Menu

Tin Lead Alloy has been a cornerstone material in the electronics and manufacturing industries for decades. Known for its excellent soldering capabilities, this alloy is widely used in electronic components, coatings, and industrial applications where a reliable metal bond is essential.

MetalsTek Engineering is a trusted manufacturer and supplier of Tin Lead Alloy solder. We can provide high-quality Tin Lead alloy in different compositions, from 50/50 to 95/5, with short lead times and competitive prices.

Material: Tin Lead Alloy

Compositions: Sn:Pb=60:40, 50:50, or Customized

Standard Sizes: 0.3mm~3.0mm, or Customized

Melting Point: 182-215℃

Material: Tin Lead Alloy

Compositions: Sn:Pb=60:40, 50:50, or Customized

Standard Sizes: 0.03~3mm thickness * Width < 100mm * Length, or Customized

Melting Point: 182-215℃

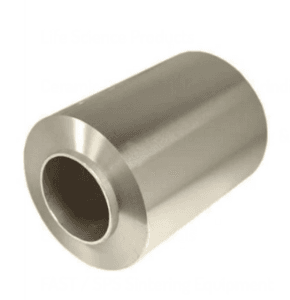

Material: Tin Lead Alloy

Compositions: Sn:Pb=60:40, 50:50, or Customized

Sizes: Customized Sizes

Melting Point: 182-215℃

Tin Lead Alloy is a combination of tin (Sn) and lead (Pb) in varying ratios, commonly found in compositions such as 60/40 (60% tin, 40% lead) and 63/37 (63% tin, 37% lead). We can provide the compositions from 50/50 to 95/5. These ratios affect the alloy’s melting point, mechanical strength, and electrical conductivity. A eutectic composition, like 63/37, is particularly valued because it melts and solidifies at a single temperature, making it ideal for soldering applications.

Good Wetting Ability: It forms strong, reliable bonds with various metals.

Electrical Conductivity: Used extensively in electronics for its stable conductivity.

Ductility & Flexibility: Allows easy application and prevents cracking under stress.

Corrosion Resistance: Provides durability in coated surfaces and soldered joints.

Different Composition Options: Various tin-to-lead ratios offer different mechanical and thermal properties to suit specific needs.

Tin Lead Alloy is most commonly used in soldering for electrical circuits, PCB assembly, and microelectronics. It ensures secure connections and prevents oxidation, thereby enhancing the reliability of electronic devices.

This alloy is widely used in the plating industry to provide a protective, corrosion-resistant layer on metal surfaces. It is also used in the production of bearings due to its lubricating properties.

Tin Lead Alloy is utilized in the manufacturing of pipes, radiation shielding, and specialty industrial components requiring thermal stability and strong adhesion.

Tin Lead Alloy Solder remains one of the most reliable and versatile joining materials used across electronics, aerospace, and precision manufacturing. Composed mainly of tin (Sn) and lead (Pb), it offers excellent wettability, strong mechanical bonding, and stable electrical conductivity. This article provides a comprehensive overview of Tin Lead solders, including eutectic and non-eutectic compositions such as Sn63Pb37 and Sn60Pb40, their physical and chemical properties, manufacturing methods, and global standards (ASTM B32, J-STD-006).

Different product forms—solder wire, bar, paste, foil, ribbon, and sheet—are examined in detail, highlighting their specific applications from PCB assembly and wave soldering to semiconductor packaging and hermetic sealing. The paper also discusses environmental regulations, handling safety, and selection criteria for choosing the right alloy for each process. Despite increasing adoption of lead-free alternatives, Tin-Lead solder continues to play an essential role in high-reliability fields where consistency, ductility, and proven long-term performance are indispensable.

Tin-Lead Alloy Solder has been one of the most important joining materials in the history of electronics manufacturing. Known for its excellent wettability, reliable bonding strength, and stable performance, this alloy remains a cornerstone in various industries—especially where proven reliability outweighs the need for lead-free compliance.

Soldering refers to the process of joining two or more metal surfaces by melting a filler metal (the solder) between them. Among all available solder types, Tin-Lead (Sn-Pb) alloys have been dominant for decades due to their ideal combination of melting temperature, ductility, and electrical conductivity.

Common compositions include:

Sn60Pb40 (60/40) – General purpose solder.

