Menu

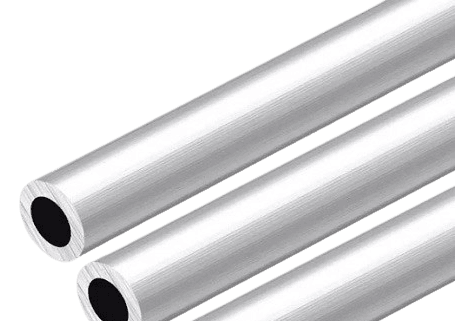

MetalsTek Engineering offers a wide range of titanium tubing products, including seamless tubing, welded tubing, spiral tubing, titanium capillary tubing, U-bent tubing, titanium tubing stub ends, and titanium screwed fittings. Our high-quality titanium tubing is competitively available to meet your specific requirements. Explore the versatility and reliability of MetalsTek Engineering’s Titanium Tubes, ensuring precision and excellence in every application.

Material: Commercially Pure Titanium, C.P Titanium, Titanium Alloy

Grade: Gr.1~Gr.9, Gr.23 / C.P. Ti, Ti-6Al-4V, Ti-6Al-4V ELI, Ti-5Al-2.5Sn, Ti-3Al-2.5V, Ti-15333, Ti-38644, Ti-6Al-7Nb, Ti-662, Ti-6242, Ti-1023, Ti-4322 and Ti-0.2Pd etc.

Standard: ASTM B338, B337, B861, ASME SB338, VdTÜV 230/2

Size: OD2~800mm * Wall Thick0.1~20mm * Length

Surface: Pickled, Polished, or Customized

Material: Titanium, Ti

Purity: 99.9% Min

Size: OD4~100mm * Length 10~1,000mm, or Customized

| Physical Prop. | Tensile Strength | Yield Strength | Elongation | Section Shrinkage |

|---|---|---|---|---|

| Unit | Mpa | Mpa | % | % |

| Ti-G1 | 240 | 170 | 25 | 30 |

| Ti-G2 | 345 | 275 | 20 | 30 |

| Type | N≤ | C≤ | H≤ | Fe≤ | O≤ | Others≤ |

|---|---|---|---|---|---|---|

| Ti-G1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | 0.4 |

| Ti-G2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 0.4 |

Material: Titanium and Ti Alloys

Standard: ASTM B337/ASME SB337, ASTM B338/ASME SB338, ASTM B861/ASME SB861

Grade: Gr.1, Gr.2, Gr.9

Outside Diameter: 0.2 – 8 mm (0.00787 – 0.315 in.)

Wall Thickness: 0.05 -2 mm (0.00197 -0.0787 in.)

More About Titanium Capillary

Material: Titanium and Ti Alloys

Standard: ASTM B337/ASME SB337, ASTM B338/ASME SB338, ASTM B861/ASME SB861

Grade: Gr.1 ~ Gr.23

Size: Tailored Sizes

Typical Application: Marine, Aircraft Hydraulic Systems, Oil and gas Extraction

Material: Titanium and Ti Alloys

Standard: ASTM B337/ASME SB337, ASTM B338/ASME SB338, ASTM B861/ASME SB861

Grade: Gr.1 ~ Gr.23

Size: Tailored Sizes

Typical Application: Chemical and Petrochemical Uses

Material: Titanium and Ti Alloys

Standard: ASTM B337/ASME SB337, ASTM B338/ASME SB338, ASTM B861/ASME SB861

Grade: Gr.1 ~ Gr.23

Size: Tailored Sizes

Typical Application: Structural Uses in Construction

Material: Titanium and Ti Alloys

Standard: ASTM B337/ASME SB337, ASTM B338/ASME SB338, ASTM B861/ASME SB861

Grade: Gr.1 ~ Gr.23

Size: Tailored Sizes

Type: Inner Thread, Outer Thread

Material: Titanium and Ti Alloys

Standard: ASTM B337/ASME SB337, ASTM B338/ASME SB338, ASTM B861/ASME SB861

Grade: Gr.1 ~ Gr.23

Size: Tailored Sizes

Use: Safeguard Against External Materials

Titanium Tubes and Pipes, crafted from the resilient metal titanium, are pivotal components across a spectrum of industries. Renowned for their exceptional strength-to-weight ratio and corrosion resistance, Titanium Tubes find applications in aerospace, chemical processing, medical devices, and more. These tubes serve as conduits for fluids, gases, and electrical wires, offering reliability and durability even in demanding environments.

Capillary tubes are utilized in various industries due to their ability to transport fluids based on the viscosity of the material. Titanium is commonly chosen for capillary tube applications due to its strength, resistance to corrosion, and compatibility with biological systems.

