Menu

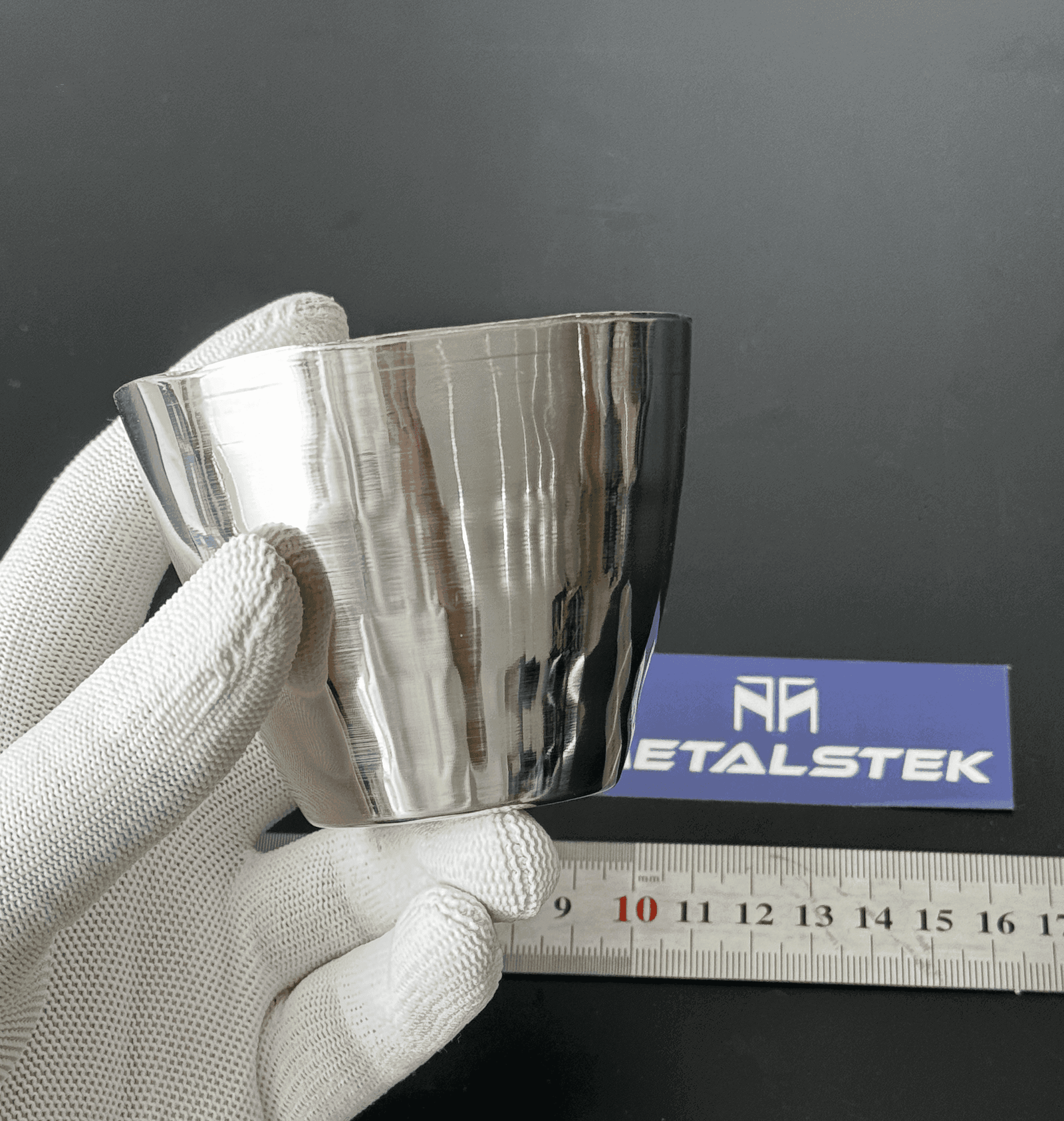

MetalsTek Engineering is a leading manufacturer and supplier of Platinum Crucible Molds and Boats. We can produce high-quality Platinum (Pt), Platinum Gold (Pt/Au), Platinum Iridium (Pt/Ir), and Platinum Rhodium (Pt/Rh) Crucible Molds and Boats with short lead times and competitive prices. Tailored Platinum Crucibles are available, including replacements for Perl-X®, Katanax®, Claisse®, Vulcan, Phoenix, Herzog, Linn®, Leco®, and more.

Material: Platinum Pt, Platinum Gold Pt/Au, Platinun Rhodium Pt/Rh, Platinum Iridium Pt/Ir

Composition: PtAu5, PtIr(5%~25%), PtRh(10%~30%)

Purity: Pt ≥ 99.95%, Au ≥ 99.99%, Ir ≥ 99.99%, Rh ≥ 99.99%

Capacity: 5mL~300mL, or Customized

| Code | Capacity (ml) | Diameter (mm) | Depth (mm) | Std. Form (g) | Rim Only Reinforced (g) | Base Only Reinforced (g) | Rim & Base Reinforced (g) | Std. Lid Only (g) |

