Menu

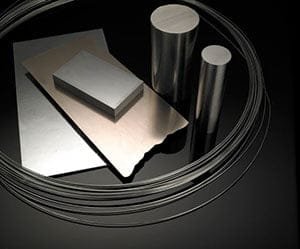

MetalsTek Engineering manufactures and supplies quality Molybdenum Rhenium products with tailored compositions, shapes and sizes.

Model: Mo/Re Wire

Compositions: 86Mo14Re, 80Mo20Re, 59Mo41Re, 55.5Mo44.5Re, 52.5Mo47.5Re, 50Mo50Re

Sizes: Diameter 0.1mm ~ 1.0mm

Color: Silver Metallic Color

Application: Thermocouple, Electronics, Furnace, Joining, Aerospace Industries, Microwave Communication

Model: Mo/Re Wire, Mo/Re Thermocouple

Compositions: 86Mo14Re, 80Mo20Re, 59Mo41Re, 55.5Mo44.5Re, 52.5Mo47.5Re, 50Mo50Re

Sizes: Diameter 0.1mm ~ 1.0mm

Color: Silver Metallic Color

Application: Thermocouple, Electronics, Furnace, Joining, Aerospace Industries, Microwave Communication

Model: Mo/Re Foil Sheet Plate

Compositions: 86Mo14Re, 80Mo20Re, 59Mo41Re, 55.5Mo44.5Re, 52.5Mo47.5Re, 50Mo50Re

Sizes: Thick 0.02mm Foil, ≥0.2mm Sheet; Width 10~600mm, Length ≤1,000mm

Color: Silver Metallic Color

Model: Mo/Re Rod

Compositions: 86Mo14Re, 80Mo20Re, 59Mo41Re, 55.5Mo44.5Re, 52.5Mo47.5Re, 50Mo50Re

Sizes: Diameter 1~17mm, or Customized

Color: Silver Metallic Color:

Application: Thermocouple, Electronics, Furnace, Joining, Aerospace Industries, Microwave Communication

Model: Mo/Re Tube Pipe

Compositions: 86Mo14Re, 80Mo20Re, 59Mo41Re, 55.5Mo44.5Re, 52.5Mo47.5Re, 50Mo50Re

Sizes: Customized

Color: Silver Metallic Color

Material: Molybdenum, Rhenium (Mo/Re)

Compositions: Mo59Re41, Mo58.5Re41.5, Mo55.5Re44.5, Mo52.5Re47.5, 50Mo50Re

Purity: 99.9%~99.999%

Color: Gray Color:

Particle Size: Customized

Shape: Spherical and Non-Spherical

Material: Molybdenum Rhenium Mo/Re

Compositions: Customized

Shape: Customized:

Size: Customized

Molybdenum-Rhenium Alloy, MoRe alloy, is a composite material that combines molybdenum and rhenium elements. It is known for its high temperature, strength, and mechanical properties, making it suitable for various applications, such as electronics, aerospace, furnace construction, and nuclear energy equipment.

The common compassion ratios are MoRe14%, MoRe41%, MoRe44.5%, MoRe47.5%, and MoRe50%. The MoRe alloy can be in different forms: powder, wire, rod, tube, foil and sheet, plate, and more.

| Shape | Specifications | Composition |

| Mo-Re Alloy Wire | φ: 0.1mm | Mo-14% Re Can be Customized MOQ: 1 KG |

| φ: 0.2mm | ||

| φ: 0.25mm | ||

| φ: 0.3mm | ||

| φ: 0.35mm | ||

φ: 0.5mm / 1.0mm | ||

| Mo-Re Alloy Rod | φ: 1-17 mm | |

| Mo-Re Alloy Thermo-couple | φ: 0.1mm | |

| φ: 0.2mm | ||

| φ: 0.25mm | ||

| φ: 0.3mm | ||

| φ: 0.35mm | ||

| φ: 0.5mm / 1.0mm | ||

| Mo-Re Alloy Foil | Width: 100mm | |

| Thickness: 0.04mm | ||

| Mo-Re Alloy Sheet | Length: 10-350mm | |

| Width: 600mm max. | ||

| Thickness: 0.2mm min. | ||

| Customized dimensions and specifications were also available. | ||

Our Molybdenum Rhenium Alloy are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

In today’s rapidly advancing technological landscape, the demand for materials that can withstand extreme conditions is higher than ever. This need has driven the development of advanced alloys with exceptional properties, such as Molybdenum Rhenium (Mo-Re). But what exactly is Molybdenum Rhenium, and why is it so crucial in modern industry?

Molybdenum rhenium alloy, often called Mo-Re, is a remarkable material that combines the strengths of two powerful elements to create a substance with exceptional properties. This alloy has garnered significant attention in various high-tech industries due to its unique characteristics and versatile applications.

Molybdenum rhenium is an alloy composed of molybdenum and rhenium, two refractory metals known for their high melting points and excellent strength at elevated temperatures. The combination of these elements results in an alloy that surpasses the individual properties of its components, making it highly desirable for specialized applications.

Molybdenum-Rhenium (Mo-Re) alloys are known for their remarkable mechanical properties and high-temperature stability, making them suitable for various demanding applications. Here are the key properties and characteristics of Mo-Re alloys:

Density:

Melting Point: Approximately 2620°C (Mo-47.5% Re alloy)

Thermal Expansion: Low coefficient of thermal expansion, beneficial for maintaining dimensional stability at high temperatures.

