Menu

MetalsTek Engineering is a trusted supplier of Niobium Alloys. With over ten years of expertise, we can serve you with quality products and competitive prices.

Material: Nb56Ti44, Nb42Ti58

Purity: Nb56Ti44-99%, Nb42Ti58-99.9%

Form: Spherical Powder, Rod, Sheet, Tube, Wire, or Customized

Powder Size: Nb56Ti44 – 0~45μm, 45~105μm, or Customized

Nb42Ti58 – 10~63μm, 63~105μm, or Customized

Description: Niobium Titanium Alloy Powder is a binary alloy containing both Nb and Ti. The nearly equal percentage of Nb and Ti contributes distinct properties from both elements. Nb, a refractory metal, imparts high-temperature stability and corrosion resistance. Ti acts as a solid solution strengthener, enhancing metal cohesion, increasing strength, and boosting alloy hardness. Known for its biocompatibility and low density, Ti further enhances the alloy’s overall characteristics. Niobium Titanium Alloy Powder showcases outstanding mechanical properties, including high strength and corrosion resistance.

Applications:

Material: Nb63Ni-A, Nb63Ni-B, Nb56Ni-A, Nb56Ni-B

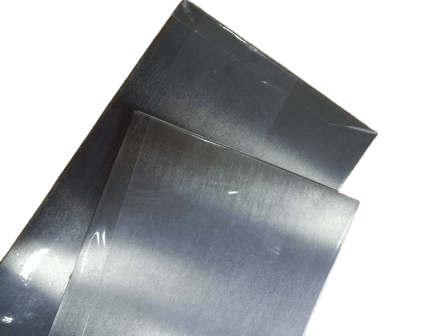

Form: Chunks, Foil, Sheet, Plate, or Customized

Size: Foil – Thick 0.03-0.20mm; Width <250 mm

Sheet/Plate – Thick <0.20 mm; Width <1,000mm

| Grade | Nb63Ni-A | Nb63Ni-B | Nb56Ni-A | Nb56Ni-B |

|---|---|---|---|---|

| Nb | ≥63.0 | ≥61.0 | ≥56.0 | ≥54.0 |

| Ni | Remainder | Remainder | Remainder | Remainder |

| Impurity Concentrations (%,≤) | ||||

| O | 0.1 | 0.2 | 0.1 | 0.2 |

| C | 0.05 | 0.1 | 0.05 | 0.1 |

| N | 0.05 | 0.08 | 0.05 | 0.08 |

| Fe | 0.5 | 0.5 | 0.5 | 0.5 |

| Si | 0.25 | 0.3 | 0.25 | 0.3 |

| Pb | 0.005 | 0.01 | 0.005 | 0.01 |

| Ta | 0.2 | 0.2 | 0.2 | 0.2 |

| Ti | 0.1 | 0.1 | 0.1 | 0.1 |

| Sn | 0.005 | 0.02 | 0.005 | 0.02 |

| S | 0.01 | 0.02 | 0.01 | 0.02 |

| Al | 1.5 | 2 | 1.5 | 2 |

| P | 0.01 | 0.03 | 0.01 | 0.03 |

Composition: 90Mo10Nb, 95Mo5Nb

Density: 9.2~9.4 g/cc

Shape: Ingot

Features: Improved high-temperature strength and creep resistance.

Application: Flat Panel Display (FPD), Semiconductor, Aviation Aerospace, Nuclear

Purity: 99.5% Min

Average Particle Size: 10~60um

Carbon (%): 6.12~6.22

Oxygen (%): 0.40% Max

Fluidity: 16 s/50g

Applications: Powder Metallurgy, Cutting Tools, Fine Ceramics, CVD, etc

| C | O | N | H | Hf | Ti | Zr | W | Ta |

|---|---|---|---|---|---|---|---|---|

| 0.015 | 0.025 | 0.01 | 0.002 | 9~11 | 0.7 – 1.3 | 0.7 | 0.5 | 0.5 |

| Density | 8.85 g/cm³ |

|---|---|

| Temperature | 2,349 ℃ |

| Coefficient of Line-expansion/10-6K-1 | 4.5 (1,203℃) |

| Recrystallization Temperature | 1,038℃ – 1,316℃ |

| Anneal Temperature | 871 ℃ |

Applications: Niobium Alloy C-103 proves to be a superb material for liquid rocket thruster nozzles, lightweight propulsion systems, and thrust chambers for rocket engines within the aerospace sector. This alloy is also employed in creating high-temperature jet engine parts and turbopumps, making it an ideal material for applications in space engineering fabrication.