| GCS2.5 | 2.5 | 12 | 15 | 3 | 4 | 4 | 5 | 2 | |

| GCS5 | 5 | 20 | 22 | 4 | 5 | 5 | 6 | 2 | |

| GCS8 | 8 | 25 | 24 | 6 | 7 | 7 | 8 | 2 | |

| GCS10 | 10 | 25 | 28 | 7 | 7.5 | 8 | 9 | 3 | |

| GCS15 | 15 | 30 | 31 | 11 | 12 | 13 | 14 | 4 | |

| GCS20 | 20 | 33 | 35 | 15 | 16 | 17 | 18 | 5 | |

| GCS25 | 25 | 36 | 34 | 19 | 20 | 21 | 23 | 5 | |

| GCS30 | 30 | 40 | 36 | 22 | 24 | 26 | 27 | 7 | |

| GCS35 | 35 | 41 | 38 | 25 | 26 | 27 | 32 | 7 | |

| GCS40 | 40 | 42 | 42 | 30 | 32 | 34 | 36 | 7 | |

| GCS50 | 50 | 45 | 44 | 38 | 40 | 42 | 45 | 8 | |

| GCS60 | 60 | 45 | 47 | 46 | 48 | 50 | 54 | 9 | |

| GCS70 | 70 | 49 | 53 | 50 | 52 | 54 | 63 | 12 | |

| GCS80 | 80 | 51 | 53 | 51 | 54 | 63 | 72 | 14 | |

| GCS90 | 90 | 54 | 57 | 52 | 59 | 71 | 81 | 15 | |

| GCS100 | 100 | 56 | 57 | 59 | 68 | 73 | 90 | 17 | |

| GCS110 | 110 | 56 | 60 | 68 | 71 | 81 | 95 | 19 | |

| GCS120 | 120 | 64 | 66 | 84 | 88 | 90 | 98 | 22 | |

| GCS150 | 150 | 65 | 69 | 100 | 104 | 107 | 114 | 27 | |

| GCS200 | 200 | 80 | 65 | 150 | 159 | 165 | 180 | 30 | |

| GCS250 | 250 | 81 | 73 | 175 | 179 | 183 | 190 | 32 | |

| GCS700 | 700 | 107 | 105 | 300 | 305 | 315 | 320 | 50 |

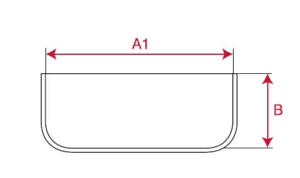

Material: Platinum Gold

Composition: PtAu5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%

Capacity: 1mL~10mL, or Customized

| Micro Pt Crucible | Capacity (mL) | A1 (mm) | D (mm) | B (mm) |

| 1 | 12 | 7.2 | 13 |

| 3 | 17 | 10 | 19 | |

| 5 | 20.5 | 12 | 22 | |

| 10 | 26 | 15.5 | 28 |

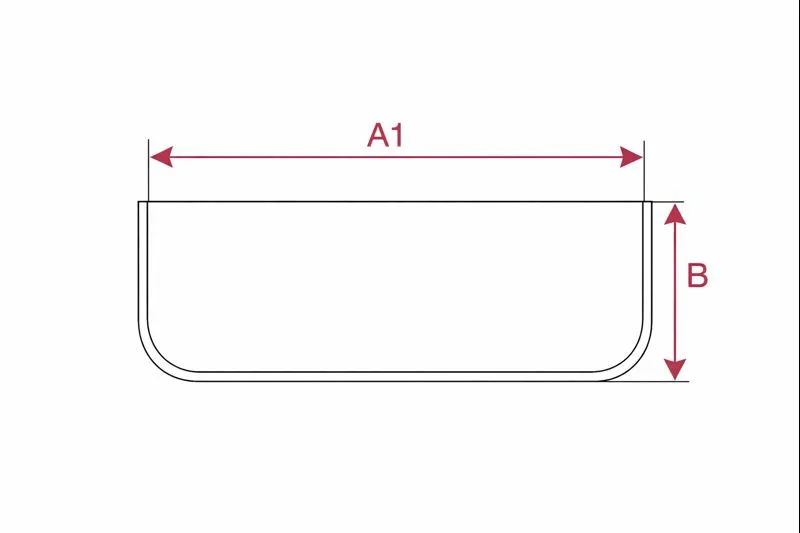

Material: Platinum Pt, Platinum Gold Pt/Au, Platinun Rhodium Pt/Rh, Platinum Iridium Pt/Ir

Composition: Pt, PtAu5, PtIr5, PtRh5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%, Ir ≥ 99.99%, Rh ≥ 99.99%

Capacity: 5mL~125mL, or Customized

Other: Reinforced Base and Rim Available

| DRAWING | Code | Capacity | B (mm) | A1 (mm) | Weight (g) | Reinforced Base and Rim Weight Range | Lid Weight (g) |

