Menu

MetalsTek Engineering is a leading manufacturer and supplier of Magnesium Metals and Magnesium Aluminum Alloy products. We provide magnesium metals with the highest possible purity and density. We have rich experience in producing custom Magnesium products.

Material: Magnesium, CAS # 7439-95-4

Purity: 99.9%

APS: 60 nm, 14 m2/g Surface Area

Density: 1.24g/cc Bulk Density, 3.39 g/cc Tap Density

Magnesium sputtering targets have a wide range of applications across various industries:

Additive Manufacturing

Nano magnesium powder can be used as a raw material for 3D printing, allowing the production of complex and lightweight structures with high strength and corrosion resistance.

Energy Storage

Due to its high energy density and reactivity, nano magnesium powder is used in rechargeable batteries, such as lithium-ion batteries, to increase capacity and performance.

Aerospace

Magnesium powder is used in aerospace applications due to its high strength-to-weight ratio, such as in the production of lightweight structural components for aircraft and spacecraft.

Pyrotechnics

Nano magnesium powder is used in fireworks and pyrotechnic devices to produce bright, intense white light and sparks.

Catalysis

Magnesium powder can act as a catalyst in various chemical reactions, including hydrogenation, dehydrogenation, and organic synthesis processes.

Water Treatment

Nano magnesium powder can be used to remove pollutants from contaminated water by adsorbing heavy metals and reducing their toxicity.

Biomedical Applications

Due to its biocompatibility, nano magnesium powder is being explored for use in biomedical applications such as bone repair, drug delivery systems, and imaging agents.

Flame Retardants

Magnesium powder can be used as a flame retardant additive to improve the fire resistance of materials like textiles, plastics, and coatings.

Cosmetics

Magnesium powder is used in cosmetic products for its ability to absorb excess sebum, making it an effective ingredient in oil-control and anti-acne skincare products.

Environmental Remediation

Nano magnesium powder can be utilized for the remediation of contaminated soils and water bodies by facilitating the degradation of hazardous pollutants.

Material: Magnesium Or Magnesium Alloy

Purity: 99.9% or Customized Compositions

Size: Tailored Size, Coil Spool

Other: Material, Shape and Size Can be Customized

At MetalsTek Engineering, we understand that every project is unique. That’s why we offer custom solutions tailored to your specific needs. Our team of experts works closely with you to develop the perfect magnesium wire for your application, ensuring optimal performance and cost-effectiveness.

Contact us today to learn more about our magnesium and magnesium alloy wire offerings and how we can help you achieve your goals.

Material: Magnesium Or Magnesium Alloy

Purity: 99.9% or Customized Compositions

Shape: Round or Square Shape

Size: Tailored Sizes

Other: Material, Shape, and Size Can be Customized

At MetalsTek Engineering, we pride ourselves on our commitment to quality and customer satisfaction. Our magnesium rods are manufactured under strict quality control standards, ensuring reliability and performance. Our expert team is available to assist you in selecting the right magnesium rod for your specific application, providing customized solutions that meet your needs.

Contact us today to learn more about our magnesium rod offerings and discover how we can support your projects with our high-quality materials.

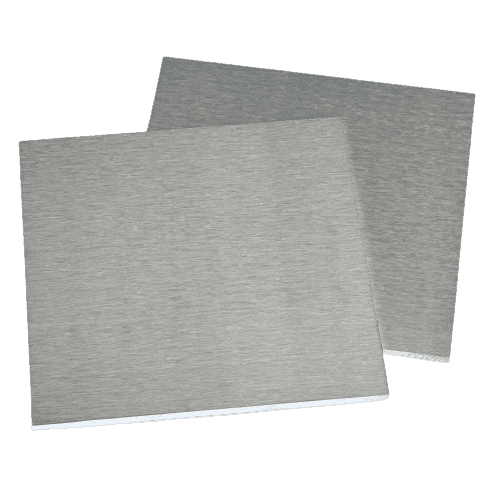

Material: Magnesium Or Magnesium Alloy

Purity: 99.9% or Customized Compositions

Shape: Sheet Plate

Size: Tailored Sizes

Other: Material, Shape, and Size Can be Customized

MetalsTek Engineering offers magnesium sheets and plates in various grades and custom dimensions to meet specific needs. Whether you require standard sizes or tailored solutions, we can provide magnesium sheets and plates to your exact specifications. Our available grades include:

At MetalsTek Engineering, we are dedicated to delivering top-quality magnesium sheets and plates that meet industry standards and exceed customer expectations. Our products undergo strict quality control to ensure they meet the highest standards of durability, performance, and reliability. We pride ourselves on providing flexible order quantities, quick turnaround times, and expert technical support.

