Menu

If you have limited space or power in your system, micro-electronic sources are a great choice. We have a wide range of smaller sources that are designed to be compact and efficient, just like our larger evaporation sources. Most of the sources in this section are a little less than 2.00 inches long.

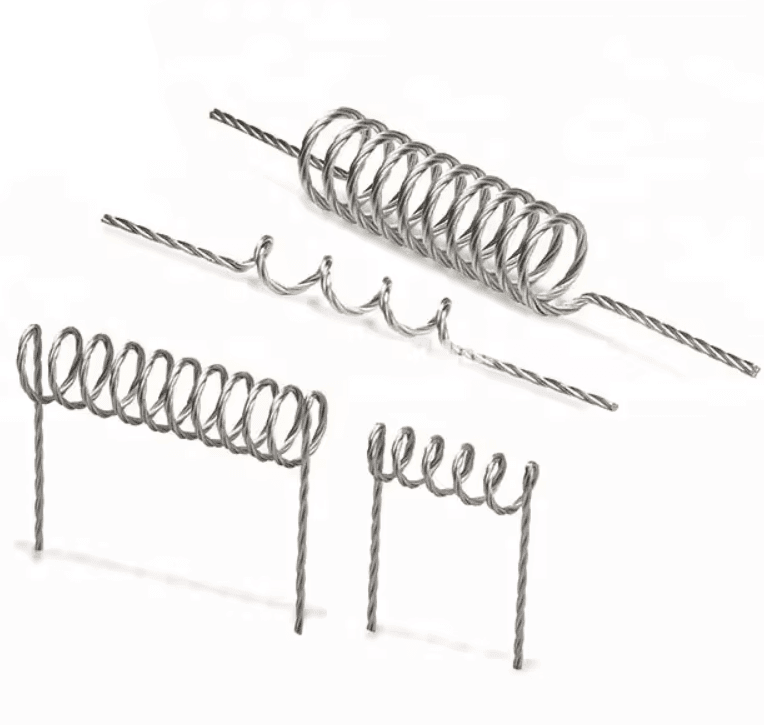

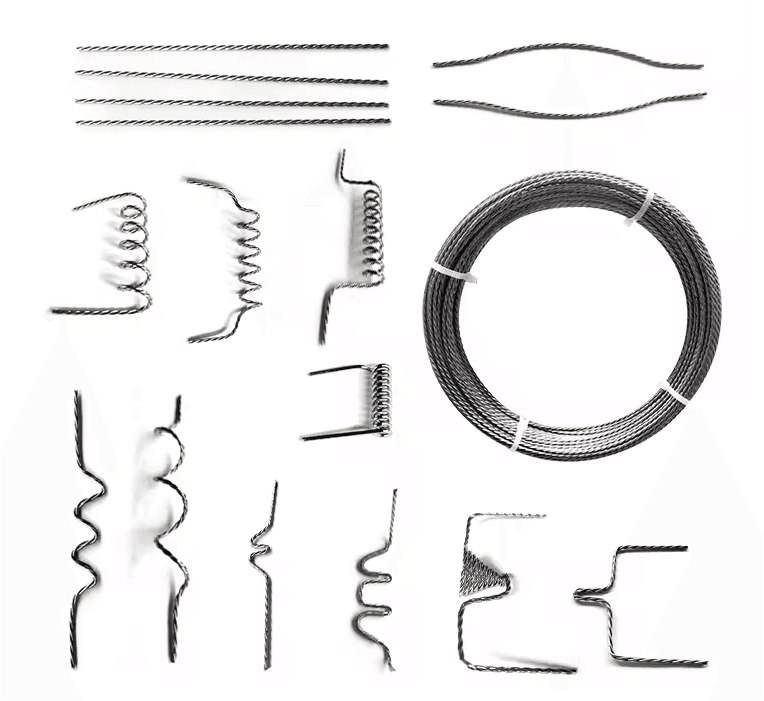

If you’re looking for a cost-effective, user-friendly thermal evaporation source that you can use for a short period of time, filament sources are a great choice. They’re commonly used for flash evaporation with wires or canes. Filament sources are available in various configurations and can be single or multi-stranded.

These rods are specifically designed to provide you with the best results when it comes to adhesion layers. And if you prefer tungsten rod sources wrapped with tungsten wire, we’ve got you covered there too. We offer a wide variety of options to ensure you have exactly what you need for your project.