| PT9501 | 5ml | 20 | 26 | 4 | 6 | 3 |

| PT9502 | 8ml | 21 | 25 | 6 | 8 | 3 | |

| PT9503 | 10ml | 23 | 27 | 7 | 9 | 3 | |

| PT9504 | 10ml | 24 | 29 | 8 | 13 | 3 | |

| PT9505 | 12ml | 25 | 30 | 10 | 13 | 3 | |

| PT9506 | 15ml | 27 | 30 | 11 | 14 | 3 | |

| PT9507 | 15ml | 27 | 32 | 13 | 19 | 3 | |

| PT9508 | 20ml | 28 | 33 | 15 | 18 | 4 | |

| PT9509 | 20ml | 31 | 37 | 18 | 26 | 4 | |

| PT9510 | 25ml | 30 | 36 | 19 | 23 | 4 | |

| PT9511 | 25ml | 34 | 41 | 25 | 35 | 4 | |

| PT9512 | 30ml | 32 | 40 | 22 | 27 | 6 | |

| PT9513 | 30ml | 34 | 38 | 25 | 31 | 6 | |

| PT9514 | 35ml | 33 | 42 | 25 | 32 | 6 | |

| PT9515 | 35ml | 36 | 44 | 26 | 38 | 6 | |

| PT9516 | 40ml | 34 | 43 | 30 | 36 | 7 | |

| PT9517 | 40ml | 40 | 45 | 30 | 41 | 7 | |

| PT9518 | 50ml | 42 | 50 | 36 | 51 | 8 | |

| PT9519 | 50ml | 41 | 50 | 39 | 58 | 8 | |

| PT9520 | 60ml | 39 | 48 | 46 | 54 | 9 | |

| PT9521 | 70ml | 41 | 52 | 50 | 63 | 12 | |

| PT9522 | 70ml | 45 | 55 | 53 | 75 | 12 | |

| PT9523 | 80ml | 47 | 52 | 51 | 72 | 14 | |

| PT9524 | 90ml | 48 | 57 | 52 | 81 | 15 | |

| PT9525 | 100ml | 48 | 62 | 70 | 91 | 17 | |

| PT9526 | 120ml | 57 | 57 | 84 | 98 | 22 | |

| PT9527 | 125ml | 59 | 59 | 97 | 114 | 25 |

Material: Platinum Pt, Platinum Gold Pt/Au, Platinun Rhodium Pt/Rh, Platinum Iridium Pt/Ir

Composition: Pt, PtAu5, PtIr5, PtRh5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%, Ir ≥ 99.99%, Rh ≥ 99.99%

Capacity: 5mL~50mL, or Customized

Other: Can be Customized

| DRAWING | Code | Capacity (ml) | B (mm) | A1 (mm) | Weight (g) | Lid Weight (g) |

| PT9401 | 10 | 28 | 25 | 7 | 6 |

| PT9402 | 15 | 31 | 31 | 11 | 8 | |

| PT9403 | 20 | 35 | 33 | 15 | 9 | |

| PT9404 | 25 | 35 | 36 | 19 | 10 | |

| PT9405 | 30 | 36 | 40 | 22 | 11 | |

| PT9406 | 40 | 42 | 42 | 30 | 13 | |

| PT9407 | 50 | 44 | 45 | 38 | 14 |

Material: Platinum Pt, Platinum Gold Pt/Au, Platinun Rhodium Pt/Rh, Platinum Iridium Pt/Ir

Composition: Pt, PtAu5, PtIr5, PtRh5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%, Ir ≥ 99.99%, Rh ≥ 99.99%