Titanium comes in various grades, each with unique properties and applications. Here is a guide to some common titanium tubing grades:

Titanium Tubing is a versatile material with various applications across various industries due to its unique properties, such as high strength, lightweight characteristics, and excellent corrosion resistance. Some typical Titanium Tubing applications include:

Our Titanium Tubes and Pipes are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

In a world where materials serve their purpose and enhance your project’s quality and effectiveness, titanium tubing stands out. Known for its strength, lightweight nature, and resistance to corrosion, titanium tubing has become a vital component in various industries. From aerospace to medical technology and chemical processing, the right tubing can significantly impact. This comprehensive guide provides all the necessary information to make well-informed decisions about titanium pipes and tubing.

Titanium tubing is a type of tubing made from titanium and its alloys. It is designed to be strong and durable, even in tough conditions. These tubes come in different sizes and grades to fit different needs. They can be used for many things, from small tubes for medical devices to big pipes for airplanes. Titanium tubing is known for being very good and reliable.

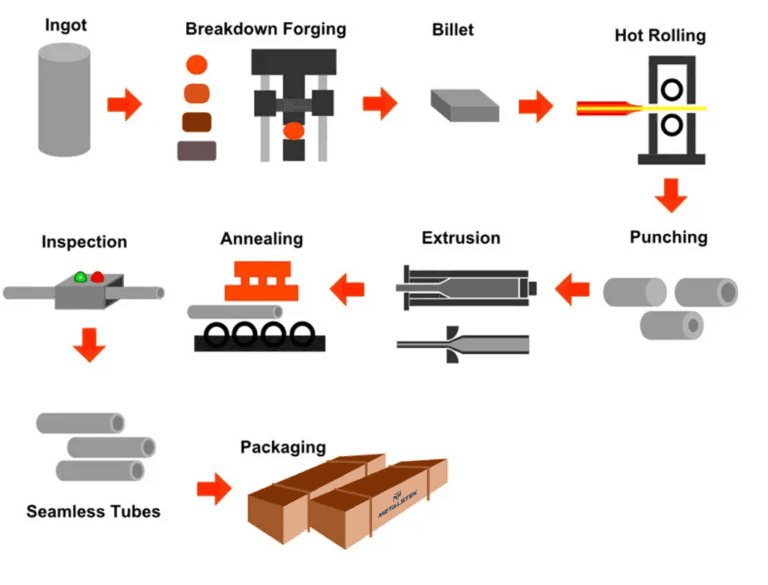

Titanium tubing production involves several key steps to ensure the highest quality and performance.

Seamless and Welded Tubes

Seamless tubes are made by extracting titanium into a tube shape directly from molten titanium; this method is preferred for its ability to maintain uniformity across the tube’s body.

Welded tubes, on the other hand, are made by forming a flat sheet of titanium into a tube and welding the edge. Each method has its specific advantages in terms of cost, strength, and application suitability.

Titanium tubes offer a plethora of features that make them a prime choice for critical and high-performance applications. These include:

Overview of Our Titanium Tubing & Pipe Specifications

Manufacturing Standard | ASTM B 337 ASME SB 337 / ASTM B 338 ASME SB 338, ASTM B337 B861 B862, DIN, JIS. | |

Grade | Gr1, Gr2, Gr3, Gr4, Gr5 (Ti-6Al-4V), Gr7 (Ti-0.2Pd), Gr9 (Ti-3Al-2.5V), Gr12 (Ti-0.3Mo-0.8Ni), Gr23 (Ti-6Al-4V ELI), etc. | |

Type | Seamless, Welded, Fabricated, ERW, EFW | |

Size | Seamless Titanium Tube | OD: 0.5~330mm ; WT:4~219mm ; Length: less than 14 meters |

Titanium Welded Tube | OD: 1~1200mm ; WT: 0.1~500mm ; Length: less than 14 meters | |

Tube End | Plain End, Beveled End, Treaded | |

Surface | Acid surface, Polishing, Sand Blasting Finished, Bright, Polished | |

Test Certificate | EN10204 3.1 UT other Destructive & No Destructive Tests | |

Application |

| |

Titanium Grades Features and Applications

The properties of titanium tubing and pipe vary depending on the grade, making each grade suitable for specific applications. The table below presents a clear overview of the main uses for each grade, enabling users to make well-informed choices based on their individual requirements.

