Menu

As a trusted supplier with extensive experience, MetalsTek Engineering provides high-quality tantalum carbide, contributing to advancing industries that rely on cutting-edge materials.w

Purity: 99%, 99.5%, 99.9%, 99.99%

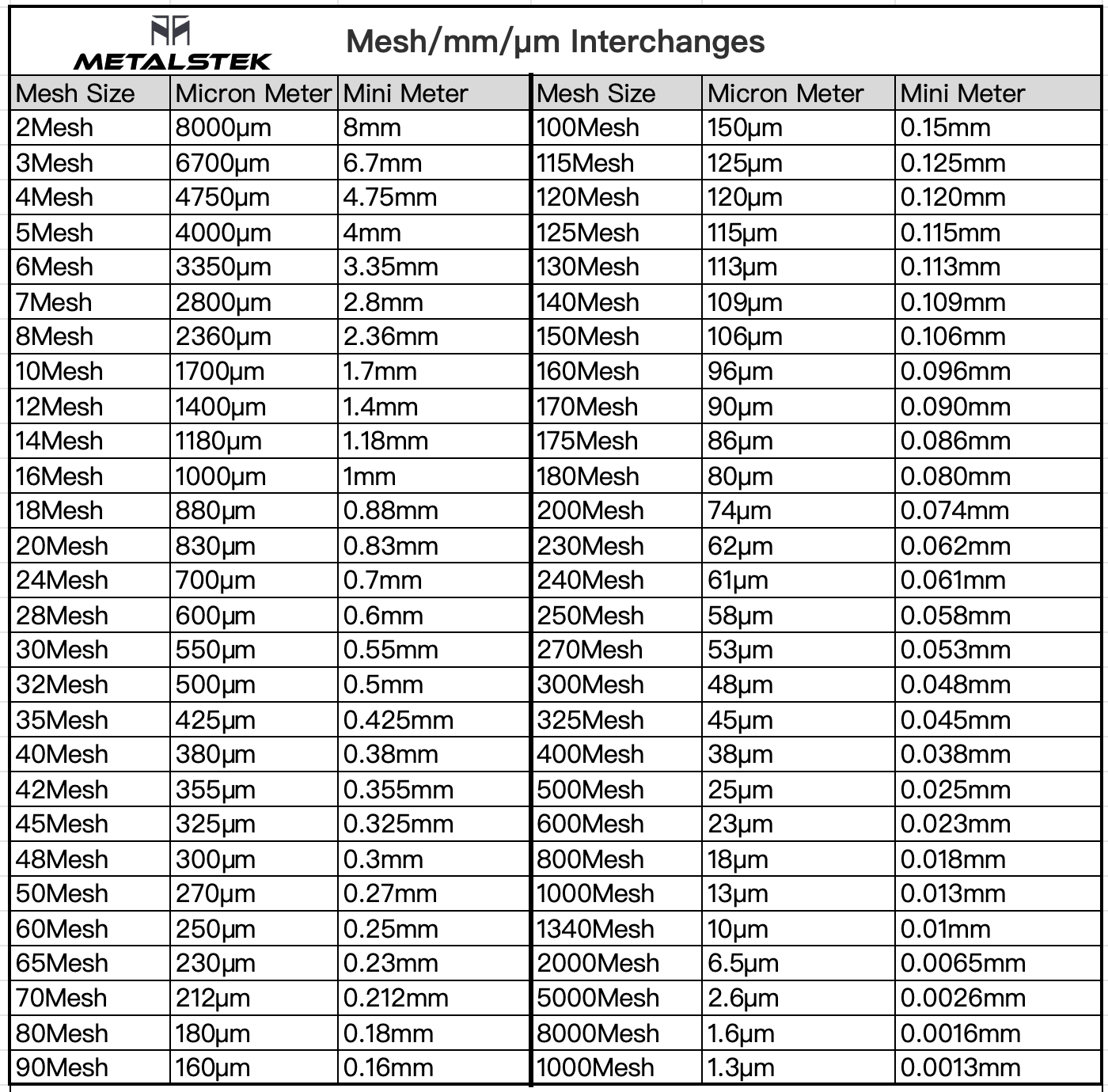

Particle Size: 0.5um to 2um

Other: Size and Composition Can be Customized

CAS #: 12070-06-3

Tantalum Carbide, a robust and brown refractory ceramic material, exhibits hardness and high thermal and electrical conductivity in its powder form (TaC). Employing sintering processes, it enhances oxidation resistance, hot-hardness, and temperature strength in steel processing. Our tantalum carbide powder is available in minimal grain sizes and finds frequent use in deposition, evaporation processes, and applications requiring high surface areas.

