Menu

Compositions: ≈3% Aluminum and 1% Zinc

Features: Weldability and Good Strength

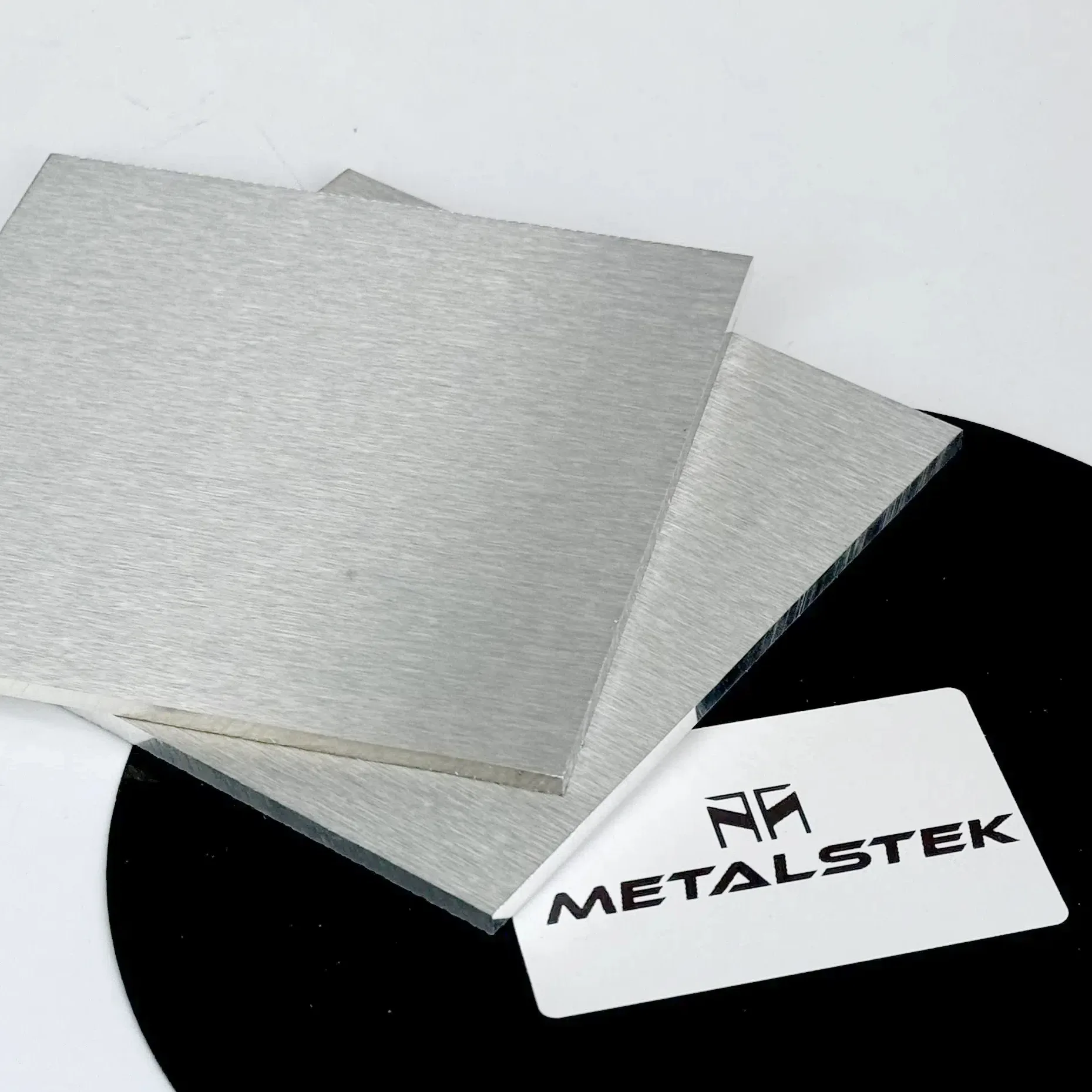

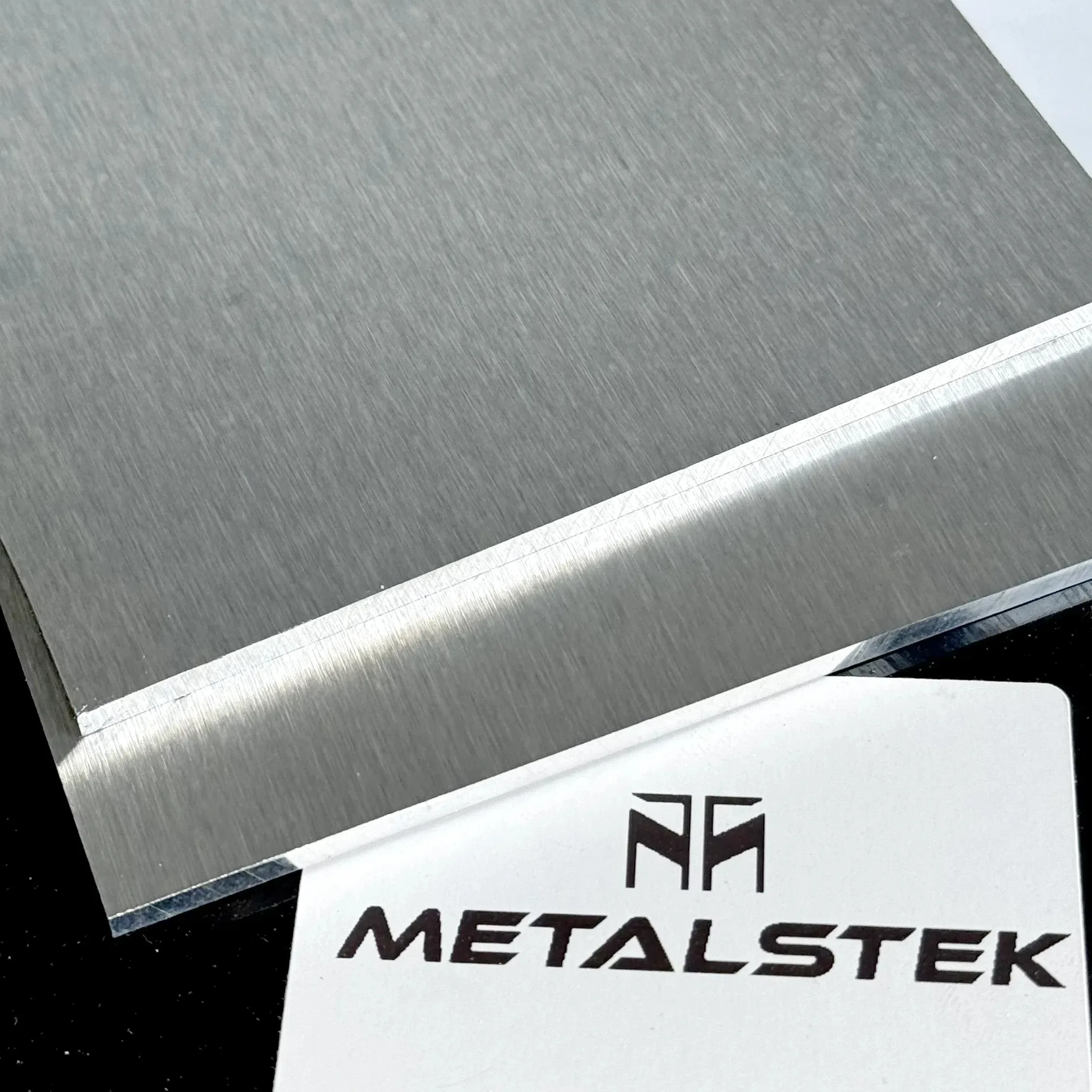

Shapes: Wire, Rod, Sheet, Plate, Bar, Tubes, Customized Shapes

Applications: Aerospace Applications, Automotive Parts, and Structural Components