Capacity: 20mL~500mL, or Customized

Other: Can be Customized

| Platinum Dish | Capacity (mL) | A1 (mm) | B (mm) | Weight (g) |

| 20 | 50 | 18 | 16 |

| 25 | 50 | 18.5 | 17 | |

| 30 | 50 | 19 | 18 | |

| 35 | 50 | 20 | 19 | |

| 40 | 50 | 34 | 20 | |

| 50 | 60 | 28 | 40 | |

| 60 | 60 | 30 | 45 | |

| 75-80 | 65 | 30-35 | 45-50 | |

| 90 | 70 | 35 | 50 | |

| 100 | 75 | 36 | 60 | |

| 150 | 80 | 38 | 70 | |

| 200 | 90 | 45 | 90 | |

| 250 | 92 | 56 | 110 | |

| Silver Beaker | A1 (mm) | B (mm) | Weight (g) | |

| 250ml | 66 | 82 | 200-250 |

Material: Platinum Gold

Composition: PtAu5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%

Capacity: 20mL~250mL, or Customized

| Platinum Dish | Capacity (mL) | A1 (mm) | B (mm) | Weight (g) |

| 20 | 50 | 18 | 16 |

| 25 | 50 | 18.5 | 17 | |

| 30 | 50 | 19 | 18 | |

| 35 | 50 | 20 | 19 | |

| 40 | 50 | 34 | 20 | |

| 50 | 60 | 28 | 40 | |

| 60 | 60 | 30 | 45 | |

| 75-80 | 65 | 30-35 | 45-50 | |

| 90 | 70 | 35 | 50 | |

| 100 | 75 | 36 | 60 | |

| 150 | 80 | 38 | 70 | |

| 200 | 90 | 45 | 90 | |

| 250 | 92 | 56 | 110 | |

| Silver Beaker | A1 (mm) | B (mm) | Weight (g) | |

| 250ml | 66 | 82 | 200-250 |

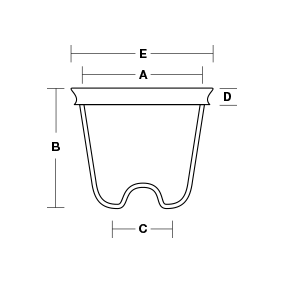

Material: Platinum Gold

Composition: PtAu5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%

Model: Dimple Crucibles, Flat Base Crucibles, Molds

Capacity: Customized

| Dimple Type | Code | A | B | C | D | E | Weight (g) |

| CC1 | 37 | 32 | 20 | 5 | 43 | 26 |

| CC2 | 37 | 32 | 20 | 5 | 43 | 30 | |

| CC8 | 35 | 35 | 21 | 5 | 43 | 60 | |

| CC21 | 36.5 | 32 | 20 | 5.5 | 43 | 26 | |

| CC22 | 36.5 | 32 | 20 | 5.5 | 43 | 31 |

| Flat Base Type | Code | A | B | C | D | E | Weight (g) |

| CC3 | 35 | 35 | 17 | 3.5 | 40 | 21 |

| CC4 | 35 | 35 | 21 | 3.5 | 44 | 26 | |

| CC5-N | 37 | 32 | 26 | 5 | 43 | 30 | |

| CC23 | 31.6 | 35 | 15 | 3.9 | 43 | 24 | |

| CC24 | 36.5 | 32 | 20 | 5.5 | 43 | 26 | |

| CC25 | 36.5 | 32 | 20 | 5.5 | 43 | 30 |

| Flat Base SD Type | Code | A | B | C | D | E | Weight (g) |

| CC5 | 37 | 32 | 26 | 5 | 43 | 30 |

| CC26 | 36.5 | 32 | 20 | 5.5 | 43 | 26 | |

| CC27 | 36.5 | 32 | 20 | 5.5 | 43 | 30 |

| Mold Type | Code | A | B | C | Weight (g) |

| CM1 | 30/31 | 6 | 39 | 18 / 30 |

| CM2 | 31/33 | 6 | 41 | 19 / 32 | |

| CM3 | 32/34 | 6 | 41 | 21 / 36 | |

| CM4 | 32/38 | 6 | 45 | 22 / 36 | |

| CM5 | 35/37 | 6 | 44 | 25 / 48 | |

| CM6 | 38/41 | 6 | 49 | 29 / 48 | |

| CM7 | 40/42 | 6 | 49 | 34 / 48 | |

| CM8 | 37/40 | 6 | 49 | 28 / 48 | |

| CM9 | 30/32 | 6 | 39 | 21 / 21 | |

| CM10 | 38/40 | 6 | 48 | 34 / 43 | |

| CM13 | 32/36 | 6 | 45 | 40 / 50 | |

| CM21 | 31.5/32.6 | 6 | 41 | 31 | |

| CM22 | 34.5/35.6 | 3.5 | 44 | 44 | |

| CM23 | 39.5/40.6 | 3.5 | 49 | 49 |

Material: Platinum Gold

Composition: PtAu5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%

Model: Crucibles, Molds

Capacity: Customized

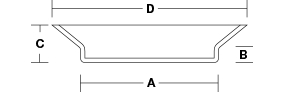

| Crucible | Code | A (mm) | B (mm) | C (mm) | D (mm) | Weight (g) |

| PC1 | 41 | 40 | 41 | 49 | 116 |

| PC2 | 41 | 40 | 41 | 49 | 80 | |

| PC3 | 44 | 40 | 44 | 52 | 90 | |

| PC4 | 38 | 40 | 42 | 50 | 75 | |

| PC5 | 28 | 40 | 38 | 50 | 70 | |

| PC6 | 28 | 40 | 40 | 50 | 75 | |

| PC7 | 22 | 46 | 34 | 54 | 80 | |

| PC9 | 41 | 40 | 42 | 50 | 90 | |

| PC10 | 32.7 | 40 | 40.4 | 50 | 78 |

| Mold | Code | A (mm) | B (mm) | C (mm) | D (mm) | Weight (g) |

| PM2 | 30/32 | 3 | 5 | 55 | 40 |

| PM3 | 30/32 | 3.5 | 11.5 | 65 | 50 | |

| PM4 | 39.5/40.5 | 3.5 | 11.5 | 65 | 58 | |

| PM5 | 35.5/36.5 | 3.5 | 11.5 | 65 | 50 | |

| PM6 | 35.5/36.5 | 3 | 5 | 55 | 50 | |

| PM7 | 39.5/40.5 | 3 | 11.5 | 65 | 58 | |

| PM8 | 32/33.5 | 3.5 | 11.5 | 65 | 50 | |

| PM9 | 39.5/40.5 | 3 | 11.5 | 65 | 58 | |

| PM10 | 33.5/35.5 | 3.5 | 11.5 | 65 | 50 | |

| PM11 | 30/32 | 3.6 | 10.2 | 65 | 70 |

Material: Platinum Gold

Composition: PtAu5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%

Model: Three-Pin Crucible, Rolled Lip Crucible, Square Molds

Capacity: Customized

| Three-Pin | Code | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | Weight (g) |

| SC1 | 35 | 38 | 20 | 5 | 60 | 31 |

| SC2 | 44 | 38 | 26 | 5 | 60 | 50 | |

| SC3 | 39 | 43 | 22 | 5 | 60 | 38 |

| Rolled Lip | Code | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | Weight (g) |

