Menu

MetalsTek Engineering supplies a variety of quality Tungsten Electrodes for all welding needs.

Material: Pure Tungsten or Doped Tungsten

Density: 18.2~19.0 g/cc

Standard Sizes: Diameter 1mm, 1.6mm, 2mm, 2.4mm, 3.2mm, 4mm, 4.8mm, 6.4mm, 8mm, and 10mm; Length 50mm, 75mm, 150mm, 175mm, 178mm

Tolerance: +/-0.05mm * +/-0.1mm

Other: Size Can be Customized

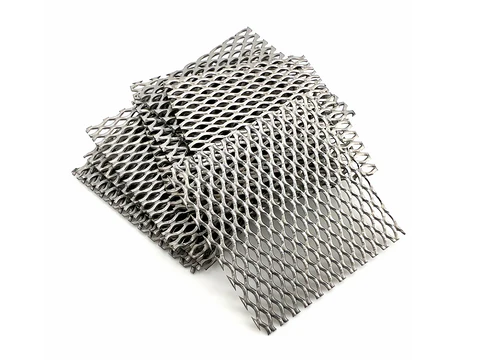

Material: Tungsten

Purity: W 99.95% Min

Size & Mesh Size: Can be Customized

Other Materials: Molybdenum, Titanium, Nickel, Copper, Aluminum, Silver, Stainless Steel

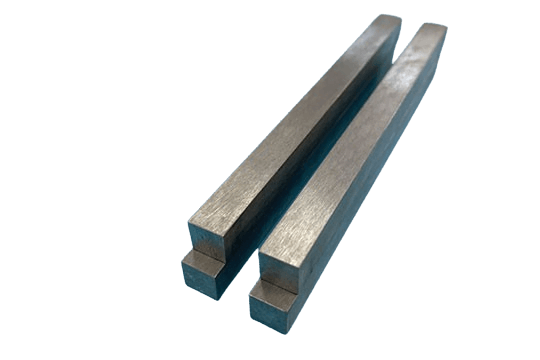

Material: Silver, WC

Composition: Ag 50%, 60%, 70%

Density: 11.2~12.2 g/cc

HRB Hardness: 57~85

Size: Can be Customized

Tungsten electrodes and tungsten alloy electrodes are crucial components in welding applications, known for their high melting points, excellent conductivity, and durability. In its pure form or as part of tungsten alloys, they are widely used in various welding processes, particularly in tungsten inert gas (TIG) or gas tungsten arc welding (GTAW).

Tungsten alloy electrodes are composed of tungsten combined with other elements, such as thorium, cerium, lanthanum, or zirconium, forming tungsten alloys. Alloyed tungsten electrodes offer advantages like improved electron emission, better arc stability, and increased current-carrying capacity. For example, thoriated tungsten electrodes (with thorium) are known for their longevity and excellent high-current performance.

| Item Name | Oxide Additives (%) | Impurities (%) | Electric Discharged Power (eV) | Color |

|---|---|---|---|---|

| Pure Tungsten Electrode | N/A | < 0.2% | 4.5eV | Green |

| Thoriated Tungsten Electrode | ThO2 (0.90% ~ 1.20%) | < 0.2% | 2.0eV ~ 3.0eV | Yellow |

| ThO2 (1.80% ~ 2.20%) | < 0.2% | 2.0eV ~ 3.0eV | Red | |

| ThO2 (2.80% ~ 3.20%) | < 0.2% | 2.0eV ~ 3.0eV | Violet | |

| ThO2 (3.80% ~ 4.20%) | < 0.2% | 2.0eV ~ 3.0eV | Orange | |

| Ceriated Tungsten Electrode | CeO2 (1.80% ~ 2.20%) | < 0.2% | 2.7eV ~ 2.8eV | Grey |

| Lanthanated Tungsten Electrode | La2O3 (0.80% ~ 1.20%) | < 0.2% | 2.8eV ~ 3.2eV | Black |

| La2O3 (1.30% ~ 1.70%) | < 0.2% | 2.8eV ~ 3.0eV | Golden | |

| La2O3 (1.80% ~ 2.20%) | < 0.2% | 2.6eV ~ 2.7eV | Azure | |

| Yttriated Tungsten Electrode | Y2O3 (1.80% ~ 2.20%) | < 0.2% | 2.0eV ~ 3.9eV | Blue |

| Zirconiated Tungsten Electrode | ZrO2 (0.20 ~ 0.40%) | < 0.2% | 2.6eV ~ 2.7eV | Brown |

| ZrO2 (0.70% ~ 0.90%) | < 0.2% | 2.6eV ~ 2.7eV | White | |

| Composite Electrode | CeO2, ThO2, La2O3, ZrO2, Y2O3 (1.50% ~ 3.00%) | < 0.2% | N/A | Light Green |

Tungsten electrodes find versatile applications in welding processes, particularly in Tungsten Inert Gas (TIG) or Gas Tungsten Arc Welding (GTAW). Here are some key applications:

Tungsten electrodes are a crucial component in TIG welding, providing stability, precision, and versatility in various welding applications across different industries. The choice of tungsten electrode type depends on factors such as the material being welded, the welding process, and the desired weld characteristics.

Our Tungsten Electrodes are meticulously tagged and externally labeled, ensuring both efficient identification and rigorous quality control. We prioritize utmost care to prevent any potential damage that may occur during storage or transportation.