Menu

MetalsTek Engineering can provide quality Silver Alloys with different materials and compositions, tailored for your specific applications.

Tungsten-based composites are robust refractory metal materials that are manufactured using a strictly controlled process, which includes pressing, sintering, and infiltrating with copper or silver. The properties of tungsten composites depend on the copper/silver-to-tungsten ratio. As the tungsten content increases, the electric arc and wear resistance of the composite also increase. However, the thermal and electrical conductivity of the composite decrease as a result.

The main applications include:

– As electrical contacts or heat sinks in electric resistance welding.

– In electrodes for electrical discharge machining (EDM) and electrochemical machining (ECM).

| Composition | Nominal Composition | Density | Electrical Resistivity | Electrical Conductivity | Hardness | Bending Strength |

| (% Weight) | (g/cm3) | (20°C, µΩ•cm) | (IACS%, ≥) | (HB, ≥) | ( MPa ) | |

| AgW50 | 50 Silver | 13.15 | 3 | 57 | 105 | — |

| 50 Tungsten | ||||||

| AgW55 | 45 Silver | 13.55 | 3.2 | 54 | 115 | — |

| 55 Tungsten | ||||||

| AgW60 | 40 Silver | 14 | 3.4 | 51 | 125 | — |

| 60 Tungsten | ||||||

| AgW65 | 35 Silver | 14.5 | 3.6 | 48 | 135 | — |

| 65 Tungsten | ||||||

| AgW70 | 30 Silver | 14.9 | 3.8 | 45 | 150 | 657 |

| 70 Tungsten | ||||||

| AgW75 | 25 Silver | 15.4 | 4.2 | 41 | 165 | 686 |

| 75Tungsten | ||||||

| AgW80 | 20 Silver | 16.1 | 4.6 | 37 | 180 | 726 |

| 80 Tungsten |

Material: Silver Copper

Purity: 99.99%, Composition Customized

APS: 20nm~100nm, or Customized

Morphology: Nearly Spherical

Applications: Conductive Adhesive, Conductive Pain, Rubber, Plastic, Plymer Slurry, Conductive Electrostatic Paint, etc