High Strength: Mo-Re alloys exhibit exceptional strength, even at elevated temperatures. This makes them suitable for structural components in high-temperature environments.

Ductility: Enhanced ductility compared to pure molybdenum, especially at low temperatures. The addition of rhenium significantly improves the ductility and reduces the brittleness.

Creep Resistance: Superior creep resistance at high temperatures, making these alloys ideal for applications involving prolonged exposure to high heat.

Hardness: Mo-Re alloys have high hardness, which contributes to their wear resistance and durability.

Corrosion Resistance: Good resistance to corrosion and oxidation at high temperatures, although they can be susceptible to certain aggressive environments.

Compatibility with Other Materials: Mo-Re alloys are often used in conjunction with other refractory metals due to their compatibility and similar high-temperature properties.

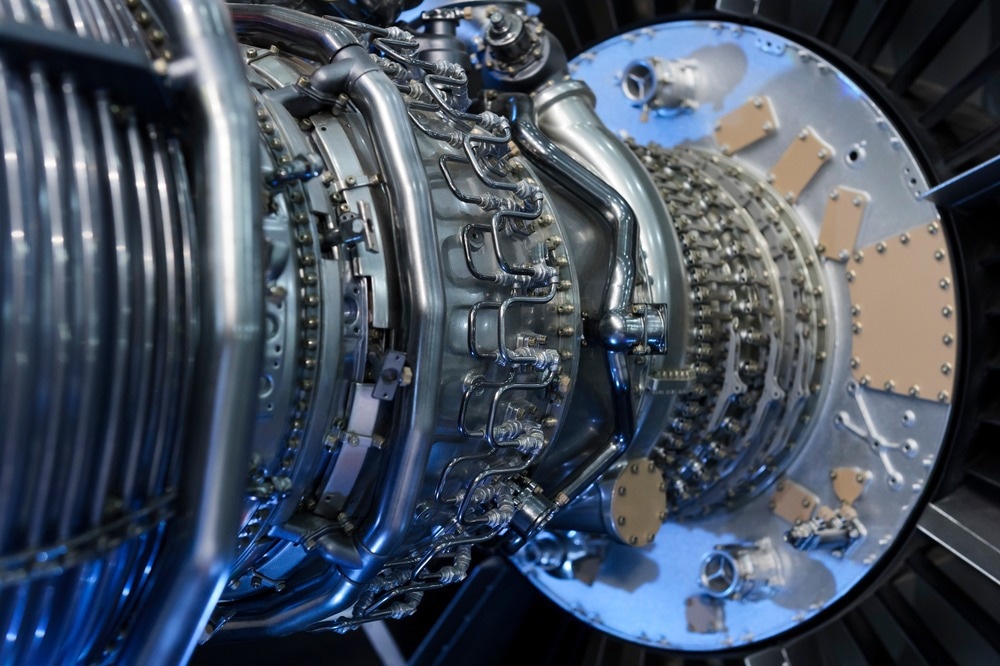

Molybdenum-Rhenium alloys are indispensable in applications that demand superior performance under extreme conditions. Their unique combination of high strength, excellent thermal stability, and resistance to wear and corrosion makes them a material of choice in aerospace, electronics, nuclear, and medical industries. By incorporating Mo-Re alloys, these industries achieve enhanced reliability, safety, and efficiency in their critical applications.

One popular form of molybdenum rhenium alloy is Mo-Re wire. This wire combines the alloy’s exceptional properties with the versatility of a wire format, making it suitable for various applications, including:

Mo-Re alloy is particularly valuable in the field of temperature measurement, where it’s used to create thermocouples. Mo-Re thermocouples are capable of measuring extremely high temperatures in harsh environments, making them indispensable in industries such as aerospace, nuclear power, and materials processing. These thermocouples offer:

While both Mo-Re wire and Mo-Re thermocouples are made from molybdenum-rhenium alloy, they have some key differences in their applications and characteristics:

Mo-Re Wire:

Mo-Re Thermocouple:

In summary, while Mo-Re wire is a versatile material used in various high-temperature applications, Mo-Re thermocouples are specialized devices engineered specifically for accurate temperature measurement in extreme environments. The thermocouple version requires more precise control of composition and is part of a complete temperature measurement system.

Choosing Molybdenum-Rhenium alloys offers many advantages, including unparalleled high-temperature performance, superior mechanical properties, and excellent thermal and electrical conductivity. Their resistance to corrosion and oxidation further enhances their appeal for use in demanding applications across aerospace, electronics, nuclear, and medical industries. Incorporating Mo-Re alloys ensures enhanced reliability, durability, and efficiency, making them a superior choice for critical high-performance applications.

While molybdenum rhenium alloy offers numerous benefits, there are some challenges to consider:

As technology continues to advance, the demand for materials that can withstand extreme conditions is likely to grow. Molybdenum rhenium alloy, with its exceptional properties, is well-positioned to play a crucial role in future innovations across various industries.Ongoing research is focused on optimizing the composition and production methods of Mo-Re alloy to enhance its properties further and potentially reduce costs. Additionally, efforts are being made to develop new applications that can benefit from the unique characteristics of this remarkable material.In conclusion, molybdenum rhenium alloy represents a significant advancement in materials science, offering a combination of properties that make it indispensable in numerous high-tech applications. From Mo-Re wire to Mo-Re thermocouples, this alloy continues to push the boundaries of what’s possible in extreme environments. As our understanding of this alloy grows and manufacturing techniques improve, we can expect to see even more innovative uses for Mo-Re in the future, driving progress in industries that operate at the cutting edge of technology.