Sn63Pb37 (63/37) – Eutectic solder with single melting point (183 °C).

Sn50Pb50 (50/50) – For higher mechanical strength, used in plumbing or heavy joints.

Even though lead-free solders are now mandated in many consumer applications (due to RoHS and REACH regulations), Tin-Lead solder remains indispensable in aerospace, military, medical, and R&D fields where long-term reliability is crucial.

Tin-Lead solder consists mainly of tin (Sn) and lead (Pb) in varying ratios. Tin improves wetting and oxidation resistance, while lead lowers melting temperature and enhances fluidity.

Common Compositions:

| Alloy Type | Tin (%) | Lead (%) | Melting Point (°C) | Notes |

|---|---|---|---|---|

| Sn63Pb37 | 63 | 37 | 183 (eutectic) | Single-phase transition, best for PCB soldering |

| Sn60Pb40 | 60 | 40 | 183–190 | Widely used in electronic assembly |

| Sn50Pb50 | 50 | 50 | 183–215 | Stronger joints, slower flow |

| Sn40Pb60 | 40 | 60 | 183–238 | For plumbing, thick conductors |

| Sn30Pb70 | 30 | 70 | 255 | High-temperature or mechanical use |

Eutectic vs. Non-Eutectic:

Eutectic 63/37 solder melts and solidifies at a single temperature (183 °C), ensuring smooth joints with minimal plasticity.

Non-eutectic solders (like 60/40) have a melting range, solidifying gradually and reducing thermal shock.

| Property | Typical Value (Sn63Pb37) | Description |

|---|---|---|

| Density | 8.4 g/cm³ | Heavier than lead-free alternatives |

| Electrical Resistivity | 14 µΩ·cm | Good conductivity for circuit applications |

| Thermal Conductivity | 50 W/m·K | Efficient heat transfer |

| Tensile Strength | 40 MPa | Sufficient for most electronic joints |

| Elongation | 40% | Ductile and shock-resistant |

| Surface Tension | 450 mN/m | Ensures excellent spreading on copper |

Chemically, Tin-Lead solder is stable at room temperature but gradually oxidizes in air. Tin forms a protective oxide layer, while lead prevents excessive oxidation. This balance makes it superior for clean and uniform wetting.

Producing Tin-Lead solder involves precise alloying and quality control:

Raw Material Selection

High-purity tin (≥ 99.9%) and lead (≥ 99.9%) are used. Impurities like Fe, Al, Cu, and Zn must be below 0.001%.

Alloying

Tin and lead are melted in a controlled furnace. Continuous stirring ensures homogeneous mixing.

Casting

The molten alloy is cast into billets or bars.

Shaping

The billets are extruded or drawn into wires, rods, or sheets depending on end use.

Flux Core Filling (for solder wire)

Rosin or no-clean flux is injected into the hollow wire core.

Quality Inspection

According to ASTM B32 and J-STD-006, testing includes composition, appearance, flux content, and melting range.

Tin Lead Alloy Solder is manufactured in multiple physical forms to suit different soldering techniques and equipment. Each form—wire, bar, sheet, foil, ribbon, paste, or ball—has distinct features optimized for particular use cases.

Overview:

Tin Lead Solder Wire is the most common form used in hand soldering and rework operations. It consists of a solid or flux-core alloy wire, typically ranging from 0.3 mm to 3.0 mm in diameter.

Core Types:

Rosin Core (RMA, RA): Traditional electronic-grade flux; suitable for clean surfaces.

No-Clean Flux Core: Leaves minimal residue, eliminating post-solder cleaning.

Water-Soluble Core: Allows easy cleaning with water, preferred in cleanroom environments.

Applications:

Printed circuit board (PCB) assembly and repair.

Component pin and wire tinning.

Connector and cable terminations.

Audio, sensor, and precision device assembly.

Advantages:

Easy to handle and store.

Excellent flow and wetting on copper and tin-plated surfaces.

Consistent diameter for controlled solder feed.

Popular Compositions:

Sn60Pb40 (general purpose)

Sn63Pb37 (eutectic, precision electronics)

Overview:

Solder Bars are cast rectangular rods used in wave soldering and dip soldering processes. Bars are typically sized around 380 × 20 × 10 mm, weighing about 0.5–1.0 kg each.

Applications:

Wave soldering baths in PCB assembly lines.

