Menu

MetalsTek Engineering is a leading manufacturer and supplier of Aluminum and Aluminum related Evaporation Materials. We can provide up to 99.9999% high purity Aluminum Evaporation Materials with short lead times and competitive prices.

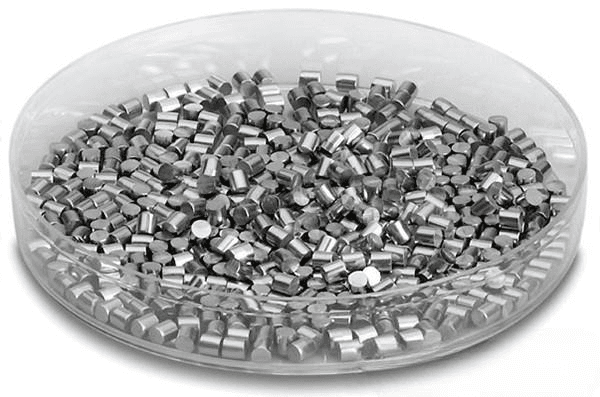

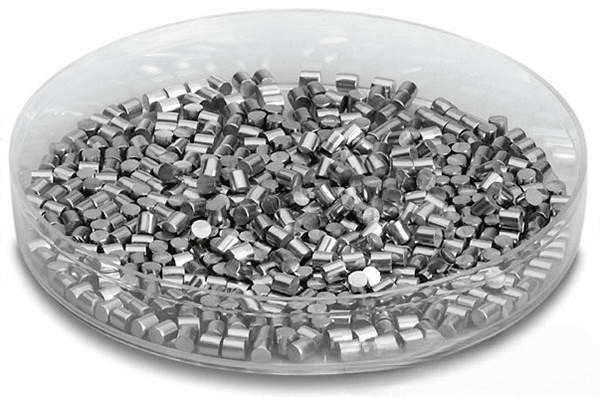

Material: Aluminum

Purity: 99.9%~99.9995%

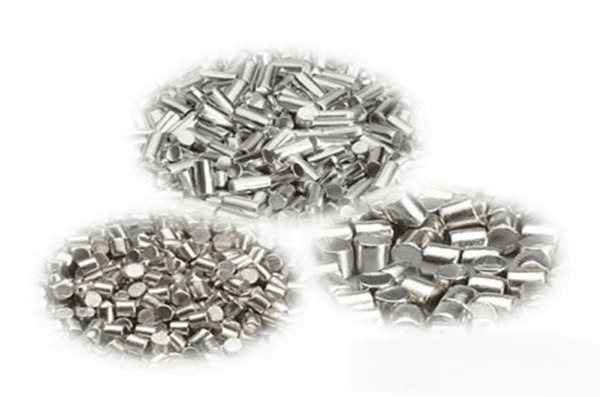

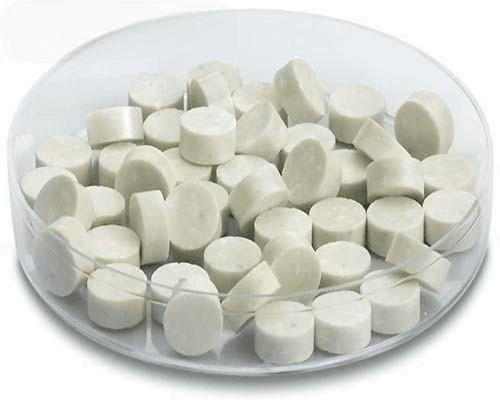

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

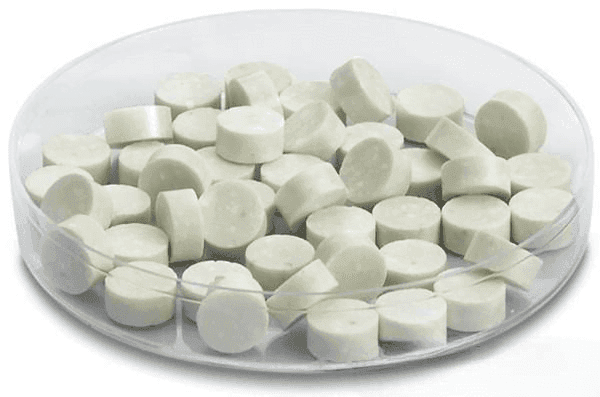

Material: Aluminum Oxide, 99.5%

Compositions: Can be Customized

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Aluminum Chromium, 99.9%~99.9995%

Compositions: Can be Customized

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Aluminum Cobalt, 99.9%~99.95%

Compositions: Can be Customized

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Aluminum Copper, 99.9%~99.999%

Compositions: Can be Customized

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Aluminum Magnesium, 99.9%~99.99%

Compositions: Can be Customized

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Aluminum Nickel, 99.9%~99.99%

Compositions: Can be Customized

Properties: 7.5g/cc Density, 1,385°C M.P.

