Menu

MetalsTek Engineering is a leading supplier of high-quality Molybdenum Boats. We can manufacture Molybdenum Boats of various diameters, heights, and thicknesses to suit our customers’ needs.

Material: Molybdenum (Mo)

Purity: Mo≥99.95%

Density: 9.8~10.2 g/cc

Standard: ASTM B386

Size Range: Thick 0.3~30mm * Height 10~300mm * Width 10~500mm * Length 50~1,000mm

Surface: Rolling, Chemical Cleaned

Material: Molybdenum (Mo1)

Purity: Mo≥99.95%

Density: 9.8~10.2 g/cc

Shape: Quadrate Box, Round Barrel, or Customized

Size Range: Thick 0.3~30mm * Height 10~300mm * Width 10~500mm * Length 50~1,000mm

Surface: Rolling, Chemical Cleaned

Max Working Temperature: 1,400 Degree Celsius

| Fe | Ni | C | Al | O | N |

| 0.004 | 0.002 | 0.0028 | 0.0005 | 0.005 | 0.002 |

| Si | Ca | Mg | Cd | Sb | Sn |

| 0.0013 | < 0.001 | < 0.0005 | < 0.001 | < 0.0005 | < 0.0005 |

| P | Cu | Pb | Bi | Mo | |

| < 0.001 | < 0.0005 | < 0.0005 | < 0.0005 | >99.95% |

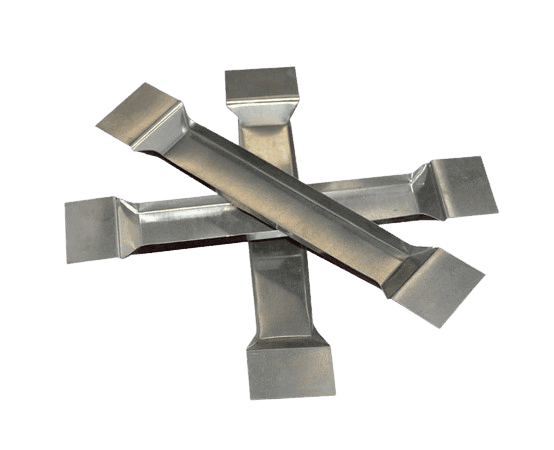

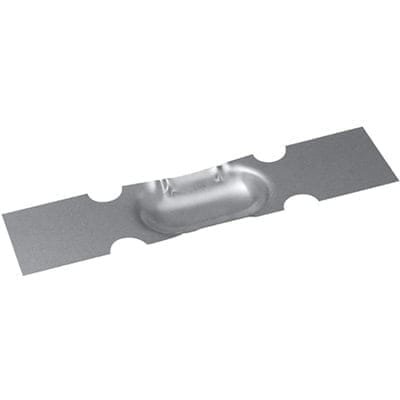

Molybdenum riveted boats are crafted from processed molybdenum plates that have been cut, folded, riveted, and welded. To meet customer needs, these molybdenum boats can be customized to various shapes, including square, rectangular, round, and trapezoidal.

Molybdenum boats and trays are excellent for evaporation materials because they can endure both low and high temperatures without degradation, unlike many other elements. This durability also makes them ideal for use in furnace machines. Additionally, molybdenum boats are widely utilized in the rare earth industry, nuclear fuel sintering, and capacitor discharge sintering.

We offer a range of molybdenum boats, trays, and wires with the shortest lead times and competitive pricing.

Closed End Tube Heaters are available in various configurations.

Durable Slab heaters are good for corrosive materials and have less deformation during heating and cooling cycles.

Molybdenum Crucibles and Molybdenum Boats are crucial in various high-temperature applications, especially in thin film deposition and evaporation processes.

Molybdenum Boats exhibit properties inherited from their source material, whether pure or molybdenum or alloy. Crafted from processed molybdenum plates subjected to cutting, folding, riveting, and welding, these boats offer versatile customization options, such as square, rectangular, round, trapezoidal, and more, catering to customer specifications.

The suitability of Molybdenum Boats for evaporation materials arises from molybdenum’s exceptional tolerance to low and high temperatures, a feature not shared by many other elements. This resilience makes them particularly effective for use as boats in furnace machines. Beyond evaporation applications, molybdenum boats find utility in diverse sectors, including the rare earth industry, nuclear fuel sintering, and capacitor-discharged sintering.

Molybdenum Crucibles and Boats are crucial in various high-temperature applications, especially thin film deposition and evaporation.

Here are some critical points about Molybdenum Crucibles and Boats for evaporation:

Molybdenum Crucibles and Boats are essential components in the deposition industry, providing a reliable and durable solution for the controlled evaporation of materials in vacuum environments. The choice of molybdenum ensures high performance and longevity in demanding applications.

Our Molybdenum Crucible & Boat are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.