Composition: Nb 60%~70%

Form: Powder, Granules

Size: Powder 60Mesh~325Mesh (45μm ~250μm)

Features: Main Source of HSLA Steel, Covers over 80% Niobium Production

Applications

| Nb (%) | Ta (%) | Si (%) | Al (%) | P (%) | C (%) | S (%) | Fe (%) |

|---|---|---|---|---|---|---|---|

| 60-70 | 0.1 | 0.7 | 1.7 | 0.025 | 0.025 | 0.03 | Balance |

Composition: Ti-30Al-10Nb, Ti-6Al-7Nb

Purity: 99.9%

Form: Spherical Powder, Ingot, Semi-finished

Powder Size: 0~45μm, 45~105μm, or Customized

Usage: Hardeners, Modifiers, Grain Refiners

| Grade | Balance | Nb | Si | Fe | C | O |

|---|---|---|---|---|---|---|

| AlNb50 | Al | 45.0~55.0 | 0.2 | 0.2 | 0.1 | 0.08 |

| AlNb60 | Al | 55.0~65.0 | 0.2 | 0.2 | 0.1 | 0.08 |

| AlNb65 | Al | 60.0~70.0 | 0.2 | 0.2 | 0.1 | 0.08 |

| AlNb70 | Al | 65.0~75.0 | 0.18 | 0.18 | 0.15 | 0.1 |

| AlNb80 | Al | 75.0~85.0 | 0.18 | 0.15 | 0.15 | 0.1 |

| Other Alloys | AlMn, AlTi, AlNi, AlV, AlSr, AlZr, AlCa, AlLi, AlFe, AlCu, AlCr, AlB, AlRe, AlBe, AlBi, AlCo, AlMo, AlW, AlMg, AlZn, AlSn, AlCe, AlY, AlLa, AlPr, AlNd, AlYb, AlSc, etc. | |||||

Niobium alloys are metallic alloys that contain niobium as one of the primary elements, along with other metals. These alloys are designed to harness the unique properties of niobium for various applications across different industries. Out of the Niobium Hafnium Alloy, Tantalum Niobium Alloy, and Niobium Zirconium Alloy, there are a few other Niobium Alloys that are widely used. They are Niobium Titanium Alloy, Niobium Nickel Alloy, Molybdenum Niobium Alloy, Niobium C-103 Alloy, Ferro Niobium (FeNb) Alloy, and Aluminum Niobium Master Alloy,.

Niobium Alloys find diverse applications across various industries due to their unique combination of properties. Here are some key applications of Niobium Alloys:

Our Niobium Alloy products are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Niobium Titanium, a remarkable alloy, has emerged as a game-changing material in various industries. This cutting-edge superconductor offers a multitude of uses and advantages over traditional titanium. From healthcare to aerospace, Niobium Titanium is revolutionizing the way we design and build.

One of the key advantages of Niobium Titanium is its exceptional conductivity, making it an ideal material for high-performance electronics and superconducting magnets. Its remarkable superconducting properties allow for enhanced energy efficiency and higher power transmission. Moreover, this alloy is highly resistant to corrosion, making it an excellent choice for applications requiring durability and longevity.

In this article, we delve deep into the world of Niobium Titanium, exploring its diverse applications across industries, its superior properties compared to titanium, and the wonders of the Niobium Titanium superconductor. Whether you’re a scientist, engineer, or simply curious about cutting-edge materials, join us as we unlock the power and potential of Niobium Titanium.

Niobium Titanium (NbTi) is a remarkable alloy that exhibits exceptional superconducting properties, making it a highly sought-after material in various industries. The superconducting behavior of NbTi is a result of its unique atomic structure and the interactions between the niobium and titanium elements.

At the heart of NbTi’s superconductivity lies its ability to conduct electricity with zero resistance at cryogenic temperatures. This phenomenon is known as superconductivity, and it occurs when the material is cooled below a critical temperature, typically around 9.2 Kelvin (K) for NbTi. At these low temperatures, the electrons in the material form Cooper pairs, which are able to flow through the material without encountering any resistance, resulting in the efficient and lossless transmission of electrical current.

