Menu

MetalsTek Engineering is synonymous with reliability and excellence in the realm of high-purity Iron Evaporation Materials.

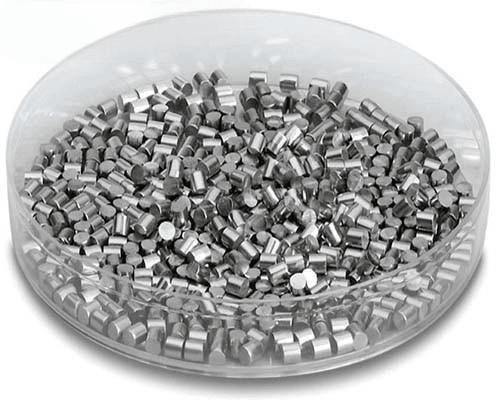

Material: Iron, 99.9%~99.99%

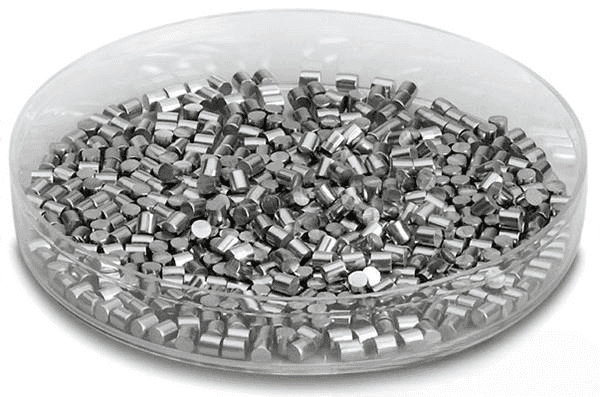

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Applications: Deposition Process, CVD, PVD, Optics Coatings, Displays

Material: Iron Oxide, 99.9%

Properties: ≈1,538°C M.P., 5.18g/cc Density

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Iron Oxide, 99.9%

Properties: ≈1,565°C M.P., 5.24g/cc Density

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Cobalt Iron, 99.9%~99.95%

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Iron Aluminum, 99.9%~99.99%

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Applications: Solar Cells, Magnetic Storage Media, Coatings, etc.

Material: Iron Chromium, 99.9%~99.95%

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Iron Manganese, 99.9%

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Iron Nickel, 99.9%~99.99%

Composition: Can be Customized

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Iron Carbide, 99.5%

Properties: ≈1,505°C M.P., 7.7g/cc Density

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Iron Nitride, 99.5%

Properties: ≈1,473°C M.P., 6.77g/cc Density

Form: Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Iron Sulfide, 99.9%

Properties: ≈1,194°C M.P., 4.84g/cc Density

Form: Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Iron Sulfide, 99.5%

Properties: 1,389°C M.P., 7.3g/cc Density

Form: Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Iron Silicon, 99.9%~99.99%

Properties: 1,220°C M.P., 4.74g/cc Density

Form: Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Iron is a widely used metal with a metallic-gray color. It is ductile, ferromagnetic, and oxidizes easily when exposed to oxygen. It has a melting point of 1,535°C, a density of 7.86 g/cc, and a vapor pressure of 10-4 Torr at 1,180°C. Iron is used in various applications, such as tools, automobiles, and machinery. By combining it with carbon, we can create steel, which is a crucial material in the construction and automotive industries. Iron also plays a vital biological role in facilitating oxygen transport in blood. In manufacturing processes, it is evaporated under vacuum conditions to create layers for semiconductor production, magnetic storage media, fuel cells, and other applications.

Material Type | Iron | Coefficient of Thermal Expansion | 11.8 x 10-6/K |

Symbol | Fe | Theoretical Density | 7.86g/cc |

Atomic Weight | 55.845 | Ferromagnetic | Magnetic Material |

Atomic Number | 26 | Z Ratio | 0.349 |

Appearance | Lustrous, Metallic, Grayish Tinge | Sputter | DC |

Thermal Conductivity | 80 W/m.K | Max Power Density | 50 Watts/Square Inch |

Melting Point | 1,535°C | Comments | Attacks W. Films hard, smooth. Preheat gently to outgas. |

Iron and iron-related evaporation materials find diverse applications across various industries due to their unique properties. Some key applications include:

These diverse applications highlight the importance of iron and iron-related evaporation materials in modern technology, manufacturing, and scientific research, contributing to innovation and progress across various industries.

Our Iron Evaporation Materials are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.