Basket heaters are a convenient option for loading material directly into the basket without the need for a crucible. These heaters are typically made from tungsten wires, either single or multi-stranded. In addition, there are also alumina coated basket heaters available for materials that can alloy with refractory metals.

When it comes to depositing different materials, crucible heaters with crucibles are a great choice. They allow you to load more material compared to a regular boat source. You can choose from basket heaters made from stranded tungsten wire or shielded crucible heaters that heat up more efficiently.

We offer a wide range of crucibles for both thermal and e-beam evaporation. Our crucibles are available in various materials to suit your specific needs. Additionally, we also have HTE (high temperature evaporation) and LTE (low temperature evaporation) crucibles for thermal evaporation sources that require extreme temperature conditions.

Boats come in a wide range of sizes, dimensions, and materials. You can find boats in different lengths, widths, and thicknesses. Additionally, there are various shapes and configurations to choose from.

Box furnaces come in different designs to suit your needs. These furnaces are specifically designed to prevent splattering when heating certain materials. The baffles in the furnaces block the direct view between the material being heated and the surface it is resting on.

Alumina-coated evaporation sources have been created as a substitute for alumina crucibles in certain specialized applications.

In the realm of materials science and thin film deposition, evaporation sources are indispensable tools that play a crucial role in various applications. From semiconductors and optics to solar cells and medical devices, these sources are utilized to deposit highly pure thin films onto substrates through the process of physical vapor deposition (PVD).

But how do evaporation sources actually work? And what are their key applications? In this comprehensive guide, we delve into the intricate workings of evaporation sources, exploring the principles behind their operation and shedding light on their wide-ranging applications in industries across the board.

From resistive and electron beam sources to thermal and sputtering sources, we examine the different types of evaporation sources available, delving into their unique characteristics and advantages. Furthermore, we explore the various factors that influence source choice, such as material compatibility, film thickness requirements, and deposition rate.

Whether you’re a researcher, engineer, or simply curious about the world of thin film deposition, this ultimate guide will equip you with the knowledge needed to navigate the fascinating realm of evaporation sources and their applications.

Evaporation sources work by transforming solid materials into vapor phase, which are then condensed onto a substrate to form a thin film. This process involves heating the source material to its evaporation temperature, typically achieved through resistive, electron beam, or thermal means.

Resistive evaporation sources utilize a resistive heating element, such as a tungsten filament, to generate heat and vaporize the source material. The filament is heated to a high temperature, causing the material to sublimate and form a vapor. This vapor then travels towards the substrate, where it condenses and forms a thin film.

Electron beam evaporation sources employ a high-energy electron beam to heat the source material. A high voltage is applied to an electron gun, which emits a focused beam of electrons. These electrons bombard the source material, causing it to heat up and evaporate. The vaporized material then travels towards the substrate, where it condenses and forms a thin film.

Thermal evaporation sources rely on resistive heating or electron beam evaporation to heat the material, similar to their respective counterparts. The key difference lies in the design of the evaporation source. Thermal sources are typically designed with a crucible or boat, which holds the source material. The crucible is heated, causing the material to vaporize and form a thin film on the substrate.

Evaporation sources come in various types, each with its own unique characteristics and advantages. Here are some of the most commonly used types:

1. Resistive evaporation sources: These sources are widely used due to their simplicity and cost-effectiveness. They are suitable for a wide range of materials and can achieve high deposition rates. However, they may not be suitable for materials with high melting points.

2. Electron beam evaporation sources: Electron beam sources offer precise control over the evaporation process and can achieve high deposition rates. They are ideal for materials with high melting points and enable the deposition of highly adherent and dense films. However, they tend to be more expensive and require complex equipment.

3. Thermal evaporation sources: Thermal sources are versatile and can accommodate a wide range of materials. They are relatively simple to operate and cost-effective. However, they may not achieve the same level of control and uniformity as electron beam sources.

4. Sputtering sources: Although not strictly evaporation sources, sputtering sources are worth mentioning as they are commonly used in thin film deposition processes. Sputtering involves bombarding a target material with high-energy ions, causing atoms to be ejected and deposited onto a substrate. This process offers excellent film adhesion and can deposit a wide range of materials.

The semiconductor industry heavily relies on evaporation sources for various applications. One of the key uses is in the deposition of metal contacts and interconnects in integrated circuits. Evaporation sources enable precise and controlled deposition of metals such as aluminum, copper, and gold, ensuring optimal electrical conductivity and reliability.