The superconducting properties of NbTi are further enhanced by its ability to generate and maintain strong magnetic fields. When a superconducting material is placed in a magnetic field, it will expel the field from its interior, a phenomenon known as the Meissner effect. This property allows NbTi to be used in the creation of powerful superconducting magnets, which are essential for various applications, such as magnetic resonance imaging (MRI) machines, particle accelerators, and fusion energy research.

Niobium Titanium offers several distinct advantages over traditional titanium, making it a superior choice for a wide range of applications. One of the primary advantages of NbTi is its exceptional strength-to-weight ratio. Compared to titanium, NbTi is significantly lighter while maintaining exceptional strength and durability, making it an ideal material for use in aerospace, transportation, and other industries where weight is a critical factor.

Another key advantage of NbTi is its superior corrosion resistance. Titanium is known for its excellent corrosion resistance, but NbTi takes this property to an even higher level. The alloy’s unique composition and microstructure make it highly resistant to a wide range of corrosive environments, including seawater, acids, and harsh chemicals. This makes NbTi an excellent choice for applications where long-term durability and resistance to corrosion are essential, such as in marine environments, chemical processing plants, and medical implants.

Furthermore, NbTi exhibits exceptional thermal stability, allowing it to maintain its structural integrity and performance even under extreme temperature conditions. This property is particularly valuable in applications such as cryogenic systems, where materials must be able to withstand the challenges of low-temperature environments. Additionally, NbTi’s thermal conductivity is superior to that of titanium, making it a more efficient heat transfer material for various industrial and engineering applications.

Niobium Titanium’s unique properties have led to its widespread adoption across a diverse range of industries, each capitalizing on the material’s distinct advantages. One of the most prominent applications of NbTi is in the healthcare sector, where it is used extensively in the production of magnetic resonance imaging (MRI) machines. The superconducting properties of NbTi allow for the creation of powerful, high-field magnets that are essential for the operation of MRI systems, enabling detailed imaging of the human body and aiding in the diagnosis and treatment of various medical conditions.

In the aerospace industry, NbTi’s exceptional strength-to-weight ratio and corrosion resistance make it an ideal choice for a variety of components, including landing gear, engine parts, and structural components. The lightweight nature of NbTi helps to improve fuel efficiency and reduce overall aircraft weight, while its durability ensures the safety and reliability of these critical components.

The energy sector has also embraced the potential of NbTi, particularly in the field of nuclear fusion research. Superconducting magnets made from NbTi are essential for the containment and control of the high-temperature plasma required for fusion reactors, which hold the promise of providing a clean and sustainable source of energy. Additionally, NbTi is used in the construction of particle accelerators, which are crucial tools for scientific research and the development of new technologies.

The superconducting properties of Niobium Titanium are truly remarkable and have opened up a world of possibilities in various fields. One of the most fascinating aspects of NbTi superconductors is their ability to generate and maintain extremely strong magnetic fields, which are essential for a wide range of applications.

In the field of medical imaging, NbTi superconductors are the backbone of MRI technology, enabling the creation of powerful magnetic fields that can produce detailed, high-resolution images of the human body. These superconducting magnets are capable of generating fields up to 3.0 Tesla (T), which is significantly stronger than the Earth’s magnetic field and allows for the precise visualization of anatomical structures and the detection of various medical conditions.

Beyond medical applications, NbTi superconductors also play a crucial role in the development of fusion energy technology. In experimental fusion reactors, such as the International Thermonuclear Experimental Reactor (ITER), NbTi superconducting magnets are used to confine and control the high-temperature plasma required for the fusion process. These magnets are capable of generating magnetic fields in excess of 10 T, which is essential for the successful operation of these cutting-edge energy systems.

Niobium Titanium’s exceptional superconducting properties have also made it an invaluable material in the development of renewable energy technologies. One of the most promising applications of NbTi is in the field of superconducting wind turbines, where the material’s ability to generate and maintain strong magnetic fields is utilized to improve the efficiency and performance of these clean energy generators.

In a conventional wind turbine, the generator relies on copper windings to produce the necessary magnetic fields. However, these copper-based systems suffer from energy losses due to the inherent resistance of the copper. By replacing the copper windings with NbTi superconducting coils, the efficiency of the generator can be significantly improved, as the superconducting material allows for the transmission of electrical current with virtually no resistance, resulting in reduced energy losses and increased power output.

Furthermore, the use of NbTi superconductors in wind turbines can lead to the development of larger and more powerful generators, as the superconducting coils can generate stronger magnetic fields while occupying a smaller physical footprint. This, in turn, allows for the construction of taller and more efficient wind turbines, capable of harnessing greater wind energy and contributing to the global transition towards renewable and sustainable energy sources.

