Menu

Chromium is a critical alloying element in steels. Adding chromium to steel results in the formation of stainless steel, which is known for its exceptional corrosion resistance, strength, and durability.

Material: Cobalt-Chromium

Compositions: Co-58%~69%, Cr 26%~30%, Customized

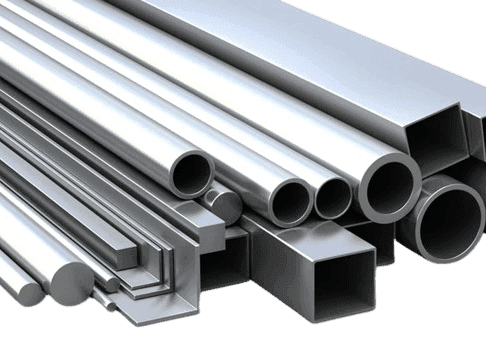

Product Form: Wire, Rod, Tube, Plate/Sheet, Machined Parts

Sizes: Tailored Size, or According to Drawing

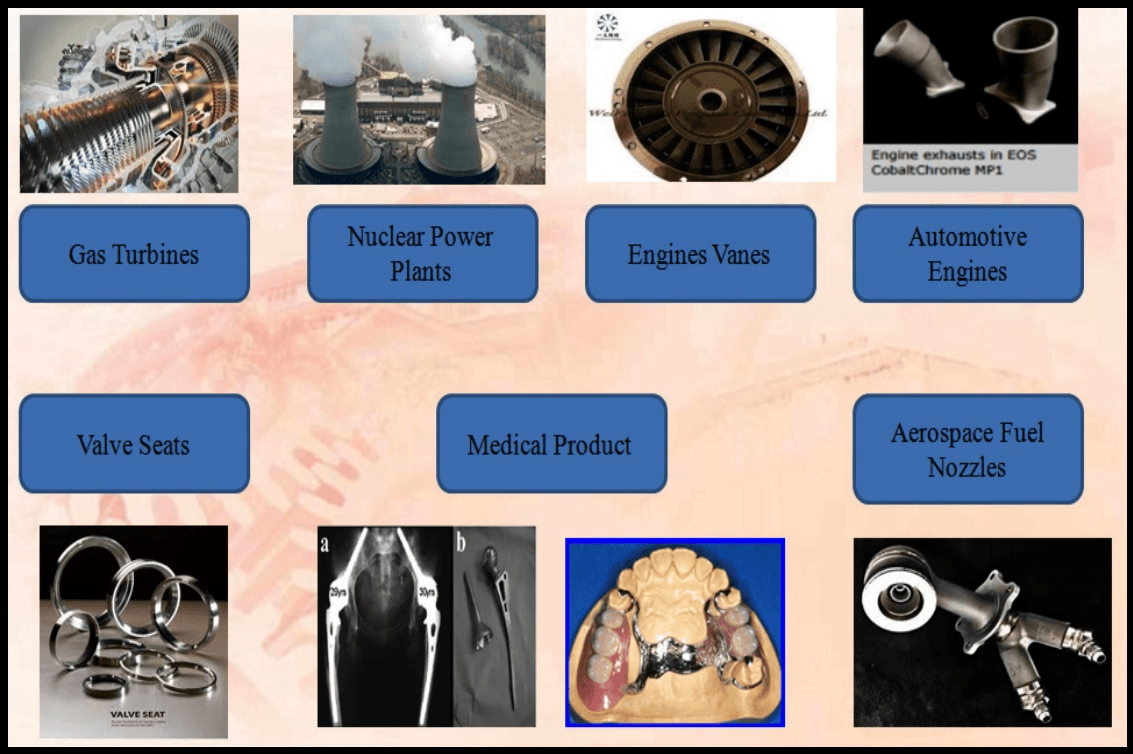

Applications: Gas Turbines, Medical Implants, Orthopedic Implants

Material: Aluminum Chromium, Al-Cr

Compositions (wt%): 50/50, 70/30, 80/20, 90/10, 96/4, Customized

Product Form: Ingot, Granules, Machined Parts

Sizes: Tailored Size, or According to Drawing

Material: Nickel, Chromium

Composition: Ni-Cr 80/20, Can be Customized

Product Form: Wire, Rod, Tube, Plate/Sheet, Machined Parts

Sizes: Tailored Size, or According to Drawing

Applications: Heating Elements, Electrical Ignitions, Hard-wearing Coatings, Aircraft Engine Turbines

Material: 316 Stainless Steel

Compositions: Fe-Cr-Ni-Mo-Mn, Can be Customized

Product Form: Powder, Wire/Rope, Rod/Bar, Ring/Tube/Capillary, Plate/Sheet/Strip, Mesh/Foam/Filter, Machined Parts

Sizes: Tailored Size or According to Drawing

316 stainless steel, known as marine grade steel, famous for its exceptional corrosion resistance, finds applications across diverse industries:

1.Marine Equipment: Boat fittings, propeller shafts, marine fasteners.

