Menu

Tungsten, also known as Wolfram, its unique combination of properties, including high density(19.25g/cc), heat resistance(3,422°C/6,192 °F melting temperature), hardness, and electrical conductivity, positions it as a highly sought-after material in industries that require strength, durability, and performance in extreme conditions. Its applications span various sectors, contributing significantly to technological advancements and industrial innovation.

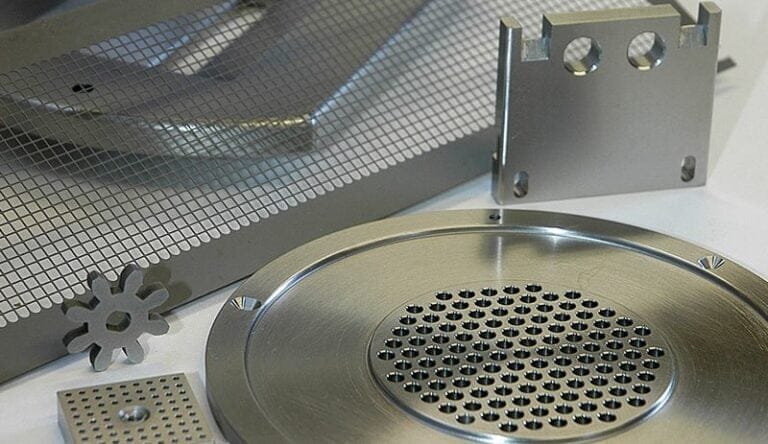

MetalsTek Engineering is a leading supplier of Tungsten products, including tungsten metals, alloys, compounds, tungsten evaporations, nanopowders, and more. We offer competitive pricing and excellent lead times on all our materials, and we can supply custom materials per any specs/drawings you provide.

Tungsten Metals

Tungsten Apron, Ball/Sphere, Bar, Blade, Boat, Canister/Pellets, Collimator, Components, Crucible, Electrode, Flange, Furnace, Heater, Penetrator, Plate, Powder, Rod/Bar, Rope, Sheet, Shield, Shielding, Sinker, Wire.

Purity of most products: ≥99.99%

Tungsten Alloys

Al-W, Fe-W, Mo-W, Ta-W, W-Ag, WC, WC/Co, WC/Co/Cr, WC/Ni, WC/Ni/Cr, WC-Co, WC-Ni, W-Cu, W-La, W-Ni, W-Re, W-Rh, etc.

Shape: Bar, Electrode, Plate, Powder, etc.

Tungsten Compounds

Purity of most products: ≥99%

Available in customized packages.

Tungsten Evaporation Materials

W, Co/W, Ni/W, Ti/W, W/Ti, V/W, Zr/W, WO3, WC, WSi2, WS2, WSe2, WTe2 Evaporation Materials.

Purity of most products: ≥99.9%

Tungsten Micro & Nano Materials

W 50nm/1000μm, WC 80nm/>30μm/1000μm, WS2 60nm/300μm, Cu/W 80nm, WO3 0.8-2.5μm/8-25μm Powder.

Tungsten Optical Products

CdWO4/PbWO4 Single Crystal Substrates, Nd:KGW, Yb:KGW

| Name | Tungsten | Z Ratio | 0.163 | |

| Symbol | W | E-Beam | Good | |

| Appearance | Grayish White, Lustrous, Metallic | E-Beam Crucible Liner Material | Direct in Hearth FABMATE® | |

| Theoretical Density | 19.25 g/cc | Temp. (°C) for Given Vap. Press. (Torr) | 10-8: 2,117 | |

| Atomic Weight | 183.84 | 10-6: 2,407 | ||

| Melting Point | 3,422°C/6,192°F | 10-4: 2,757 | ||

| Thermal Conductivity | 174 W/m.K | Comments | Forms volatile oxides. Films hard and adherent. | |

| Coefficient of Thermal Expansion | 4.5 x 10-6/K | Tensile Strength | 250(1725) KSI(Mpa)-RT |

| W (>%) | Chemical Content (<%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 99.999 | Fe | Ca | Be | Sn | Al | Ni | Zn | Sb | Pt | K | Ta | Na |

| 0.0001 | 0.00005 | 0.000005 | 0.000005 | 0.00005 | 0.00001 | 0.00005 | 0.00005 | 0.00003 | 0.000005 | 0.0001 | 0.00005 | |

| Cr | Pb | As | Mg | Ti | Bi | Mo | Cd | Cu | Ba | Co | Mn | |

| 0.000005 | 0.00001 | 0.00005 | 0.00005 | 0.000005 | 0.00001 | 0.00001 | 0.000005 | 0.000007 | 0.00001 | 0.000005 | 0.000005 | |

| 99.99 | Fe | Ca | Be | Sn | Al | Ni | Zn | Sb | Pt | K | O | Na |

| 0.0001 | 0.00045 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0005 | 0.004 | 0.0009 | |

| Cr | Pb | As | Mg | Ti | Bi | Mo | Cd | Cu | Ba | Co | Mn | |

| 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0002 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | |

| 99.95 | Fe | Ca | P | Sn | Al | Ni | N | Sb | Si | O | Pb | As |

| 0.005 | 0.003 | 0.001 | 0.0001 | 0.002 | 0.003 | 0.003 | 0.001 | 0.003 | 0.003 | 0.0001 | 0.002 | |

| Mg | C | Bi | Mo | |||||||||

| 0.002 | 0.005 | 0.0001 | 0.001 | |||||||||

Tungsten, prized for its exceptional properties, finds applications across diverse industries due to its unique combination of hardness, heat resistance, and conductivity. Some prominent applications include:

Tungsten’s versatility and robustness in extreme conditions make it vital for various industries. Its applications range from electronics and aerospace to medical equipment and industrial manufacturing, contributing significantly to technological advancements and enhancing product performance in multiple sectors.