Menu

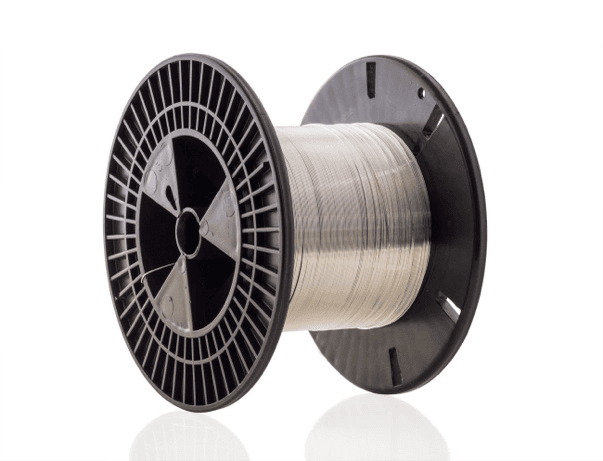

MetalsTek Engineering is a trusted supplier of Cobalt Wire. We can supply high-quality cobalt wire, rods, and bars competitively.

Material: Cobalt, CAS # 7440-48-4

Purity: 99%, 99.9%, 99.95%, 99.99%

Size: Wire – Diameter 0.05~3.00 mm * Length

Rod – Diameter 3.00~80mm * Length<2,000mm

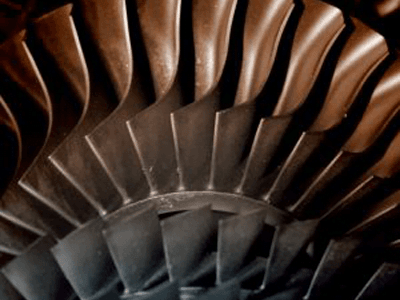

Material: HAYNES Alloy 188, UNS R30188

Composition: Co-Cr(20%~24%)-Ni(20%~24%)-W(13%~15%)-Fe(<3%)-C(<0.15%)

Properties: 9.14g/cc Density, 1,300°C M.P.

Feature: Oxidation Resistance Up to 1,095°C

Main Applications: Turbine Engines, Combustor Cans, Flame Holders, Liners

Synonym: Superimphy 90, Pyromet 90, Udimet 90

Material: Nickel Chromium Cobalt Alloy

Compositions: Ni-Cr(18%~21%)-Co(15%~21%)

Properties: 8.18g/cc Density, 1,370°C M.P.

Main Application: Aerospace Fasteners

Material: Nickel Iron Cobalt Alloy

Composition: Nickel(<29%)-Fe(<53%)-Co(<17%)

Properties: 8.16g/cc Density, 1450°C M.P.

Thermal Conductivity: 16.7 W/m•°C

Size: Tailored Size

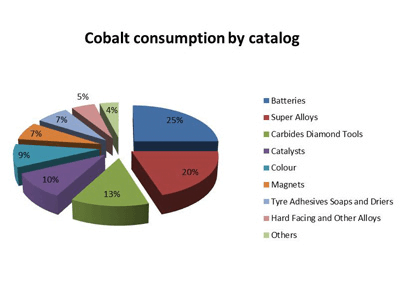

Cobalt Wire is a blue-silver metal commonly used in the production of magnets and in various applications such as mobile devices, batteries, and the medical industry. It is also utilized in the electronics sector. Cobalt Wire is available in multiple forms and sizes and is known for its high density, thermal conductivity, and electrical resistivity. The wire is used in different lengths and diameters for specific applications and is widely available for purchase from various suppliers.

Cobalt and cobalt alloy wires are distinguished by their unique properties, including high strength at elevated temperatures, excellent wear and corrosion resistance, and remarkable magnetic qualities. These attributes make them ideal for various industrial, aerospace, medical, and electronic applications. Here’s an overview of the critical applications of cobalt and cobalt alloy wires:

Cobalt and its alloys serve a broad spectrum of critical applications across various industries through their exceptional mechanical properties and resistance to wear, heat, and corrosion. Their versatility and durability under challenging conditions underscore their importance in modern technology and industrial applications.

Our Chromium Evaporation Materials are clearly labeled externally to ensure efficient identification and quality control. To prevent any damage during storage or transportation, we take great care.