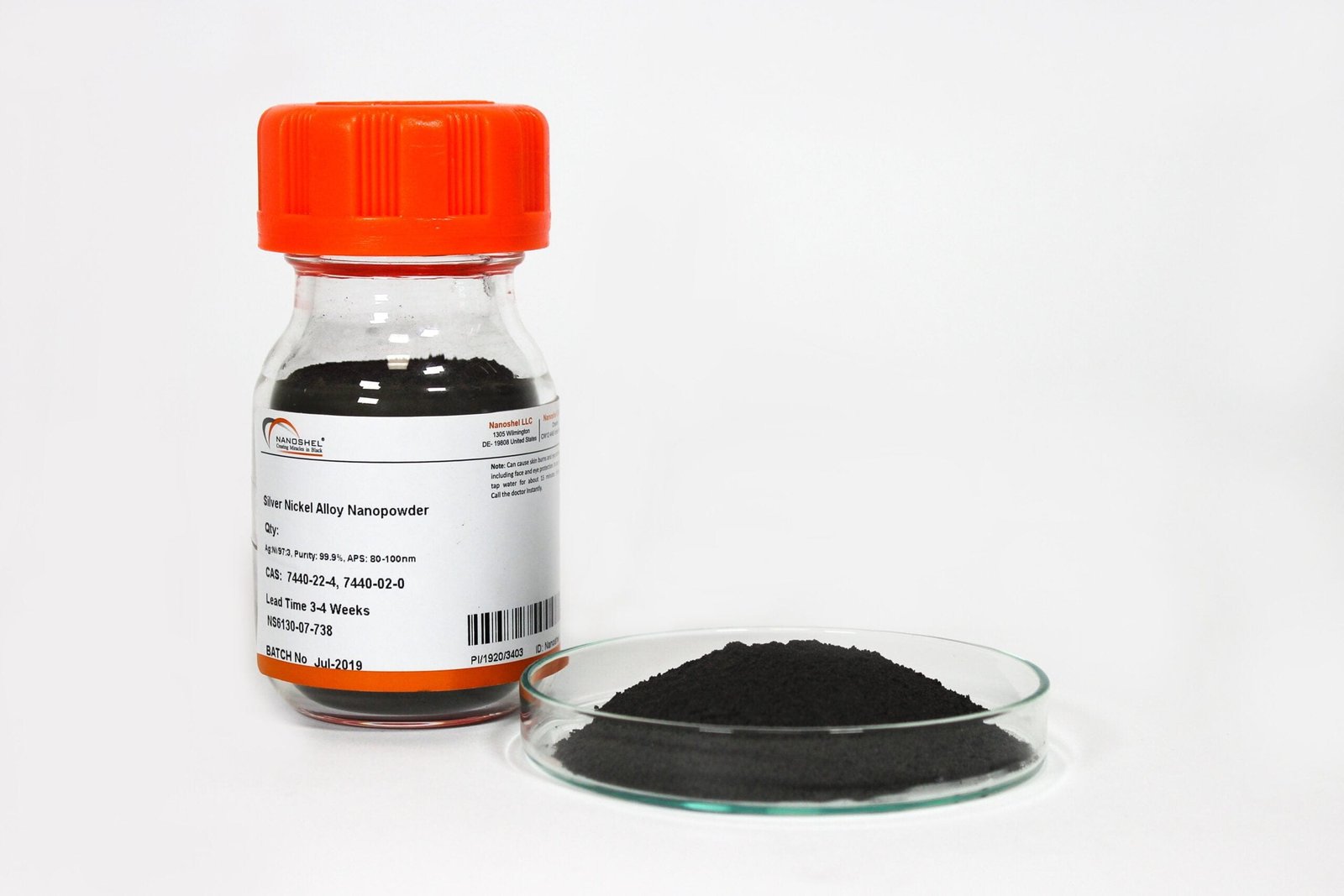

Material: Silver Nickel

Purity: 99.9%, Ag97Ni3

APS: 20nm~100nm, or Customized

Morphology: Nearly Spherical

Applications: Electronics, Aerospace

Material: Lead Silver

Compositions: Customized

Melting Point: 304℃

Form: Bar, Wire

Size: Tailored Size

Silver alloys are essential in various industries due to their unique properties and applications. There are several common types of silver alloys, including silver-copper alloy, tungsten silver alloy, silver-tin alloy, aluminum silver alloy, and silver nickel alloy. With different compositions, these alloys have different properties. For instance, Sterling Silver is an alloy consisting of 92.5% silver and 7.5% copper. It offers a balance between durability and malleability, with a hardness of 71 HV in the annealed state, which can be increased to 140 HV through strain hardening. Another notable alloy is Argenteum Sterling Silver, which includes germanium to enhance tarnish resistance and durability, making it suitable for everyday wear.

In industrial applications, Silver Brazing Alloys are popular for brazing various metals like copper, nickel, stainless steels, and carbon steels due to their high electrical conductivity and corrosion resistance. These brazing alloys typically contain silver, copper (20-50%), zinc (10-40%), and sometimes tin (2-5%) or silicon (0.1-0.25%) for improved flowability and appearance. Tungsten silver, another notable alloy, combines silver’s excellent conductivity with tungsten’s high melting point and hardness, creating materials ideal for electrical contacts and high-temperature applications.

Silver Alloys find wide-ranging applications across various industries due to their unique combination of properties, including conductivity, malleability, corrosion resistance, and aesthetic appeal. Some notable applications of Silver Alloys include:

These diverse applications highlight the versatility and importance of Silver Alloys in modern society, where their unique properties contribute to advancements in technology, healthcare, manufacturing, and everyday living.

We take great care when handling our silver powders to prevent any potential damage during storage or transportation. Through this careful approach, we ensure that our products maintain their original quality and integrity throughout the entire process, which keeps them in their pristine condition for optimal performance upon their arrival.