Dip soldering of large connectors or terminals.

Coating of wire ends and lugs in industrial assembly.

Advantages:

Suitable for large-scale and automated soldering.

Stable alloy composition for consistent bath temperature.

Easy to replenish and control solder level during production.

Special Grades:

High Purity Electronic Grade: For sensitive microelectronic applications.

Industrial Grade: For cable harnesses, mechanical assemblies, and repair.

Usage Tip:

To maintain solder quality, regularly remove oxides (dross) from the solder pot using skimming tools or chemical dross removers.

Overview:

Tin Lead Alloy Sheet, Foil, and Ribbon are flat, flexible forms of solder designed for preforms, microjoining, and metallization processes.

Thickness ranges from 0.02 mm (foil) up to 3 mm (sheet), with ribbons often wound on reels for automation.

Applications:

Semiconductor packaging and die attachment.

Shielding and heat sink bonding.

Hermetic sealing in sensors and vacuum devices.

Thermal compression bonding of optical and microwave components.

Jewelry and decorative metal joining.

Advantages:

Uniform thickness ensures precise solder volume.

Ideal for vacuum or inert-atmosphere soldering.

Allows bonding without excessive flux residue.

Excellent wetting on gold, copper, Kovar, and nickel-plated substrates.

Example Compositions:

Sn63Pb37 Foil: For eutectic sealing applications.

Sn50Pb50 Ribbon: For thermal bonding and optical assemblies.

Customization:

Suppliers can provide die-cut preforms—small discs, washers, or frames—ready for pick-and-place soldering or automated bonding.

Overview:

Solder Paste is a semi-solid blend of fine Sn-Pb alloy powder (Type 3–5 particle size, typically 25–45 μm) suspended in flux medium.

Applications:

Surface Mount Technology (SMT) reflow soldering.

Chip attachment for ICs, LEDs, and MEMS devices.

Microelectronic die bonding.

Advantages:

High printing accuracy with stencil or screen.

Consistent paste rheology for automated production.

Eutectic Sn63Pb37 paste ensures sharp melting and strong joints.

Storage:

Refrigerate at 0–10 °C and use within 6 months for stable performance.

Overview:

Solder Balls are precisely formed micro-spheres of Sn-Pb alloy used in Ball Grid Array (BGA) and Chip Scale Packaging (CSP) processes.

Applications:

Semiconductor interconnects.

Flip-chip packaging.

Wafer bumping and repair operations.

Advantages:

Controlled size (0.1–0.8 mm) for uniform solder joints.

Compatible with automated pick-and-place systems.

Eutectic composition provides repeatable reflow behavior.

Overview:

Fine Tin-Lead powder is used in additive manufacturing of electronic materials, solder paste production, and metal coating applications.

Applications:

Reflow paste formulation.

Conductive adhesive fillers.

Powder metallurgy experiments.

Typical Composition: Sn63Pb37 or Sn60Pb40

Particle Size: 20–45 µm, gas-atomized for spherical uniformity.

Solder Rods: For manual torch soldering and cable terminations.

Solder Rings/Preforms: Pre-shaped rings used in gas-tight sealing.

Solder Pellets: Convenient for batch melting and controlled alloy addition.

These forms cater to diverse manufacturing processes—from large-scale production to precision microjoining.

During soldering:

The solder is heated until molten.

Flux removes surface oxides.

The liquid alloy wets the base metal.

Upon cooling, it solidifies, creating a metallurgical bond.

Eutectic Tin-Lead solder transitions directly from liquid to solid—no plastic phase—reducing the chance of cold joints.

Non-eutectic compositions solidify gradually, suitable for joints requiring better thermal stress absorption.

Tin Lead Alloy Solder Wire and Paste dominate electronics production due to their excellent flow characteristics and reliability.

Solder Wire: Used in manual soldering, repair, and prototype builds.

Solder Paste: Applied in SMT reflow processes for IC and resistor placement.

Solder Bar: Maintains solder baths in wave soldering systems.

These alloys ensure low-resistance electrical paths, smooth fillets, and long-term mechanical stability.

High reliability is mandatory in aerospace electronics where thermal cycles and vibration are severe.

Sn63Pb37 and Sn62Pb36Ag2 are common due to:

Excellent fatigue resistance.

Controlled solidification without micro-cracking.