Evaporation sources are also instrumental in the production of semiconductor devices, such as diodes and transistors. Through precise control of the deposition process, evaporation sources allow for the creation of thin films with specific electrical properties, ensuring optimal device performance.

In addition, evaporation sources are used in the fabrication of photovoltaic devices, such as solar cells. These sources enable the deposition of thin films of semiconductor materials, such as silicon and cadmium telluride, which are essential for the conversion of sunlight into electricity.

Evaporation sources are widely employed in thin film deposition processes, where thin layers of materials are deposited onto substrates for various applications. Such processes are commonly used in the manufacturing of electronic devices, optical coatings, and medical devices, among others.

One of the key advantages of evaporation sources in thin film deposition is their ability to achieve high purity films. By utilizing high-quality source materials and carefully controlling the deposition parameters, evaporation sources can deposit films with minimal impurities, ensuring optimal device performance and reliability.

Evaporation sources also offer excellent control over film thickness. By adjusting the deposition time and rate, precise control of the film thickness can be achieved, allowing for the creation of thin films with specific properties and functionalities.

Organic light-emitting diodes (OLEDs) are a promising technology for displays and lighting applications. Evaporation sources play a crucial role in the manufacturing of OLED devices, particularly in the deposition of organic layers.

OLED devices consist of multiple organic layers, each with specific electrical and optical properties. Evaporation sources enable the deposition of these organic layers by heating the organic materials to their evaporation temperature and allowing them to condense onto the substrate.

The use of evaporation sources in OLED manufacturing offers precise control over layer thickness and composition, ensuring uniformity and optimal device performance. Additionally, the high purity of the deposited films contributes to the longevity and efficiency of OLED devices.

Different types of solar cells require different semiconductor materials, such as silicon, cadmium telluride, and copper indium gallium selenide. Evaporation sources enable the deposition of these materials onto the substrate, forming the active layer of the solar cell.

The use of evaporation sources in solar cell production ensures precise control over the thickness and composition of the semiconductor layer, optimizing the absorption of sunlight and enhancing the efficiency of the solar cell. Additionally, the high purity of the deposited films contributes to the long-term stability and reliability of the solar cell.

Evaporation sources offer several advantages that make them a popular choice in thin film deposition processes. Some of the key advantages include:

However, evaporation sources also have some disadvantages that should be considered:

The purity level of evaporation materials is a critical factor in the quality of the thin films produced. Purity levels are typically expressed in percentages, with high-purity materials having fewer impurities. These levels can range from 99.9% to 99.99999%, with the required purity depending on the application and the performance requirements of the thin film.

Impurities in the evaporation material can lead to defects, contamination, and reduced performance in the deposited thin film. Therefore, ensuring the appropriate purity level is essential for achieving the desired properties and functionality of the thin film.

Techniques for ensuring high purity levels in evaporation materials include advanced purification methods, such as zone refining, chemical vapor deposition, and electron beam melting. Additionally, careful handling and storage of the materials can help maintain their purity throughout the deposition process.

Evaporation materials come in various shapes, including chunks, pellets, wires, rods, and granules. The shape of the material can affect the evaporation rate and the uniformity of the deposited film.

Manufacturers often provide these materials in specific shapes to accommodate different types of evaporation equipment and processes. For example, wire-shaped materials may be suitable for use in thermal evaporation systems, while pellets or chunks may be better suited for e-beam evaporation.

The choice of material shape is influenced by factors such as the desired deposition rate, the size and geometry of the evaporation source, and the specific requirements of the thin film application. By selecting the appropriate material shape, engineers can optimize the evaporation process and achieve the desired thin film properties.

This comprehensive resource provides information on the properties, applications, and handling of various evaporation materials. It serves as a reference for engineers and technicians to select the appropriate material for their specific deposition needs.

The important factors you need to consider when investing in evaporation materials:

By referencing the evaporation material guide, you can make informed decisions about the most suitable materials for their thin film deposition projects, ensuring the successful fabrication of high-quality thin films.

Evaporation materials are the foundation of thin film deposition processes, playing a crucial role in the advancement of various industries, from electronics to optics. Understanding the different types of evaporation materials, the associated deposition processes, and the factors that influence their performance is essential for engineers and researchers working in the field of vacuum engineering and materials science.

By exploring the intricacies of evaporation materials, including their composition, purity, shapes, and deposition characteristics, users can optimize the thin film deposition process and develop innovative solutions that push the boundaries of technology. Continued research and development in this field will undoubtedly lead to further advancements in the production of high-performance thin films and the expansion of their applications.