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Aluminum Scandium, 99.9%~99.95%

Compositions: Can be Customized

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Aluminum Titanium, 99.9%~99.99%

Compositions: Can be Customized

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Aluminum Titanium, 99.9%~99.99%

Compositions: Can be Customized

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Molybdenum Aluminum, 99.9%~99.99%

Form: Pellets, Pieces, Powder, Customized Shapes

Other: Customized Shape, Size, and Purity

Application: Electronics, Optics, Coatings

Material: Molybdenum Aluminum, 99.9%~99.95%

Form: Pellets, Pieces, Powder, Customized Shapes

Other: Customized Shape, Size, and Purity

Application: Electronics, Optics, Coatings

Material: Vanadium Aluminum, 99.9%

Form: Pellets, Pieces, Powder, Customized Shapes

Other: Customized Shape, Size, and Purity

Application: Electronics, Optics, Coatings

Material: Zinc Aluminum, 99.9%~99.99%

Form: Pellets, Pieces, Powder, Customized Shapes

Other: Customized Shape, Size, and Purity

Application: Electronics, Optics, Coatings

Material: Zirconium Aluminum, 99.5%

Form: Pellets, Pieces, Powder, Customized Shapes

Other: Customized Shape, Size, and Purity

Application: Electronics, Optics, Coatings

Material: Zirconium Aluminum, 99.5%~99.9%

Properties: ~3g/cc Density, 2,200 °C M.P.

Form: Pellets, Pieces, Powder, Customized Shapes

Other: Customized Shape, Size, and Purity

Application: Electronics, Optics, Coatings

Aluminum Evaporation Materials are crucial substances used in thin film deposition processes to ensure high-quality deposited films. These materials play a vital role in semiconductor deposition, chemical vapor deposition (CVD), and physical vapor deposition (PVD) processes. Aluminum evaporation materials are widely employed in the optics field for wear protection, decorative coatings, and display devices. These evaporation granules are carefully handled during storage and transportation to prevent damage and maintain the integrity of the product.

Aluminum is a metal that is widely available and commonly found in everyday items such as kitchen utensils, streetlights, cars, and food packaging. It has a silvery-white appearance, is lightweight, and can be easily molded or bent without breaking. It is not magnetic, and has a density of 2.7 g/cc, a melting point of 660°C, and a vapor pressure of 10-4 Torr at 1,010°C. Aluminum has excellent thermal and electrical conductivity and forms a protective oxide layer that resists corrosion. Although it is moderately strong, its reactivity limits its presence as a free element in nature. Aluminum can be evaporated in a vacuum to create reflective coatings, which are used in automotive headlamps, telescopes, mirrors, toys, and packaging materials. It has a wide range of applications in industries such as aerospace, automotive lighting, OLED technology, and optics due to its unique properties and capabilities.

Material Type | Aluminum | Z Ratio | 1.08 |

Symbol | Al | E-Beam | Excellent |

Atomic Weight | 26.9815386 | Thermal Evaporation Techniques | Basket: W |

Atomic Number | 13 | Crucible: TiB2-BN, BN | |

Color/Appearance | Silvery, Metallic | E-Beam Crucible Liner Material | FABMATE®, Intermetallic |

Thermal Conductivity | 235 W/m.K | Temp. (°C) for Given Vap. Press. (Torr) | 10-8: 677 |

Melting Point | 660 °C | 10-6: 821 | |

Coefficient of Thermal Expansion | 23.1 x 10-6/K | 10-4: 1,010 | |

Theoretical Density | 2.7 g/cc | Comments | Alloys W/Mo/Ta. Flash evap or use BN crucible. |

Aluminum Evaporation Materials are pivotal in numerous industrial applications due to their unique properties, including excellent conductivity, high reflectivity, and strong corrosion resistance. The process of evaporating aluminum allows for the precise deposition of thin aluminum layers onto various substrates, a technique that finds utility in a broad spectrum of fields. Typical applications include:

These applications underscore the versatility and importance of aluminum and aluminum-related evaporation materials across various industries, leveraging their distinctive properties to meet specific technical requirements and innovate new products.

Our Aluminum Evaporation Materials are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.