Menu

MetalsTek Engineering has over a decade of experience providing high-quality Iridium Crucibles at competitive prices. Our adept team excels in customizing this product to meet your specific requirements, ensuring a tailored solution that perfectly aligns with your needs.

Material: Iridium CAS# 7439-88-5

Purity: Ir>99.9%

Shapes: Cylindrical or Conical, Welded or Seamless

Size: Customized Sizes and Wall Thicknesses

Other: Refining and Supply New Crucibles with Short Lead Times

Iridium crucibles are specialized vessels for high-temperature applications, particularly metallurgy, single crystal growth, materials science, and semiconductor manufacturing. They are made from iridium, a rare and precious metal known for its exceptional properties. Iridium is the second-densest naturally occurring element, with a 22.56 g/cm³ density. It is extremely hard, brittle, and corrosion-resistant and has remarkable thermal and chemical stability, even at very high temperatures, up to 2,000°C.

Iridium crucibles are typically used for melting and holding materials at elevated temperatures in environments where other materials may degrade or react unfavorably. Due to their superior properties, iridium crucibles are ideal for handling reactive metals, alloys, and compounds that require precise control over temperature and purity during processing. Typical applications of iridium crucibles in research and development settings include crystal growth, thermal evaporation, chemical vapor deposition (CVD), and high-temperature experimentation.

| Rh | 42 | Au | 3 | Zr | 2 |

| Pd | 22 | Cr | 3 | B | <2 |

| Zn | 21 | Ni | 3 | Cd | <2 |

| Pt | 18 | Os | 3 | Mn | <2 |

| Ru | 15 | Sn | 3 | As | <2 |

| Sb | 11 | Cu | 3 | Co | <2 |

| Al | 7 | Pb | 3 | Mo | <2 |

| Ca | 6 | Mg | 2 | Te | <2 |

| Se | 5 | Bi | 2 | ||

| Si | 4 | Ag | 2 |

Electrical Properties

Electrical resistivity ( µOhmcm ): 5.1@20°C

Superconductivity critical temperature ( K ): 0.1100

Temperature coefficient ( K⁻¹ ): 0.00450 @0-100°C

Thermal emf against Pt (cold 0C – hot 100C) ( mV ): 0.65

Thermal Properties

Coefficient of thermal expansion ( x10⁻⁶ K⁻¹ ): 6.800 @0-100°C

Latent heat of evaporation ( J g⁻¹ ): 3186

Latent heat of fusion ( J g⁻¹ ): 135.00

Specific heat ( J K⁻¹ kg⁻¹ ): 133.0 @25°C

Thermal conductivity ( W m⁻¹ K⁻¹ ): 147.00 @0-100°C

Mechanical Properties

Bulk modulus ( GPa ) ( Hard / Soft ): 371.0

Hardness – Vickers ( KGF mm⁻² ) ( Hard ): 650

Hardness – Vickers ( KGF mm⁻² ) ( Soft ): 200 – 300

Material condition: Hard / Soft

Poisson’s ratio ( Hard / Soft ): 0.260

Tensile modulus ( GPa ) ( Hard / Soft ): 528.00

Tensile strength ( MPa ) ( Hard ): 1200.00

Tensile strength ( MPa ) ( Soft ): 550.00 – 1100.00

Iridium Crucibles are crucial in various high-temperature processes, particularly in semiconductor manufacturing, materials science, and research. Some critical applications of Iridium Crucibles include:

Our Iridium Crucibles are clearly labeled externally to ensure efficient identification and quality control. To prevent any damage during storage or transportation, we take great care.

Iridium is a rare and precious metal that possesses several unique properties. It is the second densest naturally occurring element, with a density of 22.56 g/cm³. Iridium is known for its exceptional hardness, brittleness, and resistance to corrosion. It also exhibits remarkable thermal stability, even at extremely high temperatures of up to 2,000°C. Iridium is primarily used in the form of alloys, particularly with platinum, to take advantage of its hardness and corrosion resistance, making it ideal for various high-temperature applications. This article will explore the important role that iridium crucibles play in processes such as single crystal growth and other demanding applications.

Iridium crucibles are indispensable tools for a wide range of high-temperature industrial and research applications, particularly those involving the growth of high-purity crystals and advanced materials processing.

