Menu

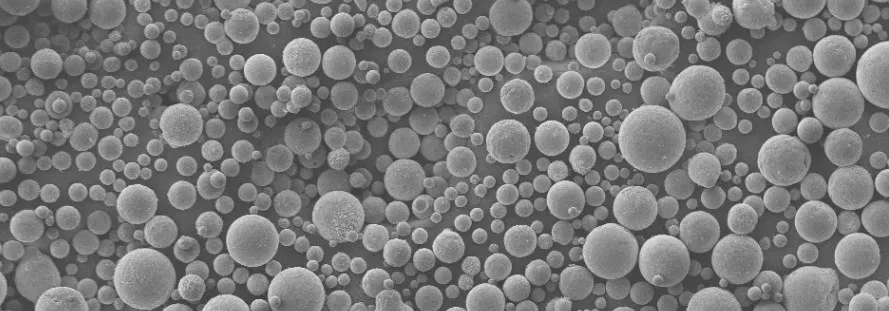

MetalsTek Engineering specializes in the manufacturing and supply of a diverse range of metallic powders and compounds, including nano-scale APS and spherical powders designed for additive manufacturing. These powders are extensively utilized in 3D printing, thermal spraying coatings (such as Plasma Spraying, HVOF Spraying, Arc Spraying, and Flame Combustion Spraying), and various other applications.

Innovation is key in the dynamic world of modern manufacturing. MetalsTek Engineering is at the forefront of this innovation, specializing in producing and supplying an extensive range of metallic powders and compounds. From nano-scale APS to spherical powders designed for additive manufacturing, we offer high-quality materials tailored to meet the rigorous demands of contemporary industry applications.

MetalsTek Engineering is renowned for its precision in manufacturing advanced metallic powders that serve many industrial applications. Our portfolio includes nano-scale APS (Average Particle Size) and spherical powders, particularly crucial for additive manufacturing processes. These high-purity powders are meticulously engineered to ensure optimal performance, making them ideal for 3D printing, printing, spraying, printing, and more.

The versatility of our metallic powders is one of their standout features. Here’s a closer look at how these powders are transforming various industries:

1. Additive Manufacturing (3D PrintinPrintingspherical printing powders are highly sought after in additive manufacturing. Their uniform size and shape contribute to creating precise and high-quality 3D-printed components. These powders enable manufacturers to produce complex geometries that would be challenging, if not impossible, to achieve using traditional methods.

2. Thermal Spraying Coatings:

Thermal spraying is when melted or heated materials are sprayed onto a surface to create a coating. Our powders are extensively used in various thermal spraying techniques, such as:

These coatings are essential in various sectors, including aerospace, automotive, and energy, providing enhanced surface properties such as corrosion resistance, wear resistance, and thermal insulation.

3. Advanced Material Development:

Beyond additive manufacturing and thermal spraying, our powders are instrumental in research and development. Universities, laboratories, and high-tech industries utilize these materials to innovate and develop new products and technologies. Our powders’ high purity and consistent quality ensure reliable and reproducible results, fostering advancements in material science and engineering.

At MetalsTek Engineering, quality is paramount. Our state-of-the-art production facilities and stringent quality control measures ensure that every powder batch meets the highest standards. Additionally, we offer customization options to cater to specific customer needs, whether adjusting particle size distribution or tailoring chemical compositions. This flexibility allows us to serve a diverse clientele, from large-scale manufacturers to specialized research institutions.

MetalsTek understands the critical importance of timely delivery and efficient communication. We are dedicated to addressing common pain points in the industry, such as delayed shipments and inefficient supplier interactions. By maintaining transparent communication and robust logistics, MetalsTek ensures that its clients receive their orders promptly and accurately, minimizing downtime and enhancing productivity.

In an era where advanced materials drive innovation, MetalsTek Engineering stands out as a leader in the manufacturing and supply of high-quality metallic powders. Our powder products offer unparalleled performance and reliability, whether for cutting-edge 3D printing applications or robust thermal spraying coatings. As industries continue to evolve, we remain committed to pushing the boundaries of what’s possible, delivering materials that empower businesses to achieve new heights of excellence.

For more information or to discuss your specific material needs, please visit our website at www.metalstek.com or sales@metalstek.com.