Menu

MetalsTek Engineering is a leading supplier of Tantalum products. We offer competitive pricing and excellent lead times on all our materials, and we can supply custom materials per any specs / drawings you provide us.

Tantalum, a transition metal classified on the Periodic Table, boasts unique properties that contribute to its significance across various industries. With a distinct silvery-blue hue, tantalum exhibits remarkable attributes:

Pure Tantalum

Shapes: lump, ingot, foil, strip, sheet, plate, tube, pipe, capillary, bar, rod, wire, wire mesh, disc, mesh, crucible, flange, marker band, ribbon, powder, single crystal

Purity: Ta≥99.9%

Tantalum Alloys

Shapes: foil, strip, sheet, plate, board, tube, pipe, rod, bar, wire, disc, powder, etc.

Available in various forms.

Tantalum Compounds & Catalyst

Tantalum Oxide (Tantalum Pentoxide, Ta2O5): powder, 3N-5N

Tantalum Chloride (Tantalum Pentachloride, TaCl5): powder, >99.9%

Tantalum Carbide (TaC): powder, >99%

Tantalum Silicide (TaSi2): powder, ≥99.9%

Lithium Tantalate Wafers (LiTaO3 Wafers)

Tantalum Evaporation Materials

Ta, Ta/Al, Ta/Mo, Ta2O5, TaN, TaC, TaSi2, TaS2, TaB2, TaSe2, TaTe2, etc.

Purity: ≥99.9%

Other Tantalum Products

Lithium Tantalate Wafers, Tantalum Single Crystal, Potassium Tantalate (KTaO3) Crystal Substrates, etc.

| Phase At STP | Solid | Electrical Resistivity | 131 nΩ⋅m (at 20 °C) |

| Melting Point | 3,290 K (3,017 °C/5,463 °F) | Magnetic Ordering | Paramagnetic |

| Boiling Point | 5,731 K (5,458 °C/9,856 °F) | Young'S Modulus | 186 GPa |

| Density (Near R.T.) | 16.69 g/cm3 | Shear Modulus | 69 GPa |

| When Liquid (At M.P.) | 15 g/cm3 | Bulk Modulus | 200 GPa |

| Tensile Strength | 250(1725) KSI(Mpa)-RT | Poisson Ratio | 0.34 |

| Heat Of Vaporization | 753 kJ/mol | Mohs Hardness | 6.5 |

| Molar Heat Capacity | 25.36 J/(mol·K) | Vickers Hardness | 870–1,200 MPa |

| Thermal Expansion | 6.3 µm/(m⋅K) (at 25 °C) | Brinell Hardness | 440–3,430 MPa |

| Thermal Conductivity | 57.5 W/(m⋅K) | Cas Number | 7440-25-7 |

| Element | C | O | N | H | Fe | Mo | Nb | Ni | Si | Ti | W |

| R05200 (%,Max) | 0.01 | 0.015 | 0.01 | 0.0015 | 0.01 | 0.02 | 0.1 | 0.01 | 0.005 | 0.01 | 0.05 |

| R05400 (%,Max) | 0.01 | 0.03 | 0.01 | 0.0015 | 0.01 | 0.02 | 0.1 | 0.01 | 0.005 | 0.01 | 0.05 |

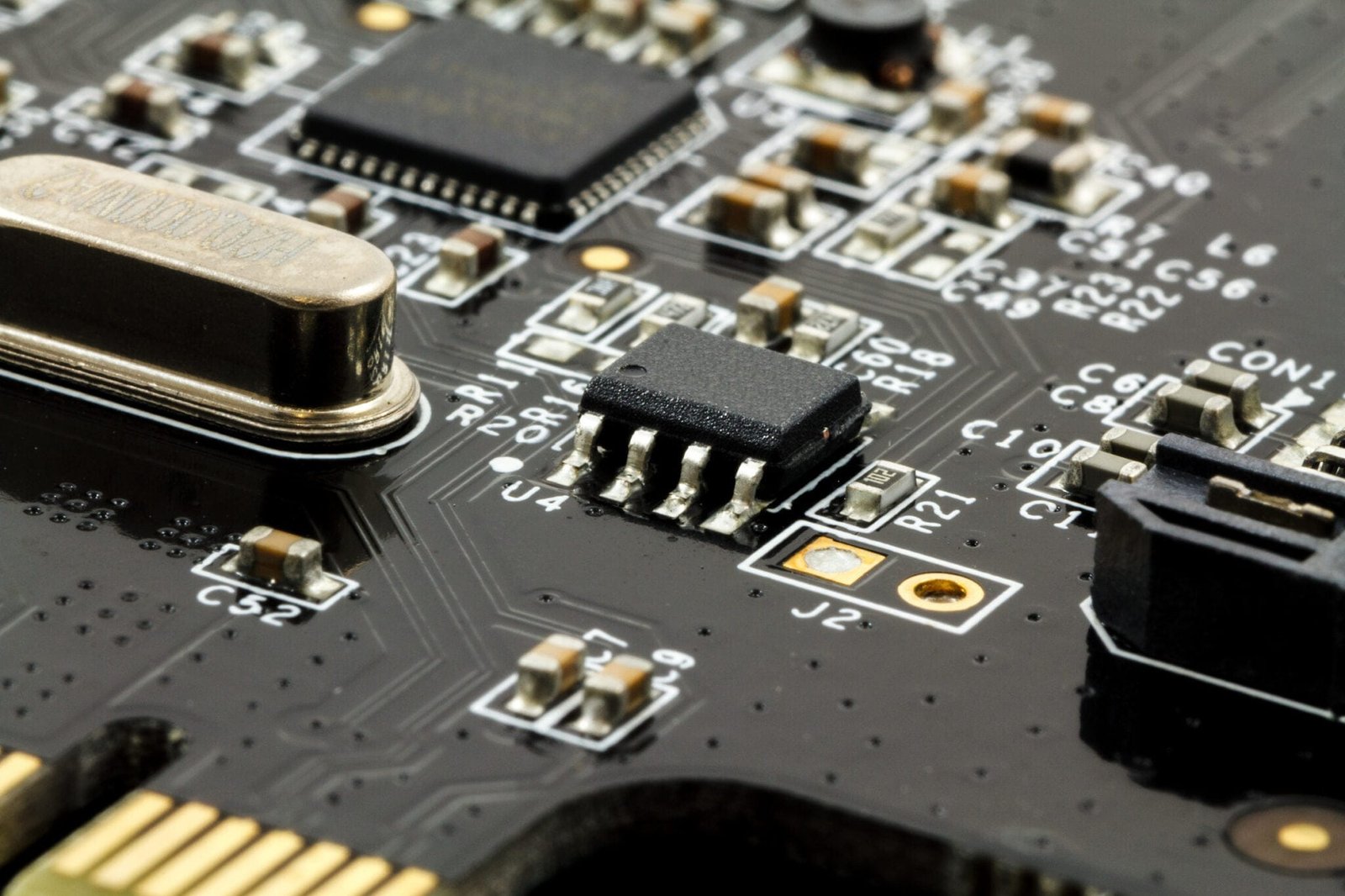

Tantalum’s unique combination of properties makes it an indispensable material across various industries, including electronics, aerospace, healthcare, and research. It contributes significantly to technological innovation and advancement.

Tantalum and niobium, often called “sister elements,” share several similarities due to their close relationship in the periodic table and comparable chemical properties. These elements exhibit nearly identical chemical behaviors and physical properties, often occurring together in nature due to their analogous atomic structures.

For more about Niobium, please click Niobium Products.