2.Food and Beverage SanitaryProcessing: Tanks, pipes, valves in food processing, brewing, pharmaceuticals. (Sanitary Valves, Pipes, and Fittings are Available)

3.Chemical Processing: Reactors, heat exchangers, storage tanks in corrosive environments.

4.Medical Devices: Surgical instruments, implants, medical equipment.

5.Architecture and Construction: Handrails, facades, structural components.

6.Aerospace and Automotive: Aircraft fittings, exhaust systems, components in harsh environments.

7.Oil and Gas Industry: Offshore platforms, pipelines, petrochemical plants.

Its corrosion resistance, durability, and mechanical properties make it indispensable in these applications.

Material: Monel Steel

Grades: N04400 /401/404/R405/05502, N05500,

Product Form: Ring/Tube/Capillary, Fittings, Rod/Bar, Plate/Sheet/Strip, Wire/Rope, Mesh/Foam/Filter, Machined Parts

Sizes: Tailored Size or According to Drawing

Tube

Seamless pipe&tube; welded pipe&tube; capillary tube; coil tube; thick-walled pipe

Fittings

Elbow; flange; reducer; tee; pipe cap

Bars

Round bar&rod; flat bar; square bar; hexagon bar

Sheets

Sheet; plate; coil; strip

Wires

Wire; wire rod; filler metal; welding electrode

Material: Inconel Steel

Grades: N06600 /601/601GC/602CA/603XL/617/625/625LCF/686/690/693/706/718/718SPF/725/740H/X-750/751/MA754/758/783

Product Form: Ring/Tube/Capillary, Fittings, Rod/Bar, Plate/Sheet/Strip, Wire/Rope, Mesh/Foam/Filter, Machined Parts

Sizes: Tailored Size or According to Drawing

Tube

Seamless pipe&tube; welded pipe&tube; capillary tube; coil tube; thick-walled pipe

Fittings

Elbow; flange; reducer; tee; pipe cap

Bars

Round bar&rod; flat bar; square bar; hexagon bar

Sheets

Sheet; plate; coil; strip

Wires

Wire; wire rod; filler metal; welding electrode

Material: Incoloy Steel

Grades: N08800/800H/800HT/803/825/832/864/890/903/907/908/909/925/926/945/945X/MA956/A-286/8020/8028/DS/8330/8367(25-6HN)/S31277(27-7MO)

Product Form: Ring/Tube/Capillary, Fittings, Rod/Bar, Plate/Sheet/Strip, Wire/Rope, Mesh/Foam/Filter, Machined Parts

Sizes: Tailored Size or According to Drawing

Tube

Seamless pipe&tube; welded pipe&tube; capillary tube; coil tube; thick-walled pipe

Fittings

Elbow; flange; reducer; tee; pipe cap

Bars

Round bar&rod; flat bar; square bar; hexagon bar

Sheets

Sheet; plate; coil; strip

Wires

Wire; wire rod; filler metal; welding electrode

Material: Hastelloy Steel

Grades: B(10001)/B-2(N10665)/B-3(N10675)/C/C-2000(N06200)/C-22(N06022)/C-22HS(N07022)/C-276(N10276)/C-4(N06455)/G-3(N06985)/G-30(N06030)/G-35(N06035)/N(N10003)/S(N06635)/W(N10004)/X(N06002)

Product Form: Ring/Tube/Capillary, Fittings, Rod/Bar, Plate/Sheet/Strip, Wire/Rope, Mesh/Foam/Filter, Machined Parts

Sizes: Tailored Size or According to Drawing

Tube

Seamless pipe&tube; welded pipe&tube; capillary tube; coil tube; thick-walled pipe

