Menu

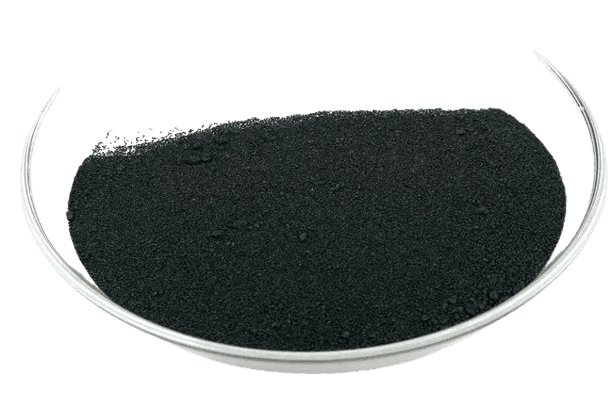

MetalsTek Engineering is a trusted supplier of Cobalt Powders. We hold various cobalt powders, including Cobalt Spherical Powder, Nano Cobalt Powder, Micron Cobalt Powder, Cobalt Powder for Diamond Tools, and more.

Material: Cobalt, Co

Purity: 99% Min

Densities: 5g/cc Bulk Density, 6.0g/cc Tap Density

Particle Size: 15~150μm

Flow Rate: ≤12.0s/50g

| Co | Bal. | Mo | <0.003 | Si | <0.002 |

| Ta | <0.05 | Ni | <0.002 | Cr | <0.002 |

| W | <0.005 | Al | <0.002 | Ti | <0.002 |

| Fe | <0.005 | Mn | <0.002 | Cu | <0.001 |

Spherical Cobalt Powder Applications

Material: Cobalt, Co

Purity: 99.9% Min.

Flow Densities: 0.4-0.75 g/cm3

Particle Size: FSSS- 1.3-1.7μm

Compositions(%): Co:99.9 Ni:0.005 Cu:0.002 Fe:0.005 Pb:0.005

Material: Cobalt, CAS # 7440-48-4

Purity: >99.9%

Bulk Density: 0.19-1.23 g/cc

Particle Size(APS): 50~300nm

Specific Surface Area: 40.3-10.3 m2/g

Material: Cobalt, CAS # 7440-48-4

Purity: >99.9%

Particle Size(APS): 40~50μm

Main Applications: Cemented Carbide, Diamond Tools, Superalloys, Magnetic Materials

Cobalt Powder is utilized in various applications, including producing alloys for lithium-ion batteries and magnetic, wear-resistant, and high-strength products. It is also used in electroplating due to its hardness and in the manufacture of lithium-ion batteries due to its high strength and wear resistance. Cobalt Powder is a ferromagnetic metal and is used primarily in the production of magnetic and high-strength superalloys. Due to its wear resistance, strength, and durability, it is also employed in 3D printing for biomedical, aerospace, and automotive applications. Additionally, Cobalt Powder is used in surface coating deposition techniques to make surfaces harder and more resilient against wear and corrosion.

Cobalt Powder is commonly used in the following applications:

1. Metal Additive Manufacturing: Cobalt Powder is utilized in metal additive manufacturing processes such as selective laser melting (SLM) and electron beam melting (EBM) to produce complex metal parts with high precision and mechanical properties. It is often alloyed with other metals such as chromium, nickel, and tungsten to enhance specific characteristics like strength and corrosion resistance.

2. Hardfacing and Thermal Spraying: Cobalt Powder is employed in hardfacing applications to improve metal surfaces’ wear resistance and durability. It is sprayed onto surfaces using thermal spraying to create a protective coating that can withstand abrasion, erosion, and corrosion in harsh environments.

3. Catalysis: Cobalt Powder catalyzes various chemical processes, including hydrogenation, oxidation, and Fischer-Tropsch synthesis. It facilitates chemical reactions by providing a surface for reactants to interact and form desired products.

4. Battery Materials: Cobalt Powder is a crucial component in the cathode materials of lithium-ion batteries used in electric vehicles, consumer electronics, and energy storage systems. It helps improve battery performance, energy density, and stability.

5. Diamond Tools: Cobalt Powder is a binder material that produces diamond tools such as saw blades, grinding wheels, and drill bits. It helps hold the diamond abrasive particles together and enhances the tool’s cutting performance and lifespan.

6. Magnetic Materials: Cobalt Powder is used for producers, including soft magnetic materials used in magnetic recording media and hard magnetic materials used in permanent magnets.

7. Chemical and Metallurgical Processes: Cobalt Powder is employed in various chemical and metallurgical processes, including metal injection molding, powder metallurgy, and metal surface treatment.

Our Cobalt Powders are clearly labeled externally to ensure efficient identification and quality control. To prevent any damage during storage or transportation, we take great care.