Menu

Tungsten Powder (W Powder) is characterized by its elevated purity, fine particle size, low bulk density, uniform particles, heightened activity, expansive specific surface area, and remarkably low oxygen content post-treatment with inert gas. It is a dark gray powder with the chemical formula W. It easily disperses and finds widespread applications in various industries, notably aerospace alloys, electronic packaging alloys, electrode materials, microelectronic films, sintering aids, protective coatings, gas sensor electrodes, and more.

MetalsTek Engineering is a global supplier of high-quality Thermal Spraying Powder specializing in the provision of high-purity Tungsten Powder and Tungsten Spherical Powder.

| Classified | Grade | Particle Size | Purity | Main Impurity |

|---|---|---|---|---|

| BET/μm | ||||

| Ultra-Fine Powder | WP03 | 3.1-5.2 m²/g | W≥99.9% | O≤0.6 |

| WP04 | 2.0-3.5m²/g | W≥99.9% | O≤0.55 | |

| WP06 | 0.50-0.70μm | W≥99.9% | O≤0.4 | |

| WP07 | 0.60-0.80μm | W≥99.9% | O≤0.35 | |

| WP08 | 0.70-0.90μm | W≥99.9% | O≤0.25 | |

| Fine Powder | WP10 | 0.90-1.10μm | W≥99.9% | O≤0.2 |

| WP12 | 1.10-1.30μm | W≥99.9% | O≤0.15 | |

| WP15 | 1.30-1.70μm | W≥99.9% | O≤0.12 | |

| Medium Powder | WP20 | 1.80-2.20μm | W≥99.9% | O≤0.08 |

| WP25 | 2.30-2.70μm | W≥99.9% | O≤0.08 | |

| WP30 | 2.80-3.20μm | W≥99.9% | O≤0.06 | |

| WP35 | 3.30-3.70μm | W≥99.9% | O≤0.06 | |

| WP40 | 3.80-4.50μm | W≥99.9% | O≤0.04 | |

| WP50 | 4.50-5.50μm | W≥99.9% | O≤0.04 | |

| WP60 | 5.50-6.50μm | W≥99.9% | O≤0.04 | |

| WP70 | 6.50-7.50μm | W≥99.9% | O≤0.04 | |

| Coarse Powder | WP80 | 7.50-8.50μm | W≥99.9% | O≤0.04 |

| WP90 | 8.50-9.50μm | W≥99.9% | O≤0.04 | |

| WP100 | 9.00-11.0μm | W≥99.9% | O≤0.04 | |

| WP120 | 11.0-13.0μm | W≥99.9% | O≤0.03 | |

| Ultra-Coarse Powder | WP150 | 13.0-17.0μm | W≥99.9% | O≤0.03 |

| WP200 | 16.0-25.0μm | W≥99.9% | O≤0.03 | |

| WP300 | 25.0-35.0μm | W≥99.9% | O≤0.03 | |

| WP400 | 35.0-45.0μm | W≥99.9% | O≤0.03 |

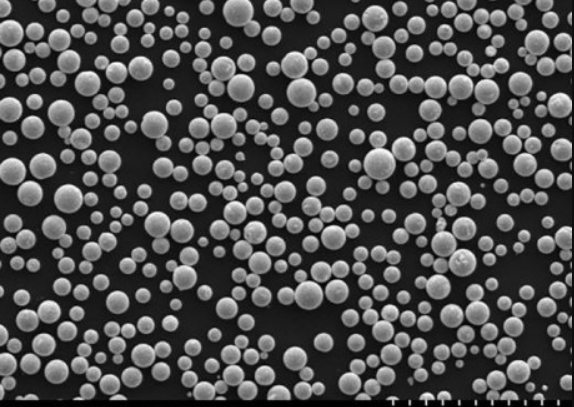

Spherical Tungsten Powder exhibits a spherical morphology, setting it apart from conventional tungsten powder. Notably, it possesses exceptional powder fluidity, a distinct advantage over regular tungsten powder. Additionally, Spherical Tungsten Powder boasts high density, a high melting point, excellent electrical conductivity, and elevated overall density, rendering it an optimal material for applications in the electrical and microelectronic fields. This specialized powder is a crucial raw material in various industries, including tungsten and tungsten alloy 3D printing, creating porous materials and high-density powder spraying.

