Menu

MetalsTek Engineering has riche experience in Nickel Metal production. We have large inventory and can supply Nickel Metals and custom Nickel products in various forms, sizes and prices.

Material: Nickel, Ni-99.9%

Form: Nearly Spherical

Particle: 100μm, ≈3m2/g Surface Area

Densities: 1.24g/cc Bulk, 3.39g/cc Tap

Material: Nickel, Ni-99.9%

Form: Nearly Spherical

Particle: 50nm, ≈12m2/g Surface Area

Densities: 1.24g/cc Bulk, 3.39g/cc Tap

Material: Nickel, Ni-99.5%

Form: Spherical Powder

Particle: 50nm, 500nm, 1μm, or Customized

Description

Spherical Nickel Powder is a finely divided form of nickel that has been processed to form spherical-shaped particles. It is commonly produced through various manufacturing processes such as gas atomization, chemical vapor deposition, and electroplating.

About 3D Printing – From Wikipedia

3D printing, also known as additive manufacturing (AM), refers to various processes used to synthesize a three-dimensional object. In 3D printing, successive layers of material are created under computer control. These objects can be of almost any shape or geometry and are produced from a 3D model or another electronic data source. A 3D printer is a type of industrial robot.

Applications of Spherical Ni Powder

Material: Nickel, Ni-99.3%

Particle: +45~150µm, +45~75µm, Precipitated

Densities: 1.24g/cc Bulk, 3.39g/cc Tap

Applications: Salvage Buildup Repairs, Replacement of Monel Steel

Description

Spherical Nickel Powder is a finely divided form of nickel that has been processed to form spherical-shaped particles. It is commonly produced through various manufacturing processes such as gas atomization, chemical vapor deposition, and electroplating.

About 3D Printing – From Wikipedia

3D printing, also known as additive manufacturing (AM), refers to various processes used to synthesize a three-dimensional object. In 3D printing, successive layers of material are created under computer control. These objects can be of almost any shape or geometry and are produced from a 3D model or another electronic data source. A 3D printer is a type of industrial robot.

Applications of Spherical Ni Powder

Material: Nickel, Ni-99.6%

Form: Squares, Pieces

Size: About 30*30*10mm, or Customized

Applications: Anode for Electrolytic Nickel Baths, etc.

Nickel +Cobalt | Cobalt | Copper | Carbon | Iron | Sulfur | Arsenic | Lead | Zinc |

99.6% | 0.0500% | 0.001% | 0.003% | 0.0005% | 0.0002% | 0.0001% | 0.0001% | 0.0003% |

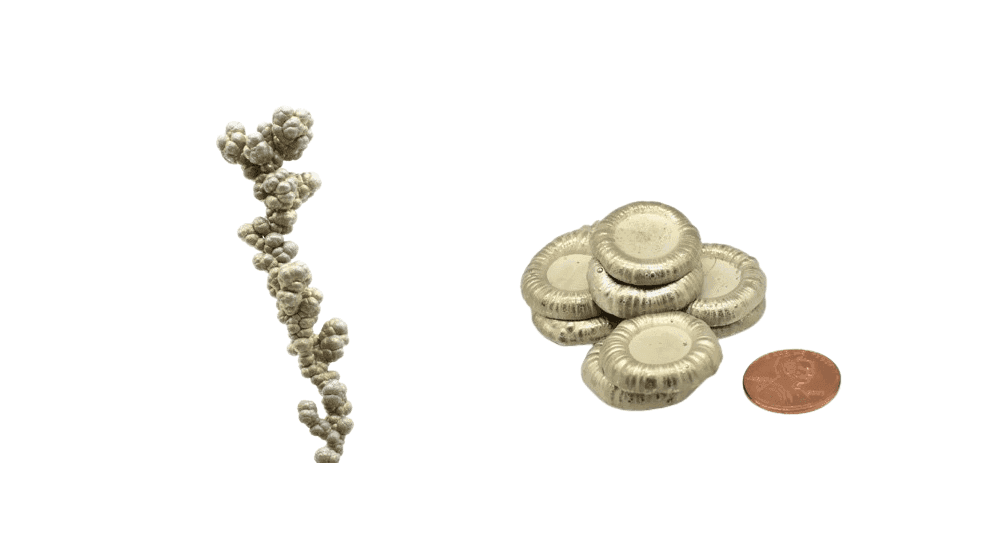

Material: Nickel, Ni-99.95%

Shape: Flower, Disc

Size: Different Weights, or Customized

Other: MOQ 2KG

Nickel +Cobalt | Cobalt | Copper | Carbon | Iron | Sulfur | Arsenic | Lead | Zinc |