For more information about our magnesium sheets and plates or to request a quote, please contact us at [contact details]. Our team of experts is ready to assist you with your specific requirements and help you find the ideal material for your application.

Material: Magnesium, CAS # 7439-95-4

Purity: 99.99%

Form: Chunks, Ingots

Applications: Metal Refining, Metallurgy Alloys, Military, etc.

Elements | Content limit |

Fe | <2 ppm |

Si | <1 ppm |

Ni | <6 ppm |

Cu | <2 ppm |

Al | <1 ppm |

Mn | <3 ppm |

Ti | <1 ppm |

Pb | <39 ppm |

Sn | <1 ppm |

Zn | <45 ppm |

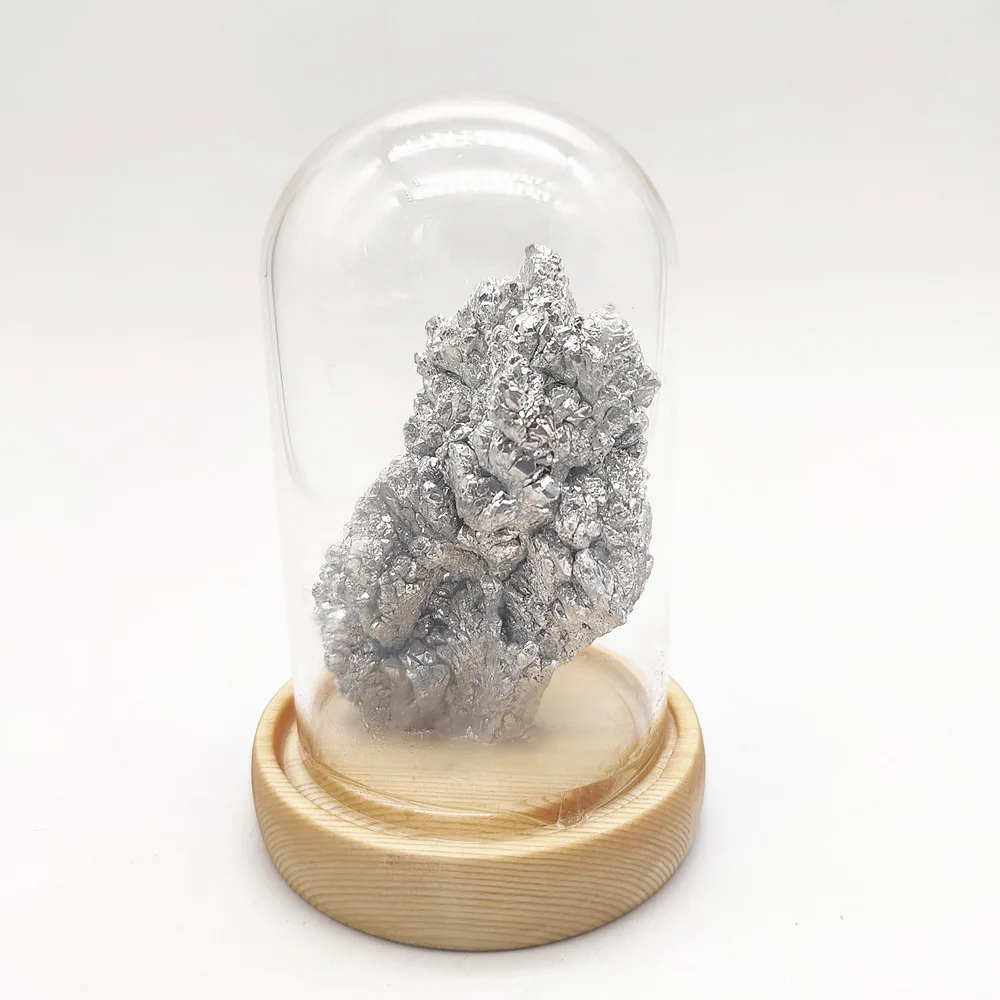

Material: Magnesium, CAS # 7439-95-4

Purity: 99.99%~99.999%

Form: Lumps, Silver Metal, Natural Form

Applications: CVD, PVD, ALD, MOCVD, Low-Temp. Organic Evaporation

Description

MetalsTek supplies Magnesium Lump with the highest achievable density and the smallest average grain size for use in Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) processes such as Thermal and Electron Beam (E-Beam) Evaporation, Low-Temperature Organic Evaporation, Atomic Layer Deposition (ALD), Metallic-Organic and Chemical Vapor Deposition (MOCVD).