Material: Spherical Tungsten Powder

Purity: W-99.9% Min

Density: 10.51 g/cc

Tap Density: 12.46 g/cc

Particle Size: 50nm / 100nm / 1-10μm / 5-25μm / 15-53μm

Hall Flow Rate (s/50g): 14 / 11 / 10 / 8 / 5.82

| Impurities | Al | Si | Mg | Cr | Fe | Cu | O |

| Rate (%) | <0.001 | <0.001 | <0.001 | <0.005 | <0.001 | <0.005 | <0.015 |

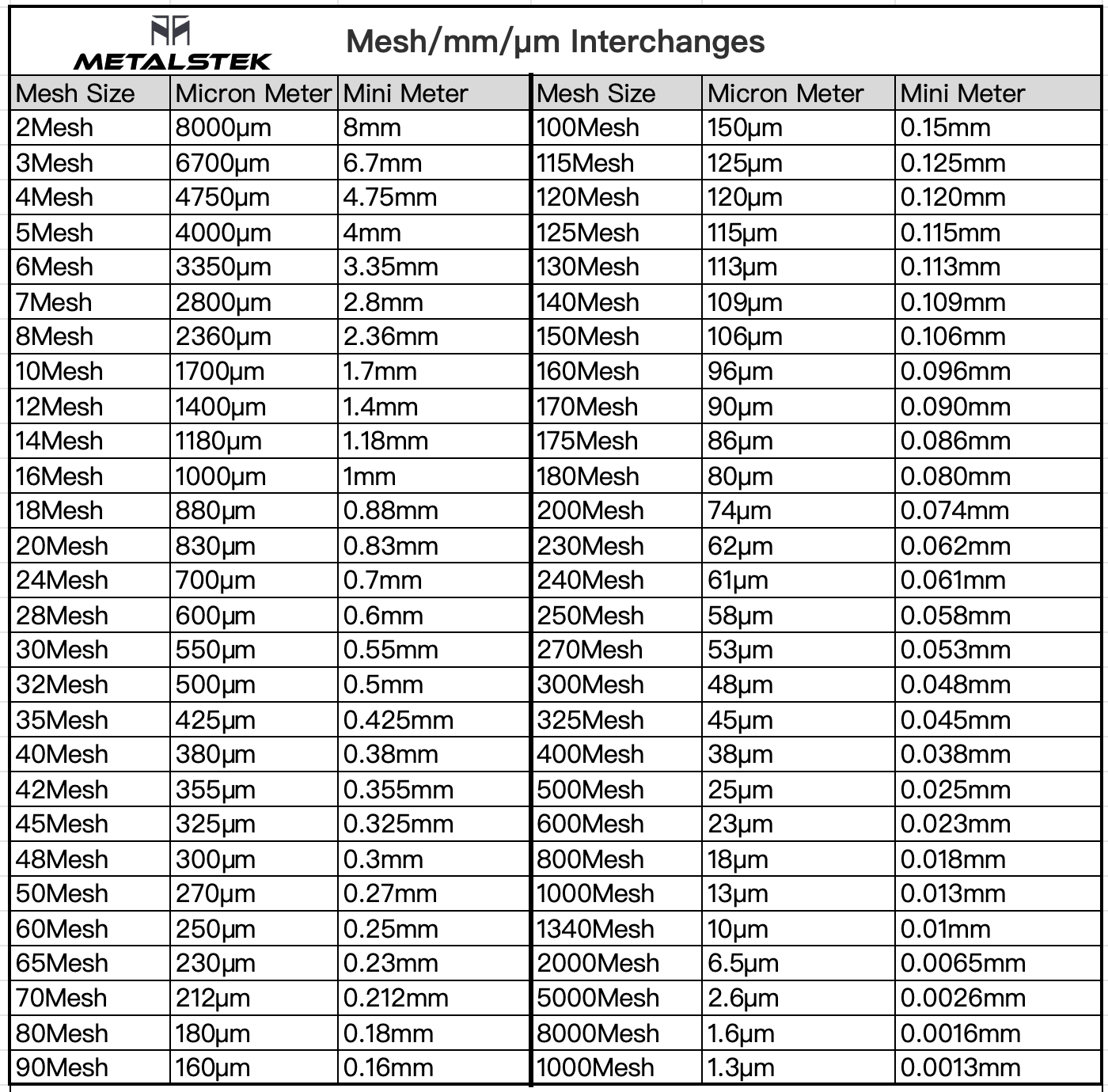

Classified by particle size, tungsten powder can be divided into Tungsten Ultra-fine Powder / Nano Powder, Tungsten Fine Powder/ Micro Powder, and Tungsten Coarse Powder (refer to the Tungsten Powder Grades Above).

Here’s an overview of different types of tungsten powder:

Tungsten powder has extensive application in producing weight fillers, radiation shielding fillers, and induction accelerators.

The thin film surface of its polymer mixture is exceptionally well-suited for radiation protection. Its large particle size makes it an ideal heavy metal filler for injection-molding applications. The distinctive shape and resulting high flowability of the particles make it well-suited for applications in the metal spray industry.

Additionally, Tungsten powder plays a crucial role in producing Tungsten Carbide powder, contributing to the preparation of cemented carbide tools for turning, milling, drilling, and molds, among other applications.

Sealed plastic bag within an iron drum bucket. Our Tungsten Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.