Proven performance under extreme temperature swings.

Applications include:

Satellite instrumentation.

Avionics boards.

Communication systems.

Used in:

Sensors and control units.

PCB assemblies for engine management systems.

Wiring harness soldering and power modules.

Tin Lead Bars and Wires are chosen for reworkability and high ductility, tolerating vibration and thermal shock.

Tin Lead Foil and Ribbon play key roles in:

Die bonding.

Hermetic sealing.

Thermal interface layers in photonics.

Their uniform thickness allows consistent solder volume and improved bonding accuracy.

Solder Bars and Rods are common for large connectors, transformers, and busbars.

Advantages:

Excellent conductivity.

Low thermal stress.

Ability to fill wide gaps in mechanical joints.

Tin Lead Sheets and Ribbons are used for:

Stained glass soldering.

Artistic metal joining.

Jewelry repair and ornamentation.

The low melting temperature prevents color distortion of decorative metals.

Researchers use Tin Lead Alloy Foils and Pellets for experimental alloying, joining, or deposition.

They are ideal for:

Material testing.

Microelectronics development.

Thermal and wetting experiments.

Solder Wire and Bars remain indispensable in maintenance operations:

Repairing PCBs, connectors, and terminals.

Rework on non-RoHS systems.

Prototyping and academic use.

Before RoHS, leaded solder was widely used for plumbing joints, pewter work, and decorative metal bonding.

Today, it remains in restoration and heritage metalcraft applications where authenticity is critical.

Excellent wetting and flow behavior.

Smooth, shiny solder joints.

Good electrical and thermal performance.

Readily available and cost-effective.

Easily reworked and repaired.

Contains toxic lead; requires handling precautions.

Restricted by RoHS, REACH, and WEEE.

Slightly heavier and less environmentally friendly.

Requires fume extraction or PPE during soldering.

Storage Temperature: 10 – 30 °C; avoid humidity.

Avoid oxidation: Keep sealed in airtight containers.

Safety: Always work in a well-ventilated area; use gloves and fume extractors.

Waste Disposal: Collect lead-containing residues separately. Dispose through certified recycling facilities.

Repeated exposure to lead fumes or dust can be hazardous. Follow local regulations such as OSHA 1910.1025 for lead exposure.

| Standard | Description |

|---|---|

| ASTM B32 | Composition, form, and test method for solder metals. |

| J-STD-006 | Requirements for electronic grade solder alloys and fluxes. |

| IPC-TM-650 | Test methods for solderability and wetting balance. |

| ISO 9453 | International alloy classification system. |

Testing parameters:

Melting temperature range (DSC).

Surface smoothness and color.

Impurity analysis (ICP-OES).

Wetting time and spread ratio.

| Application | Recommended Alloy | Notes |

|---|---|---|

| General electronics | Sn60Pb40 or Sn63Pb37 | Balanced performance |

| Precision circuits | Sn63Pb37 (eutectic) | Sharp melting point |

| High mechanical load | Sn50Pb50 | Higher lead improves strength |

| High-temp conditions | Sn30Pb70 | Withstands > 230 °C |

| Hobby or DIY | Sn60Pb40 | Easy to use |

When selecting solder, consider:

Operating temperature.

Joint size and metal type.

Required mechanical flexibility.

Regulatory compliance.

| Property | Sn-Pb Alloy | Lead-Free (Sn-Ag-Cu) |

|---|---|---|

| Melting Point | 183 °C | 217 – 227 °C |

| Wetting Ability | Excellent | Moderate |

| Mechanical Strength | Good | Higher but brittle |

| Cost | Lower | Higher |

| Reworkability | Easy | More difficult |

| Regulation | Restricted | Compliant |

While lead-free solders are essential for consumer goods, Tin-Lead solder continues to dominate in high-reliability and R&D sectors, where proven long-term stability is more critical than regulation compliance.

The Restriction of Hazardous Substances (RoHS) directive limits lead to 0.1% maximum in consumer electronics. However, exemptions exist for:

Aerospace and defense applications.

Medical diagnostic and monitoring equipment.

Industrial instrumentation.

Suppliers should provide:

Certificate of Analysis (CoA).

Material Safety Data Sheet (SDS).

