Menu

MetalsTek Engineering is a worldwide leader in the manufacture and supply of high-purity Cobalt Evaporation Materials. We provide the following types of Cobalt Evaporation Materials: Co, Al/Co, Cr/Co, Co/Fe, Co/Ni/Cr, Co/Ni, Co/Ti, Co/W, Cu/Co, CoO, and LiCoO2.

Material: Cobalt

Purity: Co 99.9% ~ 99.99%

Properties: 8.9g/cc Density, 1,495°C M.P.

Thermal Conductivity: 100 W/m.K

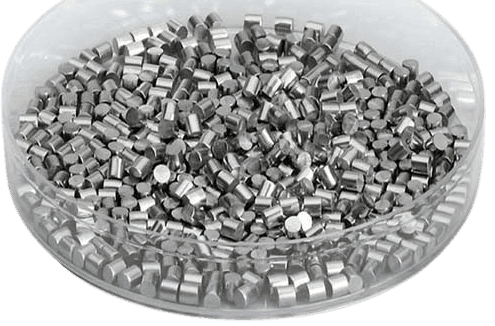

Form: Pieces, Pellets, Powder, or Customized

Size: Tailored Size

Material: Cobalt Oxide

Purity: CoO 99.9% ~ 99.99%

Properties: 6.45g/cc Density, 895°C M.P.

Form: Pieces, Pellets, Powder, or Customized

Size: Tailored Size

Material: Cobalt Aluminum

Purity: Co/Al or Al/Co, 99.9% ~ 99.95%

Form: Pieces, Pellets, Powder, or Customized

Size: Tailored Size

Cobalt aluminum (Co/Al) evaporation materials are utilized in vacuum deposition processes to create thin films of cobalt and aluminum on various substrates. These materials find applications in several industries:

1.Magnetic Recording Media: Co/Al thin films are commonly used in the production of magnetic recording media, such as hard disk drives (HDDs) and magnetic tapes. These films serve as the magnetic recording layer, contributing to the storage and retrieval of digital data.

2.Magnetic Sensors: Co/Al thin films are employed in the fabrication of magnetic sensors, such as giant magnetoresistance (GMR) and tunnel magnetoresistance (TMR) devices. These sensors are utilized in various applications, including magnetic field sensing, data storage, and magnetic read heads in HDDs.

3.Spintronics: Co/Al thin films play a role in spintronics, a field that explores the manipulation of electron spin for information storage and processing. These films are used in spintronic devices, such as spin valves and magnetic tunnel junctions (MTJs), for applications in non-volatile memory, magnetic random-access memory (MRAM), and magnetic sensors.

4.Microelectronics: Co/Al thin films are employed in microelectronics for various applications, including interconnects, barrier layers, and ohmic contacts. These films contribute to the performance and reliability of electronic devices such as integrated circuits (ICs), semiconductor devices, and microelectromechanical systems (MEMS).

5.Catalysis: Co/Al thin films are used as catalysts in chemical reactions, particularly in heterogeneous catalysis. These films can be deposited onto substrates to facilitate specific chemical transformations, such as hydrogenation, oxidation, and organic synthesis.

6.Optical Coatings: Co/Al thin films are utilized in optical coatings for applications such as anti-reflective coatings, protective layers, and optical filters. These coatings modify the optical properties of surfaces, including reflectance, transmittance, and absorption, for optical devices and components.

7.Research and Development: Co/Al evaporation materials are employed in research laboratories and academic institutions for thin film deposition experiments, material characterization studies, and the development of novel materials and devices.

Material: Chromium Cobalt

Purity: Co/Cr or Cr/Co, 99.9% ~ 99.99%

Form: Pieces, Pellets, Powder, or Customized

Size: Tailored Size

Material: Iron Cobalt

Purity: Co/Fe, 99.9% ~ 99.95%

Form: Pieces, Pellets, Powder, or Customized

Size: Tailored Size

Material: Cobalt Nickel

Purity: Co/Ni, 99.9% ~ 99.99%

Form: Pieces, Pellets, Powder, or Customized

Size: Tailored Size

Material: Copper Cobalt

Purity: Cu/Co, 99.9% ~ 99.99%

Form: Pieces, Pellets, Powder, or Customized

Size: Tailored Size

Material: Cobalt Titanium

Purity: Co/Ti, 99.9% ~ 99.99%

Form: Pieces, Pellets, Powder, or Customized

Size: Tailored Size

Material: Cobalt Tungsten

Purity: Cu/W, 99.9% ~ 99.95%

Form: Pieces, Pellets, Powder, or Customized

Size: Tailored Size

Material: Cobalt Nickel Chromium

Purity: Co/Ni/Cr, 99.9% ~ 99.95%

Form: Pieces, Pellets, Powder, or Customized

Size: Tailored Size

Cobalt is frequently employed in the form of evaporation materials across a range of applications. It is used in thermal evaporation processes to produce thin films and intricate hierarchical structures for diverse purposes. These materials, available in forms such as pellets, granules, or rods, are utilized in vacuum deposition processes, including semiconductor deposition, chemical vapor deposition (CVD) and physical vapor deposition (PVD), and optics, including wear protection, decorative coatings, and displays, to create thin cobalt films on various substrates.

Material Type | Cobalt † | Ferromagnetic | Magnetic Material |

Symbol | Co | Z Ratio | 0.343 |

Atomic Weight | 58.933195 | E-Beam | Excellent |

Atomic Number | 27 | Thermal Evaporation Techniques | Boat: W, Nb Basket: W Crucible: Al2O3 |

Color/Appearance | Lustrous, Metallic, Grayish Tinge | ||

Thermal Conductivity | 100 W/m.K | E-Beam Crucible Liner Material | Direct in Hearth |

Melting Point | 1,495 °C | Temp. (°C) for Given Vap. Press. (Torr) | 10-8: 850 |

Coefficient of Thermal Expansion | 13.0 x 10-6/K | 10-6: 990 | |

10-4: 1,200 | |||

Theoretical Density | 8.9 g/cc | Comments | Alloys with W/Ta/Mo. |

Suggested QCM Crystal | Silver Crystal: 750-1001-G10**** |

Cobalt and cobalt alloy evaporation materials are used in various deposition processes, including semiconductor deposition, chemical vapor deposition (CVD), and physical vapor deposition (PVD). These materials find applications in optics, such as for wear protection, decorative coatings, and displays. They are also utilized in various industries, including aerospace, automotive, electronics, and energy storage. Additionally, cobalt evaporation materials are essential for thin film research, thermal evaporation, and electron microscopy coatings. The high purity of these materials is critical for their effectiveness in various industrial and scientific applications.

Our Cobalt Evaporation Materials are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent damage during storage or transportation.