While Niobium Titanium has undoubtedly revolutionized various industries, there are still ongoing challenges and areas for further research and development. One of the primary challenges is the need to improve the critical current density of NbTi superconductors, which determines the maximum current that can be carried without losing superconductivity.

Researchers are actively exploring ways to enhance the critical current density of NbTi, such as through the development of new manufacturing techniques, the optimization of material composition, and the incorporation of additional alloying elements. By increasing the critical current density, NbTi superconductors can be used in applications that require the transmission of even higher levels of electrical current, further expanding their versatility and impact.

Another area of focus in NbTi research is the development of more cost-effective and scalable production methods. Currently, the manufacturing process for NbTi can be relatively complex and expensive, which can limit its widespread adoption in certain industries. Scientists and engineers are working to streamline the production techniques, explore alternative manufacturing approaches, and find ways to reduce the overall cost of NbTi, making it more accessible and competitive with other materials.

While Niobium Titanium is a remarkable superconducting material, it is not the only player in the field of superconductivity. Other superconducting materials, such as Niobium Tin (Nb3Sn) and High-Temperature Superconductors (HTS), offer unique properties and capabilities that make them suitable for different applications.

Niobium Tin, for example, is known for its ability to generate even stronger magnetic fields than NbTi, making it a preferred choice for applications that require the highest possible field strengths, such as in particle accelerators and fusion energy research. However, Nb3Sn is generally more brittle and challenging to manufacture than NbTi, which can limit its suitability for certain applications.

High-Temperature Superconductors, on the other hand, offer the advantage of operating at higher temperatures compared to NbTi and Nb3Sn, which typically require cryogenic cooling systems. HTS materials, such as Yttrium Barium Copper Oxide (YBCO) and Bismuth Strontium Calcium Copper Oxide (BSCCO), can function as superconductors at temperatures up to 77 K, which can be achieved using more affordable and readily available liquid nitrogen. This property makes HTS materials attractive for applications where the cost and complexity of cryogenic systems need to be minimized.

Niobium Titanium is a commercially available material, with a global market that has been steadily growing in recent years. The primary producers of NbTi are located in a few key regions, including the United States, Europe, and Asia, where specialized manufacturers have developed the expertise and infrastructure to produce high-quality NbTi alloys and superconducting components.

While the cost of NbTi can be higher than that of traditional titanium, the material’s exceptional properties and performance often justify the investment. The unique superconducting capabilities of NbTi, as well as its superior strength-to-weight ratio and corrosion resistance, make it a valuable material for a wide range of applications, from healthcare to renewable energy. As the demand for advanced materials continues to grow, the commercial availability and cost-effectiveness of NbTi are expected to improve, further driving its adoption across various industries.

It is worth noting that the cost of NbTi can vary depending on factors such as the purity of the raw materials, the complexity of the manufacturing process, and the specific application requirements. Additionally, the development of more efficient and scalable production methods, as well as the potential for increased competition in the market, may contribute to a more favorable cost-benefit ratio for NbTi in the future.

Niobium Titanium is a remarkable material that has the potential to revolutionize a wide range of industries and technologies. Its exceptional superconducting properties, combined with its superior strength, lightweight, and corrosion resistance, make it an invaluable asset in fields as diverse as healthcare, aerospace, energy, and beyond.

From the powerful superconducting magnets used in MRI machines to the cutting-edge fusion energy research, Niobium Titanium has consistently demonstrated its ability to push the boundaries of what is possible. As the world continues to seek more efficient, sustainable, and high-performance solutions, the role of NbTi will only continue to grow, unlocking new opportunities and transforming the way we approach technological challenges.

The future of Niobium Titanium is filled with exciting possibilities. As researchers and engineers continue to explore new applications and refine the material’s properties, we can expect to see even more remarkable advancements in the years to come. Whether it’s in the realm of renewable energy, medical diagnostics, or cutting-edge scientific research, Niobium Titanium stands as a testament to the power of innovation and the transformative potential of advanced materials.

At MetalsTek, we take great pride in providing top-notch Niobium Titanium Alloys that meet the demanding requirements of today’s industries. Our dedication to quality, coupled with our capability to tailor targets to precise sizes and compositions, positions us as the go-to choice for businesses looking to push boundaries and achieve greatness.