99.6% | 0.0500% | 0.001% | 0.003% | 0.0005% | 0.0002% | 0.0001% | 0.0001% | 0.0003% |

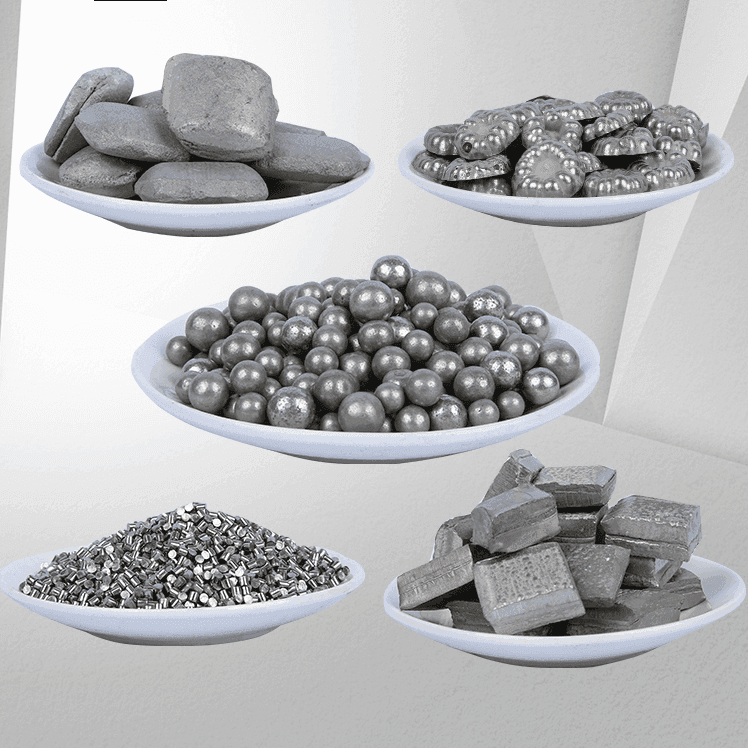

Material: Nickel, Ni

Purity: 99.9%~99.99%

Form: Pellets, Beads, or Customized

Size: 2~6mm Pellets, or Diameter<20mm Beads, Can be Customized

Nickel | Cobalt | Copper | Carbon | Iron | Sulfur | Lead | Zinc |

99.99%% | 0.00002% | 0.00005% | 0.01%% | 0.002% | 0.0002% | 0.00002% | 0.00005% |

Nickel is a versatile and durable metal with an atomic number of 28 and the symbol Ni. It is known for its corrosion resistance, flexibility, and ability to withstand high temperatures. Nickel is extensively used in various industries, including aerospace, automotive, electronics, and manufacturing. It is a crucial component in producing stainless steel, which enhances the material’s strength and resistance to corrosion, making it indispensable in applications requiring durability and longevity. Nickel is also utilized in alloys such as nickel-copper, nickel-chromium, and nickel-titanium, each tailored to specific industrial needs, from electrical wiring to chemical processing equipment. Its versatility and mechanical and chemical properties position Nickel Metal as a cornerstone material in modern manufacturing and engineering applications, illustrating its importance as a foundational element in numerous industrial processes.

Nickel Metal finds a wide range of applications across various industries due to its unique properties and versatility. Some typical applications of nickel metal include:

These applications underscore the significance of Nickel Metal in modern industries and technologies, showcasing its importance as a versatile material with diverse uses.

Our Nickel Metals are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.