In vital sectors like the automobile and aerospace industries, Tantalum Carbides (TaC) play a crucial role in enhancing the performance of hard metal cutting tools. Tantalum niobium carbides contribute significantly to improvements in oxidation resistance, hot-hardness, high-temperature strength, and resistance to crater wear during steel processing. Their thermal conductivity also aids in resisting thermal cracking caused by effects like thermal shock during milling processes.

Purity: 99.9%, 99.99%, 99.999%, 99.9999%

Particle Size: 600μm, 1,000μm

Specific Surface Area: 600μm 25 m2/g, 1,000μm 15 m2/g

Tap Density: 600μm 3.29 g/cc, 1,000μm 3.3 g/cc

Morphology: Cubic

Melting Point: 3,880°C

Purity: 99% Min

Particle Size: 1,000nm

Specific Surface Area: 15 m2/g

Density: 14.5 g/cc

Morphology: Cubic

Melting Point: 3,880°C

Purity: 99.5% Min

Average Particle Size: 10~60um

Carbon (%): 6.12~6.22

Oxygen (%): 0.40% Max

Fluidity: 16 s/50g

Applications: Powder Metallurgy, Cutting Tools, Fine Ceramics, CVD, etc

Material: Ta2C (A kind of MXene)

Purity: 99% Min

Particle Size: 14.3 g/cm3

Density: 14.3 g/cc

Other: Etched by Hydrofluoric Acid

Application: Energy Storage Devices

Material: TaC, NbC

Composition(TaC:NbC): 90:10, 80:20, 70:30, 60:40, 50:50

Color: Dark Grey

Other: Composition and Particle Size Can be Customized

Tantalum Carbide is a versatile material with various applications, such as electronic components, ultrahigh-temperature applications, aerospace, and military equipment. Its unique properties, such as high hardness, melting point, and ability to form a dielectric oxide layer, make it an ideal material for these applications

Hardness and Melting Point: Tantalum carbide is one of the hardest known materials, ranking close to diamond on the Mohs scale. It has an exceptionally high melting point, exceeding 3,800 degrees Celsius (6,872 degrees Fahrenheit).

Refractory Properties: Tantalum carbide is classified as a refractory ceramic, meaning it can withstand high temperatures without melting or deforming. This property makes it valuable in applications involving extreme heat.

| Grade | TaC-1 | TaC-2 | TaC-3 |

|---|---|---|---|

| TaC(%) | ≥99.5 | >99.0 | >99.0 |

| Carbon(%) | ≥6.20 | ≥6.20 | ≥6.20 |

| Free Carbon(%) | ≤0.10 | ≤0.15 | ≤0.15 |

| Fe(%) | ≤0.05 | ≤0.1 | ≤0.20 |

| Si(%) | ≤0.008 | ≤0.01 | ≤0.020 |

| Al(%) | ≤0.005 | ≤0.005 | ≤0.01 |

| Ti(%) | ≤0.008 | ≤0.015 | ≤0.02 |

| N(%) | ≤0.025 | ≤0.05 | ≤0.05 |

| Na(%) | ≤0.003 | ≤0.005 | ≤0.02 |

| Ca(%) | ≤0.005 | ≤0.005 | ≤0.01 |

| K(%) | ≤0.003 | ≤0.005 | ≤0.01 |

| Nb(%) | ≤0.3 | ≤1.0 | ≤1.0 |

Tantalum Carbide (TaC) finds a range of applications due to its unique properties. Some of the notable applications include:

These applications showcase the versatility of tantalum carbide across various industries, ranging from manufacturing and steel processing to electronics and aerospace.

Our Tantalum Carbide are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.