| SC4 | 33 | 38 | 21 | 7 | 39 | 40 |

| Square Flange Mold | Code | A (mm) | B (mm) | C (mm) | Weight (g) |

| SM1 | 29/31 | 3 | 41 | 27 |

| SM2 | 30/32 | 3 | 41 | 29 | |

| SM3 | 32/34 | 3 | 41 | 31 | |

| SM4 | 34/36 | 3 | 51 | 45 | |

| SM5 | 39/41 | 3 | 51 | 45 |

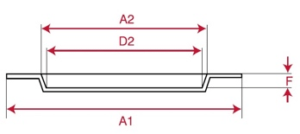

Material: Platinum Gold

Composition: PtAu5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%

Model: Flared Crucible, Rolled Lip Crucible, Mold

Capacity: Customized

| Crucibles | Code | Description | B (mm) | A1 (mm) | D (mm) | Weight (g) |

| PT0701 | Flared Type | 36 | 36 | 20 | 40 |

| PT0702 | Flared Type | 43 | 36 | 20 | 40 | |

| PT0703 | Flared Type | 36.5 | 34 | 20 | 40 | |

| PT0704 | Rolled lip type | 38 | 33 | 21 | 40 | |

| PT0705 | Rolled lip type | 30 | 33 | 20 | 30 | |

| PT0706 | Rolled lip type | 35 | 40 | 22 | 36 |

| Mold | Code | D2 (mm) | A2 (mm) | A1 (mm) | F (mm) | Weight (g) |

| PT0707 | 30 | 32 | 42 | 3 | 60-100 |

| PT0708 | 30 | 32 | 42 | 4 | 60-100 | |

| PT0709 | 30 | 32 | 46 | 3 | 60-100 | |

| PT0710 | 32 | 34 | 46 | 3 | 60-100 | |

| PT0711 | 33 | 35 | 46 | 3 | 60-100 | |

| PT0712 | 39 | 41 | 52 | 3 | 60-100 | |

| PT0713 | 39 | 41 | 56 | 3 | 60-100 |

Material: Platinum Gold

Composition: PtAu5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%

Model: Crucible, Mold

Capacity: Customized

| Crucible | Code | A (mm) | B (mm) | C (mm) | Weight (g) |

| KC1 | 40 | 32 | 28 | 26 |

| KC2 | 40 | 32 | 28 | 30 | |

| KC4-flared | 44 | 32 | 28 | 43 | |

| KC7 | 40 | 32 | 32 | 28 | |

| KC8 | 40 | 32 | 32 | 33 |

| Mold | Code | A (mm) | B (mm) | C (mm) | Weight (g) |

| KM1 | 30/32 | 6 | 39 | 18 or 30 |

| KM2 | 31/33 | 6 | 41 | 19 or 32 | |

| KM3 | 32/34 | 6 | 41 | 21 or 36 | |

| KM4 | 32/38 | 6 | 45 | 22 or 36 | |

| KM5 | 35/37 | 6 | 44 | 25 or 40 | |

| KM8 | 37/40 | 6 | 49 | 28 or 48 | |

| KM6 | 38/41 | 6 | 49 | 29 or 48 | |

| KM7 | 40/42 | 6 | 49 | 34 or 48 | |

| KM9 | 30/32 | 6 | 39 | 18 or 30 |

Material: Platinum Gold

Composition: PtAu5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%

Model: Crucible, Mold

Capacity: Customized

Crucible | Code | B (mm) | A2 (mm) | D (mm) | A1 (mm) | Weight (g) |

| PT9801 | 35 | 37 | 20 | 44 | 45 |

PT9802 | 38 | 35 | 21 | 44 | 45 |

Mold | Code | D2 (mm) | A2 (mm) | A1 (mm) | B (mm) | C (mm) | Weight (g) |

| PT9803 | 35 | 36 | 44 | 7.2 | 0.8 | 35 |

PT9804 | 35 | 38.5 | 44 | 7.2 | 0.8 | 45 | |

PT9805 | 39 | 41 | 47 | 4.2 | 0.8 | 40 | |

PT9806 | 39 | 41 | 52 | 5 | 0.8 | 40 |

Material: Platinum Gold

Composition: PtAu5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%

Model: Crucible, Mold

Capacity: Customized

| Crucible | Code | A1 (mm) | B (mm) | D (mm) | Weight (g) |

| PT9701 | 41 | 49.5 | 20 | 38 |

| PT9702 | 35 | 48 | 20 | 35 |

| Mold | Code | D2 (mm) | A2 (mm) | A1 (mm) | B (mm) | Weight (g) |

| PT9703 | 31 | 33 | 41 | 3 | 30 |

| PT9704 | 39 | 41 | 51 | 3 | 45 |

Material: Platinum Gold

Composition: PtAu5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%

Model: Crucible, Mold

Capacity: Customized

| Crucible | Code | Description | A1 (mm) | D (mm) | B (mm) | Weight (g) |

| PT9901 | No rim (illustrated) | 50 | 38.5 | 30 | 76 |

| PT9902 | No rim | 50 | 38.5 | 30 | 90 | |

| PT9903 | No rim | 50 | 38.5 | 30 | 115 | |

| PT9904 | With upper rim | 50 | 38.5 | 30 | 110 | |

| PT9905 | Upper rim and curved base | 50 | 38.5 | 30 | 115 | |

| PT9906 | With crucible support | 36 | 22 | 38.5 | 40 |

| Mold | Code | Shape | D2 (mm) | A2 (mm) | A1 (mm) | B (mm) | C (mm) | Weight (g) |

