properties

Electrical Properties

Corrosion Resistance: TZM offers better resistance to oxidation than pure molybdenum at temperatures up to 400°C. Beyond this, protective measures or coatings may be required to prevent oxidation in an air environment.

Creep Resistance: One of the primary advantages of TZM over pure molybdenum is its superior creep resistance at high temperatures. This makes TZM suitable for use in components like jet engine parts and high-temperature furnace components, where materials are subject to prolonged exposure to stress and high temperatures.

These properties ensure that TZM alloy remains a material of choice for engineers and designers seeking to overcome the limitations of traditional metals in extreme environments. Whether in aerospace, defense, or advanced manufacturing, TZM’s blend of high-temperature strength, thermal stability, and resistance to mechanical wear offers significant advantages, making it an essential component in the design of next-generation technologies.

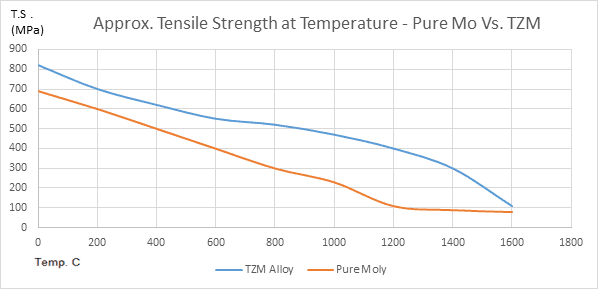

While both TZM alloy and pure molybdenum are refractory metals, there are several key differences between the two. These differences are not just in the chemical composition but extend to mechanical strength, thermal performance, and application suitability. Here’s a detailed comparison:

Composition

Mechanical Properties

Thermal Properties

Resistance to Oxidation

Applications

Cost and Processing

Processing: TZM can be more challenging to process than pure molybdenum due to its higher hardness and strength, which may require more advanced manufacturing techniques and tools.

TZM alloy, with its enhanced properties derived from the addition of titanium, zirconium, and carbon to its primary molybdenum base, is tailored for use in environments where high strength, excellent creep resistance, and superior thermal properties are crucial. The specialized applications of TZM alloy span various high-tech and industrial sectors, reflecting its ability to perform under extreme conditions. Here’s a detailed look at where TZM alloy is commonly used:

Aerospace and Aviation

Electronics and Electrical Industries

High-Temperature Industrial Applications

Medical Technology

Nuclear Energy

Research and Development

Coating Technology

The wide-ranging applications of TZM alloy illustrate its versatility and essential role in modern technology and industrial processes. Its enhanced material properties not only allow it to operate effectively in extreme conditions but also contribute to the advancement and reliability of technologies in sectors demanding the utmost performance. This adaptability and robustness ensure that TZM alloy remains a preferred material for engineers and designers tackling the challenges of today’s high-demand environments.

TZM alloy is a remarkable refractory metal alloy that combines the high-temperature strength of molybdenum with the added benefits of titanium, zirconium, and carbon. Its unique properties make it an ideal choice for various high-temperature applications, particularly in industries where performance and reliability are critical. As a leading supplier of molybdenum products, MetalsTek Engineering offers a wide range of TZM alloy products to meet the needs of researchers and manufacturers worldwide.