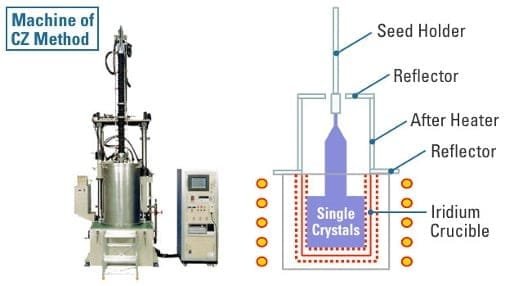

Single Crystal Growth:

We can only use pure materials like platinum, iridium, gold, and rhenium to grow single crystals from oxide melts. The crucible shape is usually cylindrical. The choice of material depends on the melting temperature, atmosphere, and melt constituents. Iridium crucibles are used for growing crystals of high melting oxides (e.g., sapphire, spinel) for laser technology and the optical industry at temperatures up to about 2300°C. Precious metals are only used in the Czochralski and Bridgman-Stockbarger processes and the crystallization from hydrothermal solutions. Gold and platinum are suitable for oxidizing atmospheres, while iridium should only be used under inert conditions because iridium oxides evaporate and can cause significant weight loss. Under reducing conditions, harmful melt constituents can damage the iridium crucible.

Iridium crucibles are used to grow a variety of high-purity single crystals, including:

High-Purity Metal Melting: Iridium crucibles are perfect for melting precious metals like platinum, ensuring purity and minimal contamination.

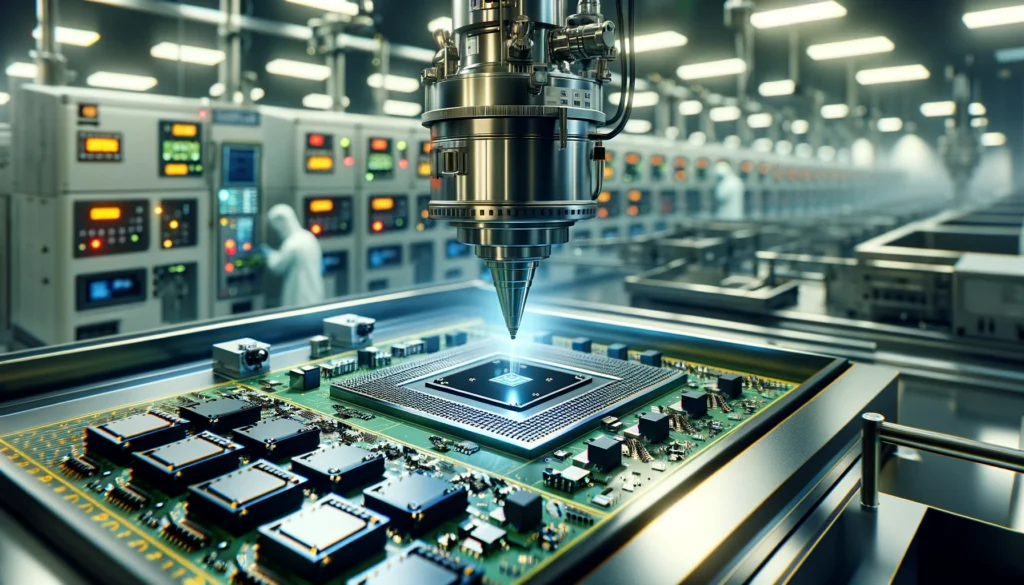

Semiconductor Manufacturing:

Iridium crucibles are used to contain and control the high-temperature environments required for growing semiconductor crystals and thin films.

Specialty Glass Production: Their resistance to corrosion and high temperatures makes them suitable for producing various types of specialty glass.

Scientific Research: These crucibles are used in material science and chemistry for high-temperature experiments.

LED Materials Manufacturing: Iridium crucibles help synthesize LED materials, maintaining purity and thermal stability.

Iridium crucibles play an indispensable role in the crystal growth process. These specialized containers are essential for managing the critical thermal environment required to form high-quality crystals.

Thermal Environment Control

The iridium crucible contains the molten material from which the crystal is grown. It maintains precise control over the temperature and temperature gradients within the melt. This carefully regulated thermal environment is crucial for preserving the purity and structural integrity of the developing crystal.

Melt Containment

The iridium crucible physically holds and confines the molten material. This allows the seed crystal, positioned either at the bottom or suspended within the melt, to grow into a larger, high-quality crystal. The crucible’s corrosion-resistant properties ensure the melt remains free of contamination during the lengthy growth process.

Crystal Purity and Integrity

Iridium’s exceptional heat tolerance and chemical inertness make it an ideal material for crystal growth crucibles. It can withstand the extremely high temperatures necessary without reacting with or contaminating the molten source material. This preserves the purity and structural perfection of the resulting crystal.