| PT9907 | Round | 29 | 31 | 44 | 3 | 1.5 | 40 |

| PT9908 | Square | 29 | 31 | 44 | 3.5 | 2.5 | 65 | |

| PT9909 | Round | 39 | 41 | 52 | 4 | 1.5 | 50 | |

| PT9910 | Square | 38 | 40 | 50 | 4.5 | 3 | 113 |

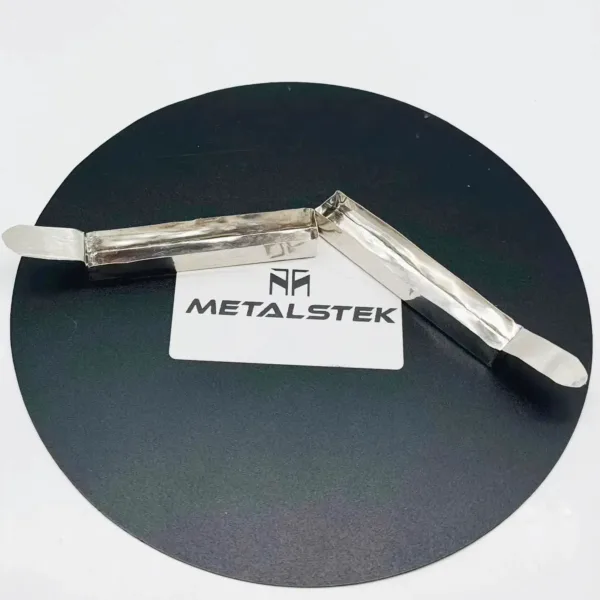

Material: Platinum or Platinum Gold

Composition: Pt, PtAu5

Purity: Pt ≥ 99.95%, Au ≥ 99.99%

Capacity: 1mL~10mL, or Customized

| Product | Capacity | Top Length | Bottom Width | Height | Base Thickness |

| Platinum Combustion Boat | ≈ 0.10mL | 10mm | 4mm | 3mm | 0.15mm |

| ≈ 0.15mL | 15mm | 6mm | 4mm | 0.15mm | |

| ≈ 0.20mL | 12mm x 6mm | 11mm x 4mm | 4mm | 0.15mm | |

| ≈ 0.45mL | 25mm | 5mm | 4mm | 0.15mm | |

| ≈ 0.50mL | 20mm | 7mm | 4mm | 0.15mm | |

| ≈ 0.50mL | 30mm | 5mm | 4mm | 0.15mm | |

| ≈ 2.15mL | 40mm | 12mm | 5mm | 0.15mm | |

| ≈ 3.75mL | 35mm | 12mm | 10mm | 0.15mm | |

| ≈ 4.5mL | 70mm | 9mm | 8mm | 0.20mm | |

| ≈ 5.40mL | 50mm | 12mm | 10mm | 0.15mm | |

| ≈ 6.0mL | 80mm | 10mm | 8mm | 0.20mm | |

| ≈ 6.50mL | 60mm | 12mm | 10mm | 0.15mm | |

| ≈ 11mL | 100mm | 12mm | 10mm | 0.20mm | |

| ≈ 15mL | 120mm | 14mm | 10mm | 0.20mm | |

| ≈ 17.5mL | 140mm | 12mm | 12mm | 0.20mm | |

| ≈ 24mL | 160mm | 12mm | 14mm | 0.20mm | |

| ≈ 36mL | 180mm | 14mm | 16mm | 0.20mm | |

| ≈ 52.5mL | 200mm | 16mm | 18mm | 0.20mm | |

| Pt Boat With Handle | 3mL | 60mm | 9mm | 9mm | |

| 4mL | 48mm | 13mm | 10mm | ||

| 6mL | 60mm | 13mm | 10mm | ||

| 9mL | 85mm | 13mm | 10mm | ||

| 12mL | 110mm | 13mm | 10mm | ||

| Pt Boat Without Handle | 3mL | 60mm | 9mm | 9mm | |

| 12mL | 100mm | 16mm | 13mm |

Material: Stainless Steel, Platinum, or Other Metals

Composition: Can be Customized

Working Temperature: Up to 2100 Degree Celsius

Size: Tailored Sizes

Applications: Matching with various crucibles, different material for different temperatures

Platinum Crucibles Molds and Boats are indispensable in scientific and industrial applications due to their exceptional thermal stability, chemical inertness, and durability. Made from pure platinum or platinum alloyed with metals like gold, iridium, and rhodium, they withstand extreme temperatures above 1,700 °C without melting or reacting with the sample, ensuring purity and accuracy in analyses. Their resilience against corrosion and ability to be reused make them a cost-effective solution for high-temperature processes, including gravimetric analysis, fusion reactions, and materials science research. Available in various sizes and designs, including those with reinforced rims or lids to prevent contamination, Platinum Crucibles Molds and Boats are tailored for different specific needs, underscoring their critical role in ensuring the reliability and precision of experimental and manufacturing processes.

MetalsTek can custom-make platinum and platinum alloy crucibles for various applications, such as semiconductors, nanoglasses, sapphire growth, crystal growth, and more.

From design to mold making to production, MetalsTek is your one-stop Platinum Crucible source!

Our Platinum Crucibles, including its alloys of PtAu, PtRh and PtIr Molds and Boats are clearly labeled externally to ensure efficient identification and quality control. To prevent any damage during storage or transportation, we take great care.

Platinum Crucibles have become the gold standard in various industries due to their exceptional versatility and reliability. From laboratories to manufacturing plants, these crucibles offer unparalleled performance in high-temperature applications.

In this comprehensive guide, we will delve into the fascinating world of platinum crucibles, exploring their unique properties, applications, and benefits.

Platinum’s remarkable resistance to corrosion, thermal conductivity, and high melting point make it an ideal material for crucibles. Whether it’s for precise chemical analysis, fusion experiments, or melting and casting processes, platinum crucibles deliver consistent and accurate results.

With a brand voice that reflects expertise and authority, we will walk you through the different types of platinum crucibles available, their specific uses, and the factors to consider when choosing the right one for your needs.

Join us on this journey as we unveil the remarkable versatility and reliability of platinum crucibles, and discover why they are the go-to choice for professionals across industries. Welcome to the world of platinum crucibles – where precision meets durability.

Platinum crucibles are renowned for their exceptional properties that make them indispensable in various applications. One of the primary advantages is their unparalleled resistance to corrosion. Unlike other materials that can degrade when exposed to harsh chemicals or high temperatures, platinum maintains its integrity, allowing for precise and accurate results. This resistance ensures that the crucibles can withstand intense conditions without contaminating the materials inside, which is critical for scientific experiments and manufacturing processes. The longevity of platinum crucibles translates to cost-effectiveness, as they require less frequent replacement compared to their counterparts made from less durable materials.

Additionally, platinum crucibles exhibit remarkable thermal conductivity. This means they can heat up quickly and evenly, resulting in uniform temperature distribution throughout the crucible. Such efficiency is particularly crucial in high-temperature applications where even slight temperature variations can lead to erroneous results or compromised material properties. The ability to withstand extreme temperatures, paired with their thermal conductivity, makes platinum crucibles a preferred choice for melting and casting processes, as well as for applications requiring precise temperature control.