Compositions: ≈6% Aluminum and 1% Zinc

Features: Higher Strength, ≈290MPa Tensile, 180MPa Yield; Ductility, Corrosion Resistance

Shapes: Wire, Rod, Sheet, Plate, Bar, Tubes, Customized Shapes

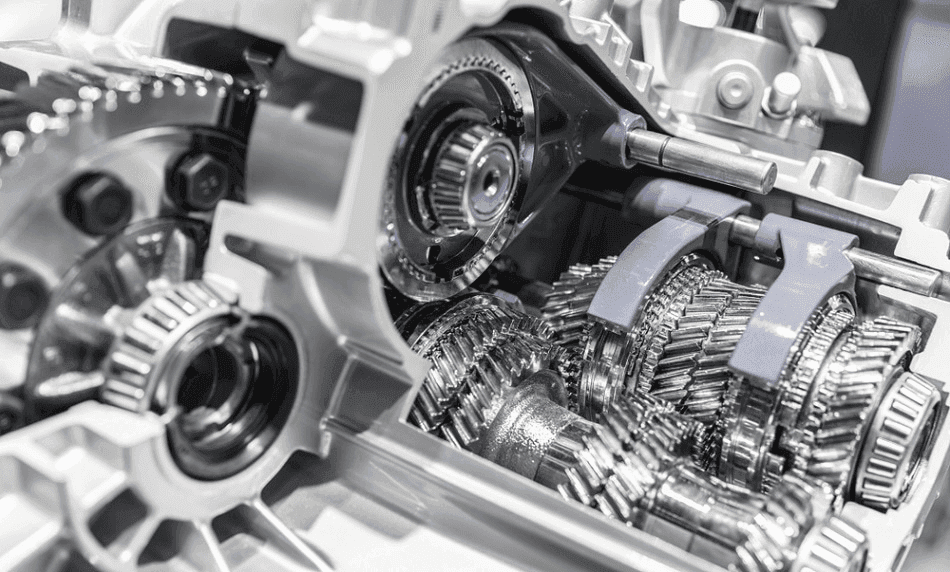

Applications: Aerospace, Automotive Parts(gearbox housing), Electronics(Laptop frames), Sporting Goods

Compositions: ≈9% Aluminum and 1% Zinc

Features: Corrosion Resistant, Weldability, Good Strength

Shapes: Wire, Rod, Sheet, Plate, Bar, Tubes, Customized Shapes

Applications: Commonly used in automotive industry such as transmission cases and engine blocks, electronics for heat dissipation

Compositions: ≈6% Aluminum and Manganese

Features: Excellent Balance Between Impact Strength and Ductility

Shapes: Wire, Rod, Sheet, Plate, Bar, Tubes, Customized Shapes

Applications: Automotive safety components such as steering wheels and seat frames

Model: ZK60, ZK61, ZK61M, MAZ61, MB15

Shapes: Wire, Rod, Sheet, Plate, Bar, Tubes, Customized Shapes

Size: Tailored Sizes

5083 (4.4-4.9% Mg, 0.4-1.0% Mn) – Used in shipbuilding, vehicles, and other applications requiring high strength and corrosion resistance.

5052 (2.2-2.8% Mg, 0.15-0.35% Cr) – Offers good formability, corrosion resistance, and weldability. Used in transportation, consumer goods, and architecture.

5754 (2.6-3.6% Mg) – A moderately strong alloy with good corrosion resistance, used in automotive and other transportation applications.

Magnesium aluminum alloys are part of a group of lightweight, high-performance materials extensively used across various industries due to their excellent strength-to-weight ratios. These alloys typically consist of magnesium, with aluminum being the primary alloying element, along with minor additions of zinc, manganese, and silicon to improve their properties.

Composition:

Properties:

Automotive Industry:

Aerospace Industry:

Consumer Electronics:

Sporting Goods:

Our Magnesium Aluminum Alloys are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.