Menu

With many experienced experts and engineers, MetalsTek Engineering has rich experience in manufacturing and supplying Mn HEAs.

Material: Fe, Mn, Co, Cr

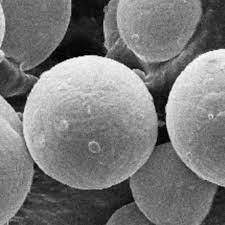

Shape: Spherical Powder

Particle Size: 0-45μm,0-53μm,15-45μm, 15-53μm, 45-105μm

Material: Fe, Cr, Ni, Mn, Al

Shape: Spherical Powder

Particle Size: 0-45μm,0-53μm,15-45μm, 15-53μm, 45-105μm

Material: Fe, Co, Ni, Cr, Mn

Shape: Spherical Powder

Particle Size: 0-45μm,0-53μm,15-45μm, 15-53μm, 45-105μm

Material: Cu, Al, Mn, Ti

Shape: Spherical Powder

Particle Size: 0-45μm,0-53μm,15-45μm, 15-53μm, 45-105μm

Material: CrMnFeCoNi: 1: 1: 1: 1: 1

Impurities: O<500ppm, N<400ppm

Particle Size: 0-45μm,0-53μm,15-45μm, 15-53μm, 45-105μm

Material: Fe, Co, Cr, Mn

Purity: 99%

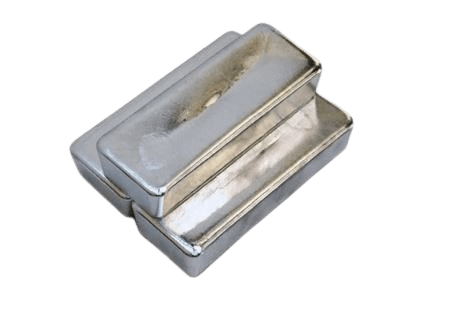

Shape: Ingots, Bars, or Customized Shape

Size: Irregular

Material: Fe, Co, Ni, Cr, Mn

Purity: 99%

Shape: Ingots, Bars, or Customized Shape

Size: Irregular

Material: Fe, Cr, Ni, Mn, Al

Purity: 99%

Shape: Ingots, Bars, or Customized Shape

Size: Irregular

Material: Cu, Al, Mn, Ti

Purity: 99%

Shape: Ingots, Bars, or Customized Shape

Size: Irregular

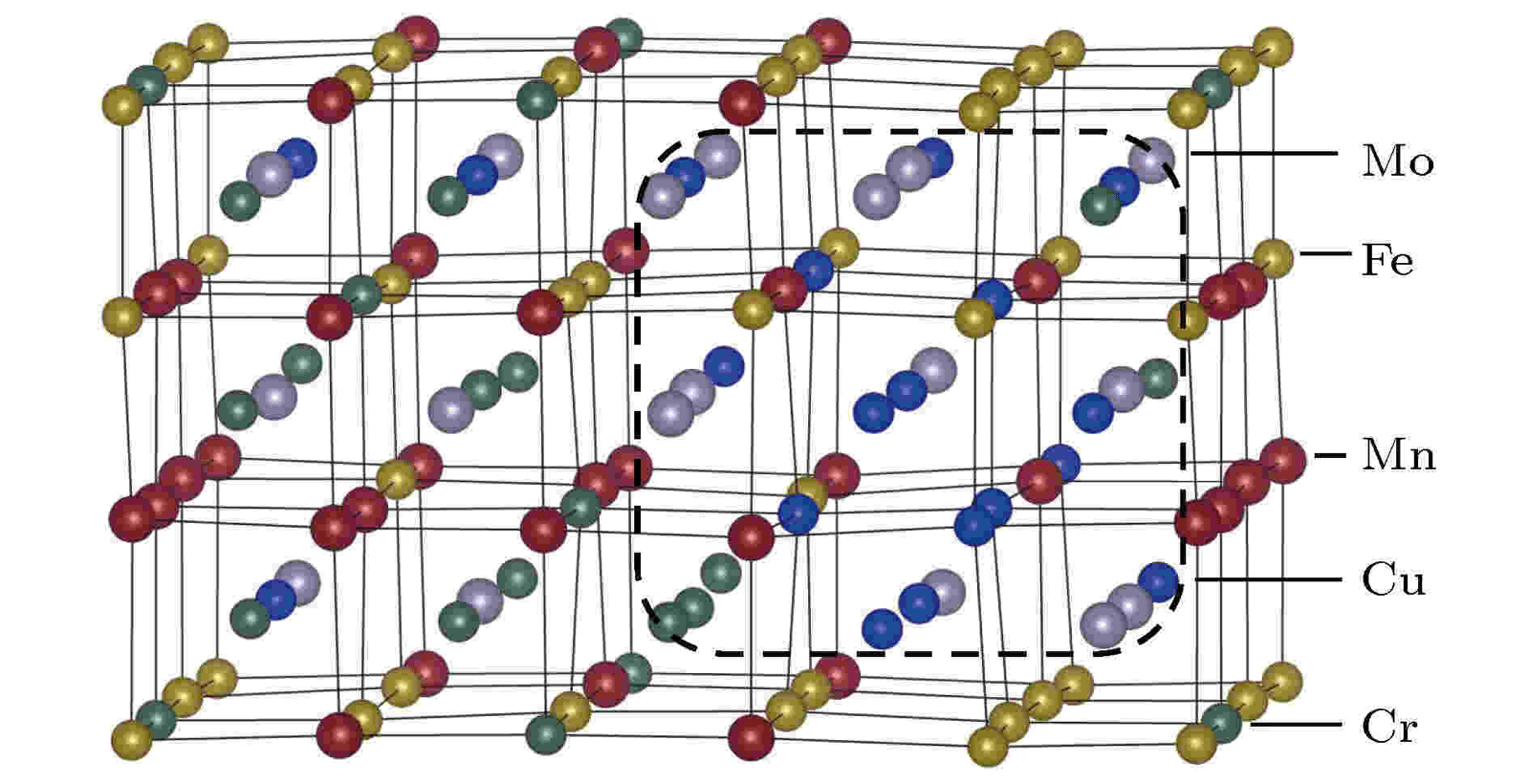

Manganese High Entropy Alloys (Mn-HEAs) represent a cutting-edge class of materials characterized by their complex compositions and exceptional properties. Composed primarily of manganese along with multiple principal elements in roughly equiatomic or near-equiatomic ratios, Mn-HEAs exhibit high strength, good ductility, enhanced corrosion resistance, and thermal stability. These alloys hold tremendous promise across a range of applications, including structural materials for aerospace and automotive industries, wear-resistant coatings, high-temperature components, biomedical implants, and functional devices. While challenges in processing optimization and scalability persist, ongoing research efforts aim to unlock the full potential of manganese high-entropy alloys, paving the way for their integration into diverse industrial sectors and technological innovations.

The applications of Manganese High Entropy Alloys (HEAs) are diverse and significant. Manganese plays a crucial role in enhancing the properties and performance of HEAs, contributing to various applications. Some typical applications of manganese in high entropy alloys include:

These applications highlight the importance of manganese in high entropy alloys and its role in improving the performance and versatility of these advanced materials across different industrial sectors.

We take great care when handling our Manganese High Entropy Alloys to prevent any potential damage during storage or transportation. Through this careful approach, we ensure that our products maintain their original quality and integrity throughout the entire process, which keeps them in their pristine condition for optimal performance upon their arrival.