Menu

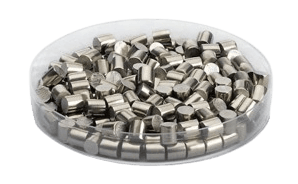

MetalsTek Engineering specializes in producing and supplying high-purity Zirconium Evaporation Materials and an extensive range of evaporation materials. Our offerings include pellet, powder, and granule forms, up to 99.999% pure, with the flexibility for customized solutions to meet specific requirements. At MetalsTek Engineering, we are proud to deliver top-quality materials tailored to the unique needs of our clients.

Purity: 99%~99.5%

Form: Pellet, Granule, Powder, or Customized

Size: 3*3mm, 2*2mm, or Customized

Application: Deposition Process of CVD, PVD, Semiconductors

| Molecular Weight | 91.22 |

|---|---|

| Melting Point | 1,852 °C |

| Boiling Point | 3,580 °C |

| Density | 6,506 kg/m3 |

| Electrical Resistivity | 40.0 microhm-cm at 20°C |

| Electronegativity | 1.4 Paulings |

| Heat of Fusion | 5.50 Cal/gm mole |

| Heat of Vaporization | 120 K-Cal/gm atom at 4,377 °C |

| Poisson’s Ratio | 0.34 |

| Specific Heat | 0.0671 Cal/g/K at 25 °C |

| Tensile Strength | 230 MPa |

| Thermal Conductivity | 0.227 W/cm/K at 298.2 K |

| Thermal Expansion | 5.7 µm·m-1·K-1 at 25°C |

| Vickers Hardness | 903 MPa |

| Young’s Modulus | 88 GPa |

Purity: 99.9%, 99.99%, 99.999%, 99.9999%

Particle Size: 600μm, 1,000μm

Specific Surface Area: 600μm 25 m2/g, 1,000μm 15 m2/g

Tap Density: 600μm 3.29 g/cc, 1,000μm 3.3 g/cc

Morphology: Cubic

Melting Point: 3,880°C

Purity: 99.9%

Feature: Yttria Fully Stabilized

Form: Pellet, Granule, Powder, or Customized

Size: Customized

Application: Solid Oxide Fuel Cells, CVD, PVD, Semiconductors, Optics, Coatings

Purity: Zr/Ni-99.5%, Ni/Zr-99.9%

Properties: 1,845°C M.P, 6.49g/cc Density, 10.8 W/m·K Thermal Conductivity

Form: Pellet, Granule, Powder, or Customized

Size: Customized

Application: Deposition Process of CVD, PVD, Semiconductors, Optics

Purity: 99.5%, 99.9%

Properties: 3,428°C M.P, 6.08g/cc Density, 20.7 W/m·K Thermal Conductivity

Form: Pellet, Granule, Powder, or Customized

Size: Customized

Application: Deposition Process of CVD, PVD, Semiconductors

Purity: 99.5%, 99.9%

Properties: 3,422°C M.P, 13.5g/cc Density, 22 W/m·K Thermal Conductivity

Form: Pellet, Granule, Powder, or Customized

Size: Customized

Application: Deposition Process of CVD, PVD, Semiconductors

Purity: 99.5%

Properties: 2,980°C M.P, 7.09g/cc Density, 105.23 M.W, Yellow Brown Color

Form: Pellet, Granule, Powder, or Customized

Size: Customized

Application: Deposition Process of CVD, PVD, Semiconductors

Purity: 99.5%

Properties: 3,532°C M.P, 6.73g/cc Density, 103.23 M.W

Form: Pellet, Granule, Powder, or Customized

Size: Customized

Application: Thin-Film Coatings, Optical Coatings, Microelectronics, Aerospace Components

Model: Zr/Cu, BaZrO3, PbZrO3, PLZT, PbZrTiO3, SrZrO3, ZrF4, ZrSi2, ZrB2

Purity: 99.5%, 99.9%, 99.95%

Form: Pellet, Granule, Powder, or Customized

Size: Customized

Application: Deposition Process of CVD, PVD, Semiconductors

Zirconium and Zirconium-Related Evaporation Materials are crucial components in physical vapor deposition (PVD), chemical vapor deposition (CVD), or thermal evaporation. These materials are designed for applications where a thin zirconium film must be deposited onto a substrate.

Material Type | Zirconium | Z Ratio | 0.6 |

Symbol | Zr | E-Beam | Excellent |

Atomic Weight | 40 | Thermal Evaporation Techniques | Boat: W |

Atomic Number | 13 | ||

Color/Appearance | Silvery White, Metallic | Temp. (°C) for Given Vap. Press. (Torr) | 10-8: 1,477 |

10-6: 1,702 | |||

10-4: 1,987 | |||

Thermal Conductivity | 22.7 W/m.K | Export Control (ECCN) | 1C234 |

Melting Point | 1,852 °C | Comments | Alloys with W. Films oxidize readily. |

Coefficient of Thermal Expansion | 5.7 x 10-6/K | Suggested QCM Crystal | Alloy Crystal: 750-1002-G10**** |

Theoretical Density | 6.49 g/cc |

Based on the form of zirconium evaporation materials used and the deposition techniques employed in different industries, Zirconium Evaporation Materials find applications in various industries and processes. Some typical applications include:

Our Zirconium Evaporation Materials are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.