RoHS/REACH declarations indicating exemption category.

| Product Type | Typical Size | Packaging |

|---|---|---|

| Solder Bar | 8 × 6 × 380 mm | 25 kg carton |

| Solder Wire | Ø0.5 – 3.0 mm | 500 g spool |

| Solder Paste | Type 3–5 particle size | 500 g jar or syringe |

| Solder Ball | 0.1–0.8 mm | Vacuum sealed bag |

Suppliers usually vacuum-seal solder to prevent oxidation and include desiccant packs for long-term storage.

Although the world is moving toward lead-free systems, Tin-Lead solder remains vital in areas demanding exceptional reliability. Future trends include:

Hybrid Sn-Pb-Ag systems for better fatigue resistance.

Nanostructured Sn-Pb solder pastes with enhanced wetting.

AI-based inspection tools for solder joint quality analysis.

Environmentally responsible recycling and closed-loop recovery.

As technology evolves, traditional Sn-Pb solder continues to serve as the benchmark against which newer formulations are judged.

Tin-Lead Alloy Solder has been the foundation of electronic interconnection for decades. Its eutectic 63/37 formulation ensures precise melting, strong joints, and excellent conductivity. While environmental regulations now restrict its widespread use, it remains unmatched in stability, reworkability, and proven reliability for aerospace, defense, and R&D sectors.

Choosing the right composition, applying correct soldering techniques, and adhering to safety practices ensures high-performance joints and long service life.

What is Tin-Lead Alloy Solder made of?

It’s primarily composed of tin (Sn) and lead (Pb) in varying ratios, typically 60/40 or 63/37 by weight.

What is eutectic solder?

Eutectic solder, such as Sn63Pb37, melts and solidifies at a single temperature (183 °C), giving precise control and smooth joints.

What is the melting point of Tin-Lead solder?

Between 183 °C and 250 °C depending on composition. The 63/37 alloy melts exactly at 183 °C.

Why is lead added to solder?

Lead lowers the melting point, improves flow, and enhances mechanical strength.

Is Tin-Lead solder banned?

Not completely. It’s restricted in consumer products under RoHS but allowed in aerospace, defense, and medical applications.

Is Tin-Lead solder safe to use?

Yes, when handled properly with adequate ventilation and protective gear.

Can Tin-Lead solder be used with copper?

Absolutely. It wets copper surfaces excellently, forming strong intermetallic bonds.

What flux is best for Tin-Lead solder?

Rosin-based or no-clean fluxes are ideal for electronics applications.

Can I mix leaded and lead-free solder?

It’s not recommended. Mixing alters melting behavior and may weaken joints.

How long does Tin-Lead solder last in storage?

Typically 2–3 years if stored in a dry, sealed container below 30 °C.

What is the density of 60/40 solder?

About 8.5 g/cm³.

Can Tin-Lead solder be reused?

Yes, but re-melting may introduce oxide contamination; proper fluxing is essential.

How do I clean solder joints?

Use isopropyl alcohol (IPA) or specialized flux remover to remove residues.

Why do solder joints turn dull?

Overheating or oxidation can cause dull, grainy joints. Use correct temperature and clean tips.

What causes solder bridging?

Excess solder or flux, too high temperature, or improper tip size.

Can Tin-Lead solder be used in high-temperature electronics?

Yes, but for continuous operation above 150 °C, high-lead (> 85%) alloys are better.

How to identify poor solder joints?

Look for cracks, voids, dull surfaces, or incomplete wetting.

Is Tin-Lead solder conductive?

Yes, it offers low electrical resistance ideal for PCBs.

Does Tin-Lead solder oxidize?

Slightly, especially in humid air. Store properly to prevent oxidation.

What are common soldering temperatures?

Typically 230–260 °C depending on the alloy and component.

Is Tin-Lead solder recyclable?

Yes. Scrap solder can be reclaimed and refined for reuse.

What is the best Tin-Lead solder for rework?

Sn63Pb37 eutectic type for its precise melting point.

Can Tin-Lead solder be used in medical devices?

Only for exempted applications where reliability outweighs RoHS restriction.

Is Tin-Lead solder suitable for SMT?

Yes. Sn63Pb37 solder paste remains standard in high-reliability SMT reflow processes.

Where can I buy high-purity Tin-Lead solder?

From specialized material suppliers offering certified alloys that meet ASTM B32 and J-STD-006 standards.