Menu

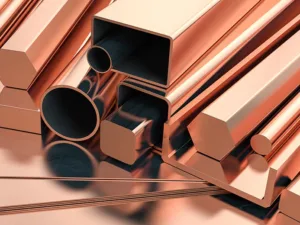

MetalsTek Engineering is a trusted worldwide manufacturer and supplier of Cu-DHP, copper deoxidezed. We have large inventory of Cu-DHP and can produce products according to drawings and designs. Our Cu-DHP material includes C1201, C1220, C12000, C12200, TP1, TP2.

Material: Cu-DHP

Composition: Cu-99.85%, P-0.005% ~ 0.040%

Shape: Ring, Round Tube, Square Tube, or Customized

Size: Tailored Sizes

Surfaces: Polished or Customized

Material: Cu-DHP

Composition: Cu-99.85%, P-0.005% ~ 0.040%

Shape: Rod, Bar, Hollow Bar, Hexagon Bar, or Customized

Size: Tailored Sizes

Surfaces: Polished or Customized

Material: Cu-DHP

Composition: Cu-99.85%, P-0.005% ~ 0.040%

Shape: Sheet, Foil, Strip, Ribbon, or Customized

Size: Tailored Sizes

Surfaces: Polished or Customized

Material: Cu-DHP

Composition: Cu-99.85%, P-0.005% ~ 0.040%

Shape: Sheet, Plate, Square Bar, or Customized

Size: Tailored Sizes

Surfaces: Polished or Customized

Cu-DHP, also known as SF-Cu or Copper-Deoxidized High Phosphorus, is oxygen-free and a type of copper alloy known for its high corrosion resistance and excellent thermal and electrical conductivity.

Phosphorus-deoxidized copper has suitable welding and cold bending performance and generally does not tend to “hydrogen disease.” It can be processed and used in a reducing atmosphere, but it is not suitable for processing and use in an oxidizing atmosphere.

C1201, C1220, C12000, C12200, TP1, TP2

TP1 has less residual phosphorus than TP2, so its electrical and thermal conductivity is higher than that of TP2. TP1 and TP2 are mainly applied in pipes, and can also be supplied in plates, strips, rods, and wires. Used as gasoline or gas delivery pipes, drainage pipes, condenser pipes, mine pipes, condensers, evaporators, heat exchangers, and train box parts.

| Grade | Cu+Ag | Sn | Pb | Ni | Fe | Sb | S | As | Bi | O |

| C1201 | ≥99.9 | |||||||||

| C1220 | ≥99.97 | 0.002 | 0.003 | 0.002 | 0.004 | 0.002 | 0.004 | 0.002 | 0.001 | 0.002 |

| C12000 | ≥99.9 | |||||||||

| C12200 | ≥99.85 | 0.01 | 0.005 | 0.01 | 0.005 | 0.002 | 0.005 | 0.005 | 0.002 | 0.01 |

| TP1 | ≥99.9 | |||||||||

| TP2 | ≥99.85 | 0.01 | 0.005 | 0.01 | 0.005 | 0.002 | 0.005 | 0.005 | 0.002 | 0.01 |

| Grade | Tensile Strength N/mm2 | Elongation % | Hardness HV |

| C1201 | 245~345 | 8 | 75~120 |

| C1220 | |||

| C12000 | 245~345 | 8 | 75~120 |

| C12200 | 215~275 | 25 | 55~100 |

| TP1 | 245~345 | 8 | 75~120 |

| TP2 | 215~275 | 25 | 55~100 |

If you need specific information on sourcing Cu-DHP or have particular requirements for its use in your products, please feel free to Talk To Us!

Our Cu-DHP products are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.