Menu

MetalsTek Engineering stands at the forefront of materials innovation, and its expertise extends to advanced compounds such as Titanium Carbide (TiC). Leveraging the unique properties of TiC, MetalsTek Engineering excels in providing cutting-edge solutions for industries demanding high-performance materials. Whether in cutting tools, wear-resistant components, or refractory materials, MetalsTek Engineering continues to drive innovation and excellence in advanced materials. Choose MetalsTek Engineering for a transformative partnership in the world of Titanium Carbide applications.

Material: Titanium Carbide, TiC

Purity: 99.5% Min, C-20.05%

Properties: Gray, 59.91 MW. 4.93 g/cc Density, 3,160ºC M.P.

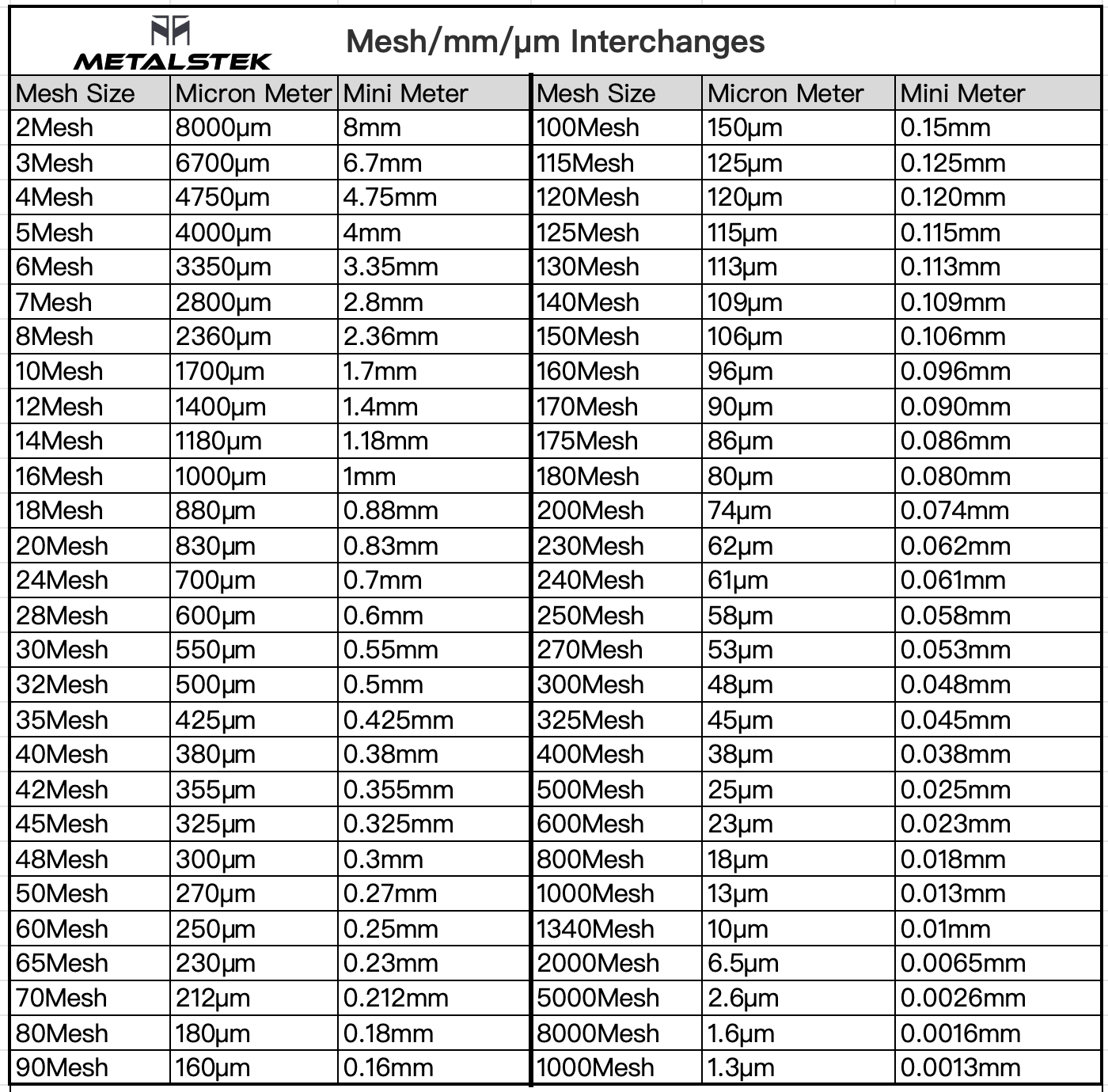

Particle Size: 5~500μm / 5~400 Mesh Size

D50: 0.8-1μm/ 3-5μm/ Customized, Plasma Spray Grade

| Grade | T.C | F.C | O | N | Al | Si | K | Na | Fsss(μm) |

|---|---|---|---|---|---|---|---|---|---|

| TiC-1 | 19.0-19.9 | ≤0.3 | ≤0.35 | ≤0.5 | ≤0.015 | ≤0.08 | ≤0.005 | ≤0.005 | 2~5 |

| TiC-2 | 19.0-19.9 | ≤0.5 | ≤1.0 | ≤0.5 | ≤0.02 | ≤0.08 | ≤0.005 | ≤0.005 | 3~6 |

Material: Titanium Carbide, TiC

Purity: 99.9% Min

Properties: Black, 59.91 MW. 3.32 g/cc Tap Density, 3,160ºC M.P.

Size: 19m2/g Surface Area, 1,000μm APS

Material: Titanium Carbide, TiC

Purity: 99.9% Min

Properties: Gray, 59.91 MW. 4.93 g/cc Density, 3,160ºC M.P.

Particle Size: 40nm APS, 65m2/g Surface Area

Solubility: Soluble in Nitric Acid and Aqua Regia

Material: Titanium Carbonitride, TiCN

Purity: 99.9%, TiC0.5N0.5

Properties: 3,000 HV Microhardness, 0.45 Friction Coefficient, 400 ºC Max Working Temp.

Hazard: Highly Flammable

| Grade | T.C | F.C | N | O | Fe | Fsss |

|---|---|---|---|---|---|---|

| TiCN40:60 | 8.0-9.5 | ≤0.3 | 12.0-13.5 | ≤0.5 | ≤0.2 | ≤5.0 |

| TiCN50:50 | 9.5-10.5 | ≤0.3 | 10.8-11.8 | ≤0.6 | ≤0.2 | ≤5.0 |

Titanium Carbonitride Applications

It Can Be Made Into Various Indexable Blades, Which Are Used in The Fields of Fine Boring, Fine Hole Processing, and “turning Instead of Grinding”;

Titanium Carbide (TiC), CAS No. 12070-08-5, is an extremely hard refractory ceramic material, like tungsten carbide, with a Mohs hardness of 9–9.5. It has a high melting point, excellent thermal and chemical stability, and is used in various applications. Titanium Carbide is used in preparing ceramics for high-speed steel machining, as an abrasion-resistant surface coating on metal parts, and as a heat shield coating for atmospheric spacecraft reentry. It is also being researched for its potential use in energy storage due to its high volumetric capacitance.

Titanium Carbide’s unique combination of properties makes it a valuable material in industries that require hard and wear-resistant components, particularly in cutting and machining applications.

Our Titanium Carbide & Carbonitride are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.