Fittings

Elbow; flange; reducer; tee; pipe cap

Bars

Round bar&rod; flat bar; square bar; hexagon bar

Sheets

Sheet; plate; coil; strip

Wires

Wire; wire rod; filler metal; welding electrode

Material: HY-180 High Strength Alloy Steel

Composition: Fe78.72%, Ni10%, Co8%, Cr2%, Mo1%, C0.13%, Mn0.1%, Si0.05%

Density: 7.75g/cc

Form: Rod, Bar, Sheet, Plate, Machined Parts

Applications: Aerospace, Automotive, Defence, Vehicle Components, Structural Engineering, Industrial Machinery

Typical Industry Specification: vehicle components, structural engineering, industrial machinery, and aerospace structures

HY-180 is a premium-grade alloy steel, recognized for its outstanding strength, toughness, and wear resistance. With a carefully balanced composition and a production process optimized for performance, HY-180 offers unparalleled reliability for applications in heavy machinery, automotive, and other high-stress environments.

HY-180 alloy steel features a precise blend of elements, ensuring superior mechanical properties:

Available in a wide range of sizes and forms, including sheets, bars, rods, and custom-machined components.

HY-180 is manufactured using advanced metallurgical techniques to ensure precision and quality:

HY-180 High Strength Alloy Steel is a versatile material used across a range of industries:

By selecting HY-180, you’re investing in:

Alloy Type: Inconel, Duplex, Monel, Incoloy, Hastelloy, AUS Stainless Steel

Product Form: Powder, Wire/Rope, Rod/Bar, Ring/Tube/Capillary, Plate/Sheet/Strip, Mesh/Foam/Filter, Machined Parts

Sizes: Tailored Size, or According to Drawing

Chromium Alloys, known for their exceptional properties, find widespread use across multiple sectors due to their unique combination of attributes such as corrosion resistance, hardness, strength, and heat resistance. Chromium Alloys are primarily composed of chromium as the predominant element, often supplemented with other alloying elements to tailor their properties to specific applications. Adding these elements can enhance mechanical strength, machinability, and resistance to environmental factors.

Chromium Alloys, notably stainless steels such as 304, 316, and 316L, offer exceptional corrosion resistance due to chromium’s presence. High-carbon chromium steels provide outstanding hardness and wear resistance, which makes them ideal for bearings and cutting tools. Additionally, chromium-based alloys, often combined with cobalt or nickel, excel in heat-resistant applications like gas turbines and industrial furnaces.

Beyond stainless steel, chromium alloys like Hastelloy and Inconel offer remarkable corrosion resistance in harsh environments. Chromium-Molybdenum alloys balance strength, toughness, and weldability, making them suitable for pressure vessels and automotive components.

Typical Chromium Alloys include Stainless Steel, Cobalt Chromium Alloy, Nickel Chromium Alloy, Chromium Molybdenum Alloy, and more.

Chromium alloys have a wide range of applications across various industries. Some of the critical applications include:

1. Steel Production: Chromium is extensively used in steel production. It is added to steel as high-carbon and other grades of ferrochromium alloys to improve mechanical properties, increase hardening, and enhance corrosion resistance.

2. Metallurgy: Chromium, in the form of ferrochromium, is used as an alloying element in metallurgy to impart corrosion resistance to various materials such as tool steels, stainless steels, nickel-based alloys, and superalloys.

3. Refractories and Foundries: Refractory-grade chromite is used to manufacture magnesia-chrome bricks used in the extractive metallurgy of platinum group metals. Additionally, foundry sands made of chromite fines are utilized to make molds for casting nonferrous metals.

4. Dyes and Pigments: Chromium compounds are valued as pigments for their vivid colors. They are used to color ceramics and in various industrial applications.

5. Decorative Applications: Hard chromium plating extensively protects steel parts and provides a silvery bright finish.

6. Aerospace and Non-Aerospace Industries: Chromium alloys such as 30Al/70Cr and 44Al/56Cr are available for critical coating applications in these industries, providing corrosion resistance, strength, and hardness to the coated materials.

7. Electrical Heating and Heat-Resistant Parts: Nickel-chromium alloys are mainly used as wires for electrical heating and heat-resistant parts in various applications.

Chromium Alloys are highly valued for their corrosion resistance, strength, and heat-resistant properties, making them essential in diverse industrial sectors such as metallurgy, manufacturing, and aerospace.

Our Chromium Alloys are externally labeled for efficient identification and quality control. We take great care to prevent damage during storage and transportation.