Menu

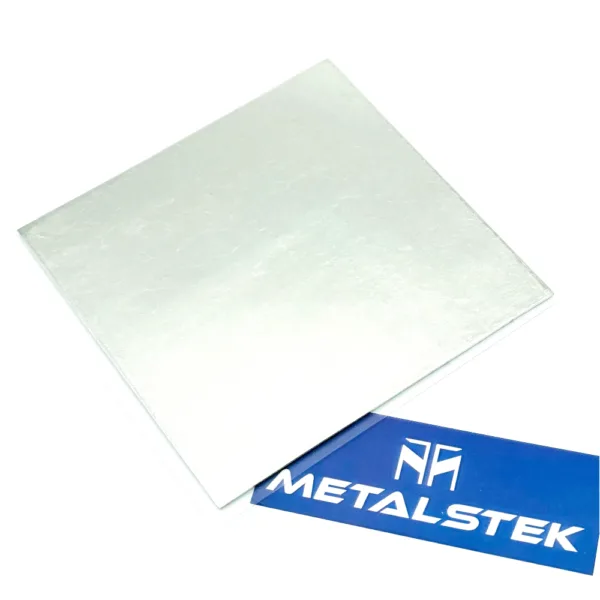

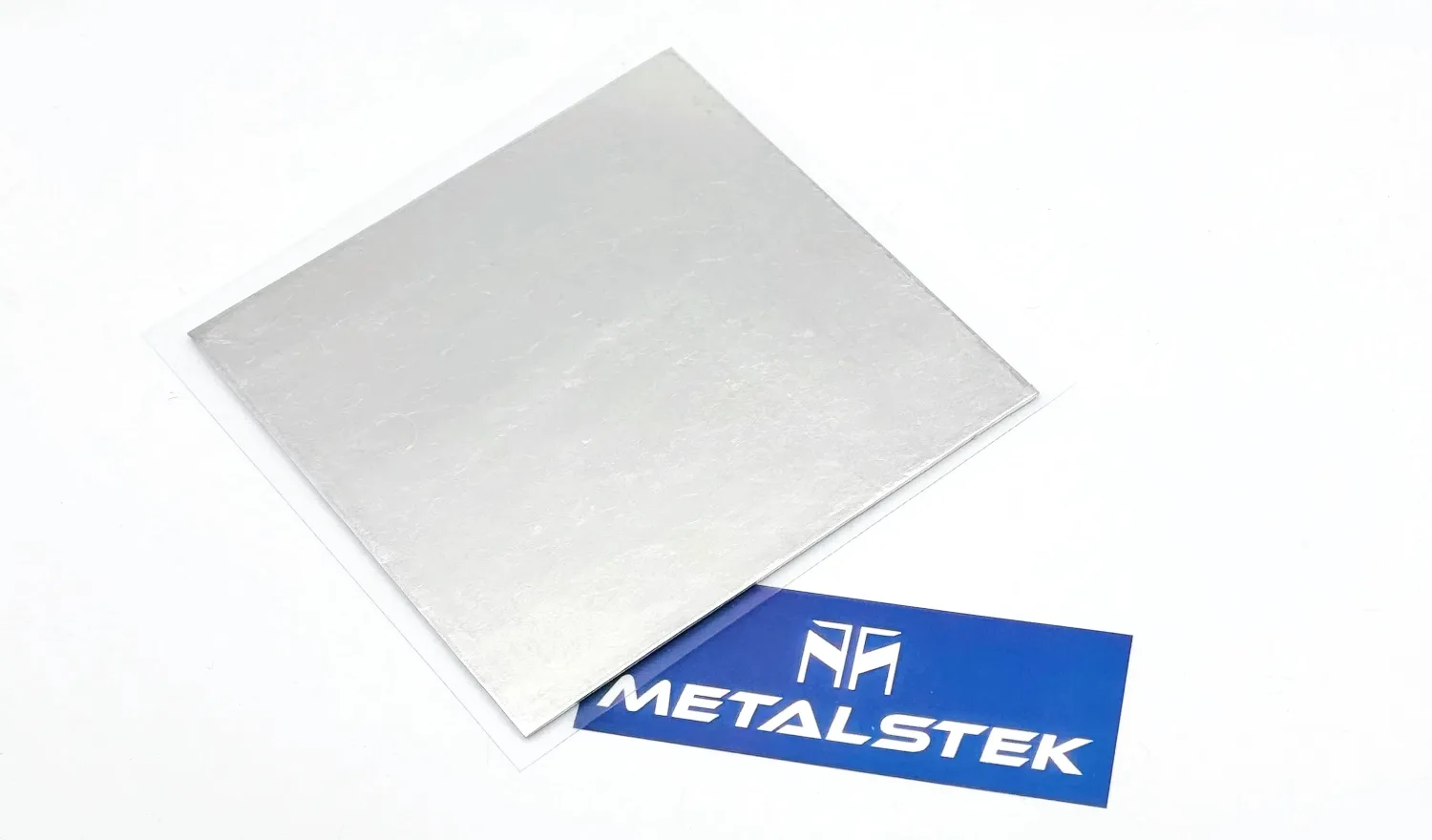

MetalsTek Engineering is a trusted indium foil, indium sheets, and discs supplier. Our newly acquired equipment can manufacture Indium as thin as 0.05mm. We can also produce custom Indium products, such as Indium Sputtering Targets, according to your needs.