Czochralski Process: This technique involves dipping a seed crystal into molten material within the crucible and slowly lifting it out, allowing a single crystal to form upon the seed.

Bridgman-Stockbarger Technique: Here, the crucible passes through a temperature gradient to allow controlled crystal growth from the melt.

Other Techniques: The floating zone technique and others also benefit from iridium’s high-temperature capabilities.

When choosing an iridium crucible for crystal growth applications, there are several important factors to consider.

First, the size and shape of the crucible should be chosen based on the specific crystal growth technique and the amount of material being processed. The crucible should be large enough to hold the melt, but not so large that it affects temperature control and uniformity. Common shapes for crucibles include flat-bottomed and arc-bottomed designs, each with their own advantages for different growth methods.

Another factor to consider is customization options. Iridium crucibles can be custom-made to fit the exact requirements of a particular crystal growth system. This allows for optimization of factors such as crucible dimensions, wall thickness, and other design elements to improve the efficiency and performance of the growth process.

Cost is also an important consideration. Iridium is a rare and valuable metal with pretty high price, so iridium crucibles have a high initial cost. However, their exceptional durability and ability to maintain precise temperature control can lead to significant long-term savings by improving crystal quality and growth yields. The market price of iridium itself is also a key factor in determining the cost of crucibles.

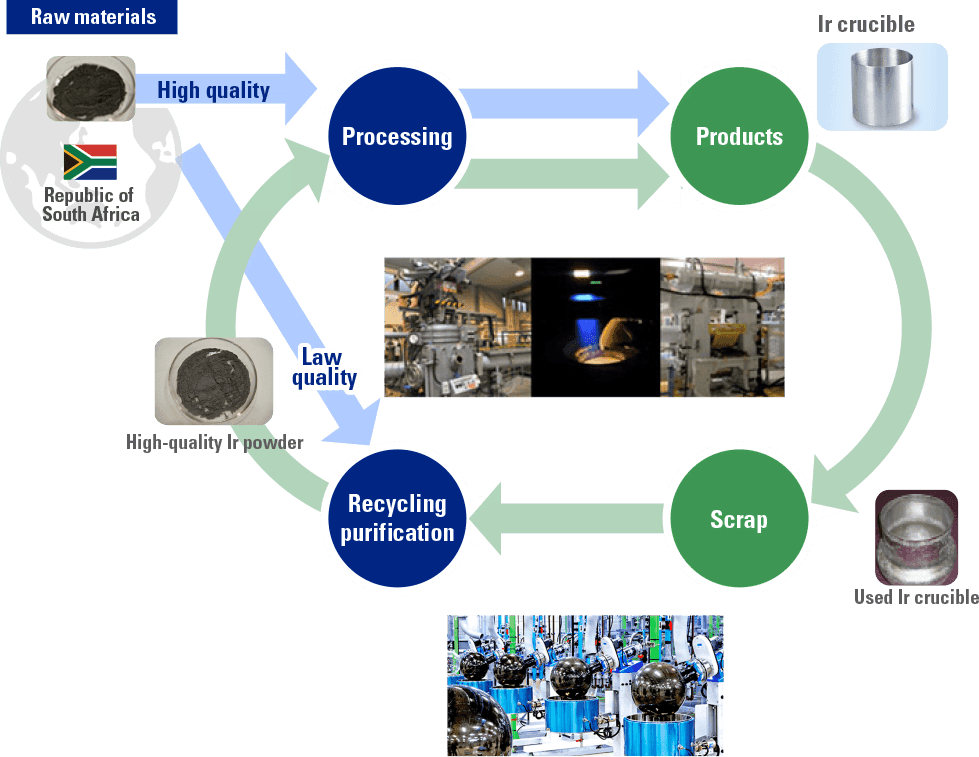

The production of high-quality iridium crucibles involves sourcing pure raw materials, advanced melting and purification techniques, precision fabrication, and rigorous quality control – all of which are critical to enabling the crucibles’ use in demanding crystal growth applications.

Raw Material Sourcing and Purification

Melting and Ingot Formation

Crucible Fabrication

Quality Control

Iridium Crucible Maintenance

Cleaning and Storage

At MetalsTek, we take great pride in providing top-notch iridium crucibles that meet the demanding requirements of today’s industries. Our dedication to quality, coupled with our capability to tailor targets to precise sizes and compositions, positions us as the go-to choice for businesses looking to push boundaries and achieve greatness.