Magnesium is commonly used to purify metals like zirconium and hafnium, and a high purity is needed for good quality purification. Magnesium alloys are used in many applications including airplanes and high-performance automobiles.

Specifications

Elements | Al | Si | Ca | Cr | Mn | Fe | Co | Ni |

Content | 0.94 ppm | 0.33 ppm | 1.96 ppm | 0.07 ppm | 1.31 ppm | 2.76 ppm | <0.1 ppm | <0.1 ppm |

Elements | Zn | Cu | Ce | As | Sn | Hg | Pb |

|

Content | 5.37 ppm | 0.38 ppm | <0.1 ppm | <0.1 ppm | <0.1 ppm | <0.1 ppm | 0.57ppm |

Material: Magnesium, CAS # 7439-95-4

Purity: 99.99%~99.999%

Crystal Structure: Hexagonal HCP

Growth Method: Bridgman

Surface: Single or Double/side Polished

Material: Magnesium, CAS # 7439-95-4

Purity: 99.99%~99.999%

Form: Cube

Sizes: 10mm, 25.4mm, Can be Customized

Other: Matching Acrylic Holding Box Available

MOQ: US$50.00

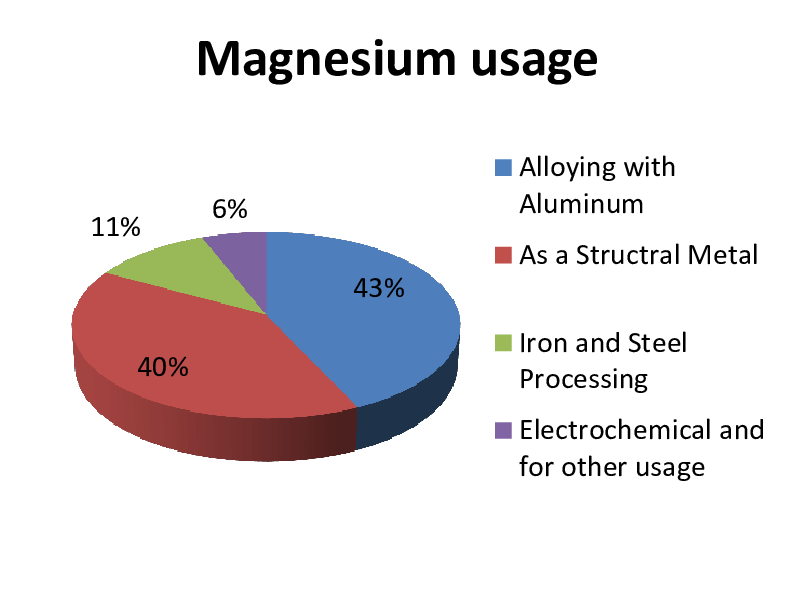

Magnesium is a lightweight, silvery-white metal that is abundant in the Earth’s crust. It has a low density, low melting point, and high reactivity. It is classified as an alkaline earth metal and is found naturally combined with other elements.

Magnesium metal is mainly produced by electrolysis of magnesium salts extracted from brine. It is less dense than aluminum and is used extensively in lightweight alloys for applications in the aerospace, automotive, and electronics industries. Magnesium alloys have excellent strength-to-weight ratios and high damping capacity compared to other structural metals.

Magnesium has a long history, with Joseph Black first identifying it as an element in 1755. Humphry Davy isolated the pure metal in 1808 by electrolysis. Its unique properties and versatility have made it widely used in modern industry and technology.

Material Type | Magnesium | Thermal Evaporation Techniques | Boat: W, Mo, Ta, Cb |

Symbol | Mg | Coil: W | |

Atomic Weight | 24.305 | Basket: W | |

Atomic Number | 12 | Crucible: Al2O3 | |

Appearance | Silvery White, Metallic | E-Beam Crucible Liner Material | FABMATE®, Graphite, Tungsten |

Thermal Conductivity | 160 W/m.K | Temp. (°C) for Given Vap. Press. (Torr) | 10-8: 185 |

Melting Point | 649 °C | 10-6: 247 | |

Coefficient of Thermal Expansion | 8.2 x 10-6/K | 10-4: 327 | |

Theoretical Density | 1.74 g/cc | UN Number | 1869 |

Z Ratio | 1.61 | Comments | Extremely high rates possible. |

E-Beam | Good |

|

MetalsTek Engineering offers magnesium metals in various forms to suit different industrial needs. Whether you require pure magnesium or specific alloys, we provide:

Our Magnesium Metals are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.