Material: Indium, CAS # 7440-74-6

Purity: In 99.99%~99.999%

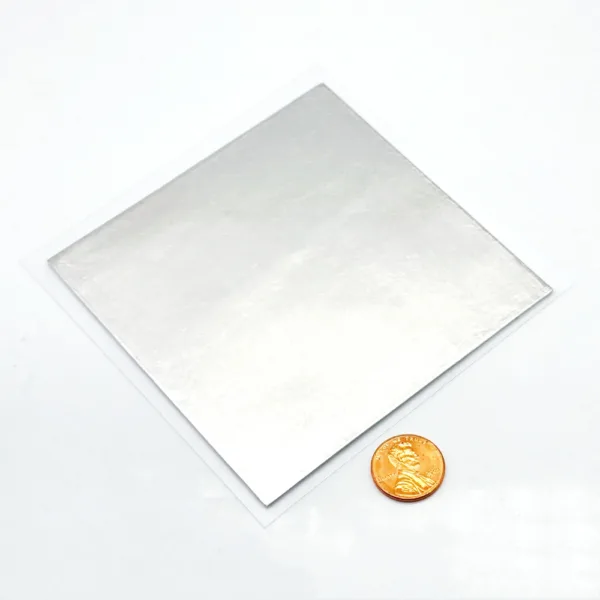

Properties: Silvery, 7.31g/cc Density, 156.6°C M.P.

Sizes: Thickness 0.05mm~2.00mm * Length * Width, Can be Customized

Other: Large Inventories

Indium foil sheet is a valuable material known for its efficient heat sink properties in high-temperature and cryogenic applications, and it is commonly used in the semiconductor industry for various purposes. Indium, discovered in 1863, is a soft and malleable element with a low toxicity level and a melting point of 157°C. Indium foil and sheet are effective heat sinks due to their flexibility even near zero, making them ideal for applications requiring precise thermal management. Additionally, Indium’s ability to adhere to glass surfaces makes it suitable for transparent conductive coatings to produce touchscreens and liquid crystal displays.

Due to its unique properties, Indium Sheet Foil finds diverse applications across various industries. Here are some typical applications:

1. Sealing and Hermetic Packaging: Indium sheet foil is widely used to create airtight seals in vacuum and gas-tight enclosures. It is also commonly used in the aerospace, automotive, and electronics industries to seal components such as sensors, connectors, and optical devices to protect them from environmental contaminants.

2. Thermal Interface Materials (TIMs): Indium sheet foil is used in electronic devices as a thermal interface material to facilitate efficient heat transfer between components. It is used in applications such as thermal management of CPUs, power electronics, and LED lighting systems to dissipate heat and prevent overheating.

3. Soldering and Brazing: Indium sheet foil is employed in soldering and brazing applications due to its low melting point and excellent wetting properties. It is often used in electronics assembly, semiconductor manufacturing, and joining delicate components where precise and reliable bonding is required.

4. Thin-Film Deposition: Indium sheet foil is used as a source material in thin-film deposition techniques such as thermal evaporation and sputtering. It is employed to deposit indium-based thin films onto substrates for electronics, optics, and photovoltaics applications, including producing transparent conductive coatings for touchscreens and solar cells.

5. Electrical Contacts: Indium sheet foil is utilized in electrical contacts and switches due to its excellent conductivity and resistance to oxidation. It is commonly used in applications requiring reliable and low-resistance electrical connections, such as automotive switches, relays, and high-frequency connectors.

6. Cryogenic Seals: Indium sheet foil is used in cryogenic systems to create seals and gaskets at low temperatures. It maintains flexibility and forms a tight seal even at extremely low temperatures, making it suitable for applications in cryogenic engineering, superconducting magnets, and aerospace.

7. Research and Development: Indium sheet foil is utilized in scientific research and development for various experimental and prototyping purposes. It is employed in laboratories to test, calibrate, and fabricate specialized equipment and devices across multiple disciplines.

Overall, indium sheet foil’s versatility, reliability, and unique properties make it an essential material in numerous industrial, electronic, and scientific applications, contributing to advancements in technology, manufacturing, and research.

Our Indium Sheets are well packed and clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.

Imagine a material so versatile and efficient that it is a cornerstone in advanced industries like electronics, aerospace, and semiconductors. Indium foil and sheets, with their exceptional thermal and electrical properties, are the unsung heroes in high-tech applications. But how do you ensure you’re sourcing the best indium products to meet your precise requirements? In this article, we explore the properties and applications of indium foil and sheets while guiding you on selecting the right supplier to optimize your business needs.

Indium foil and sheets are thin, malleable forms of indium metal, a rare and versatile element known for its unique combination of properties. While indium foil is typically thinner and more flexible, indium sheets are slightly thicker and often used in structural or supportive applications.

Standard thickness ranges from a few micrometers to several millimeters, and dimensions can be tailored to your needs. These products are prized for their ability to form seals, dissipate heat, and conduct electricity, making them essential in high-performance environments.

Indium foil and sheets are utilized across diverse industries. Here are some of their notable applications:

Indium stands out for its exceptional physical and chemical properties:

When compared to other materials like aluminum or copper, indium offers unmatched flexibility and compatibility with cutting-edge technologies.

Choosing the right supplier is critical to ensure the quality and performance of indium products. Here are factors to consider:

At MetalsTek, we pride ourselves on being a trusted supplier of high-purity indium foil and sheets. Here’s why we stand out:

Q1: What is the maximum thickness of indium sheets available?

A1: MetalsTek offers indium sheets in customizable thicknesses, typically ranging from a few micrometers to several millimeters.

Q2: How is the purity of indium measured?

A2: We ensure high purity through advanced analytical techniques like ICP-MS, meeting industry standards up to 99.999%.

Q3: Can MetalsTek provide custom shapes and sizes?

A3: Yes, we specialize in delivering customized indium products tailored to your specifications.