Another significant advantage of platinum crucibles is their ability to retain thermal stability. They do not expand or contract significantly with temperature changes, which helps maintain the integrity of the experimental setup or manufacturing process. This stability is vital when dealing with sensitive reactions or materials that require strict adherence to temperature specifications. Furthermore, platinum is chemically inert, meaning it does not react with most substances, thereby ensuring that the purity of samples is preserved. This combination of qualities makes platinum crucibles an essential tool for professionals seeking reliability and accuracy in their work.

In addition to their high melting point, platinum crucibles are known for their excellent thermal shock resistance. This property allows them to endure sudden changes in temperature without cracking or breaking. For professionals in laboratories and industrial settings, this means that they can transition from heating to cooling quickly without worrying about damaging the crucibles. This characteristic is particularly beneficial in processes that involve rapid heating and cooling cycles, ensuring that the crucibles can be reused without loss of performance.

Moreover, the physical structure of platinum crucibles is designed for optimal utility. They are available in various shapes and sizes, catering to different needs, whether for small-scale experiments or large-scale industrial applications. The smooth interior surface of platinum crucibles minimizes the risk of material adherence, facilitating easy cleaning and transfer of samples. This combination of high-performance characteristics makes platinum crucibles a versatile choice for professionals in scientific research and manufacturing.

The pricing of platinum crucibles varies significantly based on several key factors, making it essential for consumers and industries to understand the market dynamics. Primarily, the demand for platinum labware influences its prices. As industries evolve, with increasing applications in fields such as metallurgy, electronics, and materials science, the need for high-quality crucibles has risen, leading to fluctuations in pricing.

Another crucial factor impacting the cost is the raw material costs associated with platinum itself. The price of platinum tends to be volatile and can be affected by global economic conditions, mining outputs, and investment trends. For instance, when the demand for platinum increases in jewelry manufacturing or investment markets, the cost of platinum gold crucibles can see a corresponding rise. Moreover, the purity of the platinum used in the crucibles, such as platinum rhodium crucibles, often dictates higher prices due to the added complexities in sourcing these materials.

Manufacturing complexity also plays a vital role in determining platinum crucible prices. Different types of crucibles, such as the platinum boat or specialized designs for specific applications, may require advanced techniques and skilled craftsmanship to produce. Customizations, such as size variations or unique shapes tailored for particular industrial processes, can further influence costs.

A comparative analysis of prices reveals that standard platinum crucibles generally have a base price that can escalate with added features or higher purity levels. Companies like Metalstek are recognized as trusted suppliers within this market, offering competitive pricing on various forms of platinum labware. Consequently, industries should perform thorough market research and price comparisons to ensure they acquire the most cost-effective solutions for their specific applications, thus understanding the multifaceted nature of platinum crucible pricing.

The applications of platinum crucibles span across multiple industries, showcasing their versatility and reliability. In the field of chemistry and pharmaceuticals, platinum crucibles are essential for conducting high-temperature reactions and analyses. They are often used in processes such as gravimetric analysis, where precise measurements of mass are crucial. The inert nature of platinum ensures that the results obtained are not influenced by the crucible material, making it an ideal choice for obtaining accurate data in chemical experiments.

In metallurgy, platinum crucibles play a vital role in the melting and casting of precious metals and alloys. Their ability to withstand extreme temperatures without degradation allows for the effective transformation of raw materials into usable forms. Gold and silversmiths, for example, rely on platinum crucibles for their processes, as the crucibles can handle the high heat required to melt these metals without contaminating them. This application highlights the importance of platinum crucibles in producing high-quality materials in the jewelry and electronics industries.

Moreover, in the realm of environmental testing, platinum crucibles are utilized for analyzing soil and water samples. Their resistance to corrosion and chemical reactions makes them suitable for handling samples that may contain aggressive substances. The use of platinum crucibles ensures that the testing processes yield reliable and consistent results, which is essential for environmental monitoring and compliance. As industries continue to evolve, the demand for platinum crucibles remains strong due to their unique properties and wide-ranging applications.

Various platinum crucibles are available, each designed for specific applications and requirements. One common type is the standard platinum crucible, typically used for general laboratory purposes. These crucibles come in different sizes and shapes, such as conical, cylindrical, or flat-bottomed, allowing users to choose based on their specific experimental needs. Standard platinum crucibles are often utilized in chemical analysis, melting processes, and high-temperature reactions.

Another type is the platinum-coated crucible, which features a base material coated with a thin layer of platinum. This design provides a cost-effective alternative to solid platinum crucibles while still delivering many of the benefits associated with platinum. Platinum-coated crucibles are particularly suitable for applications where high purity is less critical, enabling laboratories to manage their budgets effectively without sacrificing too much quality.

Out of the shapes, Platinum Crucibles can also be categorized by materials. Platinum alloyed with other expensive metals is widely used, too. The typical alloys include Platinum Gold (Pt/Au), Platinum Rhodium (Pt/Rh), Platinum Iridium (Pt/Ir), and more.

For specialized applications, there are also custom-designed platinum crucibles. These are tailored to meet the specific requirements of particular industries or experiments. Custom crucibles can be designed in various shapes, sizes, and thicknesses to optimize performance for unique processes, ensuring users can access the right tools for their needs. The variety of platinum crucibles available allows professionals to select the most appropriate option for their applications, ensuring efficiency and accuracy in their work.

Choosing the right platinum crucible involves considering several factors to ensure optimal performance for your specific applications. First and foremost, it’s essential to assess the intended use of the crucible. Different applications may require different shapes and sizes to achieve the best results. For instance, if you are conducting a fusion experiment, a larger crucible may be necessary to accommodate the volume of material being melted. Conversely, for precise chemical analyses, smaller crucibles may be more appropriate.