Grade | Feature | Typical Applications |

Gr1 | Pure Titanium, low strength, and high ductility. | Chemical processing, marine applications |

Gr2 | Pure Titanium, most used with moderate strength. | Power generation, desalination, aerospace |

Gr3 | Pure Titanium, stronger than Gr1 and Gr2. | Airframes, aircraft engines |

Gr4 | Pure Titanium, strongest among the pure grades. | Medical implants, industrial applications |

Gr5 (Ti-6Al-4V) | High strength alloy, most widely used titanium alloy. | Aerospace structures, surgical implants |

Gr7 (Ti-0.2Pd) | Superior corrosion resistance in reducing & oxidizing environments. | Chemical processes, power generation |

Gr9 (Ti-3Al-2.5V) | Low weight, high strength. | Bicycle frames, golf clubs, aerospace |

Gr12 (Ti-0.3Mo-0.8Ni) | Enhanced corrosion resistance. | Chemical processes, marine applications |

Gr23 (Ti-6Al-4V ELI) | A more refined version of Gr5. | Medical implants, dental implants |

At MetalsTek, we pride ourselves on our robust supply chain and production capabilities. We can produce various titanium tubing sizes and forms, meeting stringent international standards. Our annual output is scalable according to market demands, ensuring reliable delivery schedules and flexible order volumes.

Seamless and welded tubeses are the two primary modelt we are good at.

Type | Outer Diameter | Thickness | Length |

Titanium Seamless Tube | 0.5-330mm | 0.4-20mm | Max 150,00mm |

Titanium Welded Tube | 114-20000mm | 0.5-50mm | Max 150,00mm |

Our titanium tubing is available in various forms to suit diverse applications, from round and square tubes for structural applications to capillary tubes used in medical instruments.

MetalsTek is a reputable manufacturer that specializes in producing a wide range of titanium tubing and pipes. They offer various forms such as seamless, welded, round, rectangular, and square tubes/pipes. Additionally, they also provide coiled, finned, corrugated, and capillary tubes.

With our extensive knowledge and experience, MetalsTek can provide customized solutions to fulfill all your pipe and tube needs, making it a convenient one-stop shop for all your requirements.

Choosing the right titanium tubing involves considering factors such as mechanical stress, environmental conditions, and budget. Below are the basic aspects you should consider to ensure a wise investing:

At MetalsTek, our team of experts is always ready to assist you in choosing the right product that perfectly matches your requirements.

Titanium tubing finds its application in several critical sectors:

We provide a range of surface finishing options to enhance the appearance and performance of our titanium tubing. These options include polishing for a reflective finish, anodizing for color and improved resistance to corrosion, and coating for added durability.

In addition to supplying titanium tubes, MetalsTek offers additional services such as custom cutting, bending, and end-forming, designed to meet the unique needs of your project.

Choosing MetalsTek as your titanium tubing supplier means opting for quality, reliability, and excellent customer service. Our commitment to providing high-quality, competitively priced tubing solutions is unmatched, making us the preferred partner for industries worldwide.

Decades of Industry Leadership: MetalsTek has developed substantial expertise in the titanium sector over the years. This depth of experience ensures the delivery of precision-engineered products with every order.

Uncompromising Quality Assurance: MetalsTek is steadfast in its commitment to quality. Each product is subject to thorough inspections to meet international standards including ASTM, ASME, and DIN, guaranteeing high-quality outcomes.

Wide Range of Titanium Products: From Grade 1 (Gr1) to Grade 23 (Gr23), and from seamless to welded configurations in tubing and pipes, MetalsTek offers a diverse inventory to meet various industry requirements.

Affordable Excellence: At MetalsTek, we balance high quality with competitive pricing. Our aim is to provide exceptional value, ensuring our clients receive premium titanium products at reasonable costs.

Prompt Delivery Services: With an efficient production system and a strong logistics network, MetalsTek ensures fast and reliable delivery, helping keep your projects on track and on time.

Expert Technical Support: Our team of expert engineers is available to provide insights and support, helping clients choose the perfect products for their specific needs, thus optimizing project outcomes.

Dedicated to Customer Satisfaction: The client is central to our operations at MetalsTek. Our customer service team is committed to clear communication and complete satisfaction, always prioritizing your needs.

By partnering with MetalsTek, you are doing more than just choosing a supplier; you are engaging with a reliable partner dedicated to advancing your business success.

Choosing the right supplier for titanium pipe and tubing is easy when you understand titanium’s properties and applications.

MetalsTek is a top supplier with over a decade of experience in the titanium industry. We handle projects of any size and provide materials that meet the highest standards of finish and specification. Our team is always available to offer expert advice and support. Whether you need a standard or custom product, choosing MetalsTek means every detail and requirement is addressed with precision and dedication.