Another critical factor to consider is the temperature range that the crucible will be subjected to. Different platinum crucibles have varying capacities for heat resistance, so it is vital to select one that can withstand the specific temperatures involved in your processes. Additionally, consider whether you require a standard crucible or a custom-designed option, especially if your application has unique requirements. Custom crucibles can offer additional benefits in terms of efficiency and performance.

Finally, always evaluate the quality and source of the platinum crucibles. Purchasing from reputable suppliers ensures that you receive high-quality materials that meet industry standards. Look for certifications or endorsements from recognized organizations to confirm the crucible’s reliability. Investing in high-quality crucibles from trusted manufacturers will ultimately enhance the accuracy and longevity of your experiments or production processes, making your selection process even more critical.

Proper care and maintenance of platinum crucibles are essential to ensure their longevity and optimal performance. One of the first tasks in maintaining these crucibles is to implement a suitable cleaning routine. After each use, it is important to clean the crucible thoroughly to remove any residues that may have accumulated during the process. Using gentle cleaning agents or a dilute acid solution can help dissolve any contaminants without damaging the platinum surface. Avoid using abrasive materials, as they can scratch the surface and compromise the crucible’s integrity.

Storing platinum crucibles properly is equally important. They should be kept in a clean, dry environment to prevent contamination and avoid exposure to harsh chemicals that could lead to corrosion. It is advisable to store the crucibles in a protective case or container to prevent physical damage. Furthermore, if multiple crucibles are being used, ensure they are organized in a manner that minimizes the risk of mixing them up or damaging one another.

Regular inspection of the crucibles is also crucial for maintaining their functionality. Inspect for any signs of wear, such as cracks or deformations, which can occur over time, especially when subjected to extreme temperatures. If any damage is detected, it may be necessary to replace the crucible to ensure accurate results in experiments or manufacturing processes. By following these care and maintenance guidelines, users can extend the lifespan of their platinum crucibles and maintain their reliability for years to come.

Despite their widespread use, there are several misconceptions regarding platinum crucibles that can lead to misunderstandings about their capabilities and applications. One common myth is that platinum crucibles are too expensive for everyday laboratory use. While it is true that they represent a higher initial investment compared to other materials, their durability and longevity make them a cost-effective option in the long run. The reduced need for frequent replacements and the accuracy of results obtained ultimately justify the expense, especially in high-stakes applications where precision is paramount.

Another misconception is that platinum crucibles are limited to high-temperature applications alone. While they excel in high-temperature environments, their versatility extends to various chemical analyses, including those conducted at lower temperatures. Platinum’s inert nature means it can be used effectively in reactions involving reactive substances and in applications where contamination must be avoided. This versatility enables scientists and manufacturers to utilize platinum crucibles across a wide range of processes, not just those involving extreme heat.

Additionally, some may believe that platinum crucibles require extensive upkeep or specialized handling due to their perceived fragility. In reality, with proper care and maintenance, platinum crucibles are quite resilient. They are designed to withstand high temperatures and thermal shock, making them suitable for various uses without the need for overly cautious handling. Understanding the true capabilities and benefits of platinum crucibles can help professionals make informed decisions about their applications and maintenance.

When it comes to purchasing high-quality platinum crucibles, selecting the right supplier is of utmost importance. Numerous reputable manufacturers and suppliers specialize in providing premium platinum crucibles tailored for different applications. It is advisable to look for suppliers that have a proven track record in the industry and offer a range of products to meet varying needs. Established companies often provide certifications and quality guarantees, ensuring that their products adhere to industry standards.

Online marketplaces can also be a valuable resource for finding platinum crucibles. Many specialized scientific equipment suppliers and manufacturers have online platforms where customers can browse their offerings, compare prices, and read reviews. However, it is crucial to verify the credibility of the online seller and ensure that they provide detailed product specifications and customer support. Engaging with suppliers who are knowledgeable about their products can provide insights that help in making the best choice for your specific requirements.

Additionally, attending industry conferences and trade shows can be an excellent way to discover new suppliers and products. These events often showcase the latest advancements in laboratory equipment, including platinum crucibles, and provide opportunities to interact with manufacturers directly. Networking with other professionals in the field can also lead to recommendations for reliable suppliers. By exploring various purchasing avenues, professionals can secure high-quality platinum crucibles that meet their exact specifications.

In conclusion, platinum crucibles play a vital role in both scientific research and various industrial applications. Their remarkable properties, including high melting points, excellent thermal conductivity, and resistance to corrosion, make them invaluable tools in laboratories and manufacturing plants. By ensuring the purity and integrity of samples, platinum crucibles enable researchers and manufacturers to achieve accurate and reliable results, which is essential for advancing knowledge and producing high-quality materials.

The versatility of platinum crucibles allows them to be utilized across a wide range of applications, from chemical analysis to metallurgy and environmental testing. As industries continue to evolve and demand more precise and reliable tools, the importance of platinum crucibles will only grow. Their ability to withstand extreme conditions while maintaining performance is unmatched by other materials, solidifying their status as the gold standard in crucible technology.

Ultimately, understanding the advantages, properties, and applications of platinum crucibles empowers professionals to make informed decisions in their work. Whether you are conducting research or involved in manufacturing, leveraging the capabilities of platinum crucibles can significantly enhance the quality and accuracy of your processes. As we delve deeper into the complexities of science and industry, the reliability of platinum crucibles will remain a cornerstone of innovation and excellence.