Menu

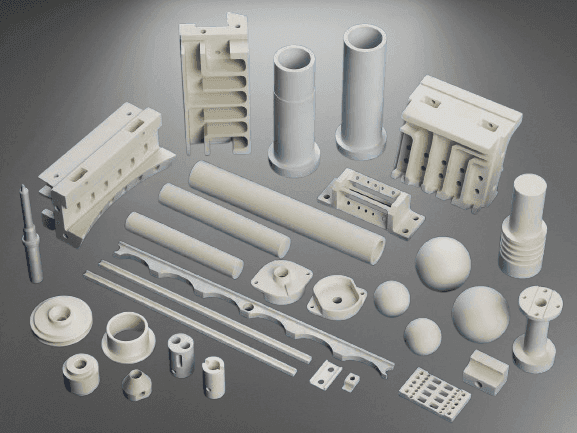

MetalsTek Engineering is at the forefront of providing high-quality Zirconia Ceramic Parts, showcasing a commitment to precision engineering and advanced materials. Renowned for its excellence, MetalsTek Engineering ensures that Zirconia Ceramic Parts meet the stringent demands of various industries.

Material: Zirconia, Yttrium Stabilized Zirconia

Compositions: Can be Customized

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: Zirconium Oxide (ZrO2), Yttria Stabilized Zirconia

Compositions: 94.9% ZrO2 + 5.1%Y2O3

Other: Mortar + Pestle; Pestle Replacement; Tailored Sizes

Application: Grinding, Pulverizing, Catalysis, Chemical Synthesis, Pharmacy

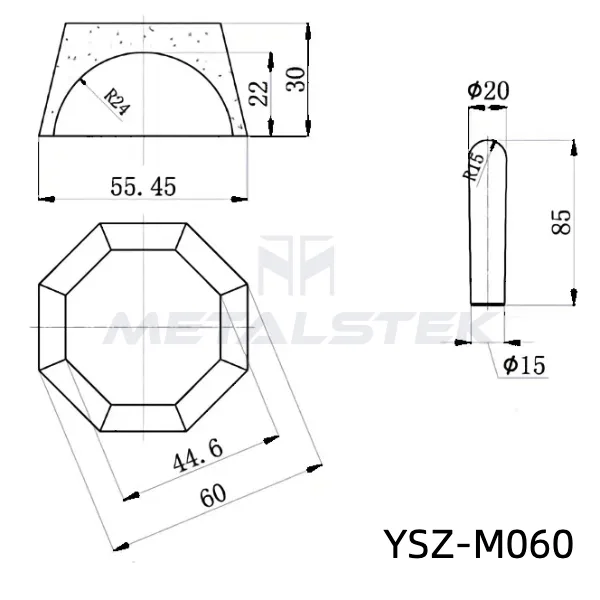

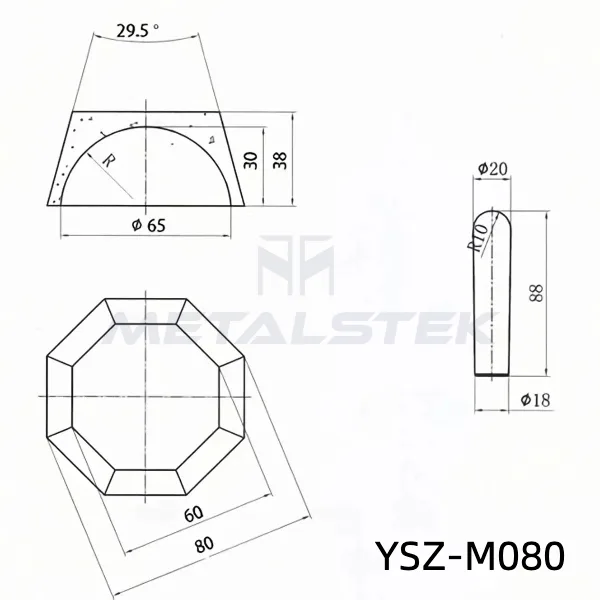

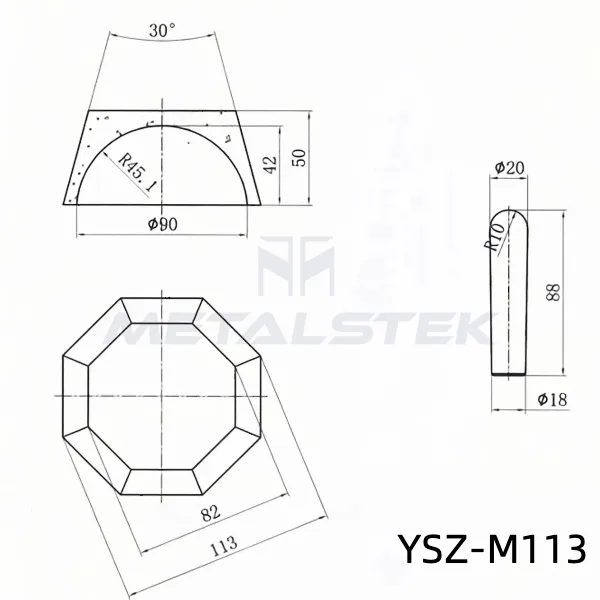

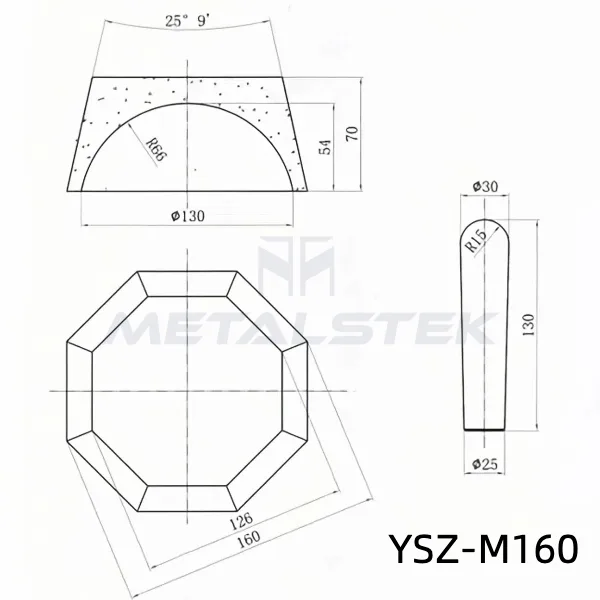

Dimensions: Outer Diameter 60mm, 80mm, 100mm, 113mm, 120mm, 160mm, or Customized (as shown below, mm)

| Composition (wt%) | 94.9% ZrO2 + 5.1%Y2O3 |

| Bulk Density (kg/L) | 3.5 |

| Specific Density (g/cm3) | > 6.0 |

| Hardness(HV) (GPa) | > 10 |

| Modulus of Elasticity (GPa) | 200 |

| Crushing Load (K.N.) | > 15 |

| Thermal Conductivity (W/m.K) | 3 |

| Thermal Expansion Coefficient (10×10-6/k at 20 to 400) | 9.6 |

Material: Zirconia, Yttrium Stabilized Zirconia

Type: Tube, Stud, Rod, or Customised

Purity: 95%, 99%, 99.9%, can be customized

Temperature: 1,600℃ Operation Temp.

Sizes: Tailored Sizes

Surfaces: Smooth Surfaces, 0.4µm Contact End Surfaces

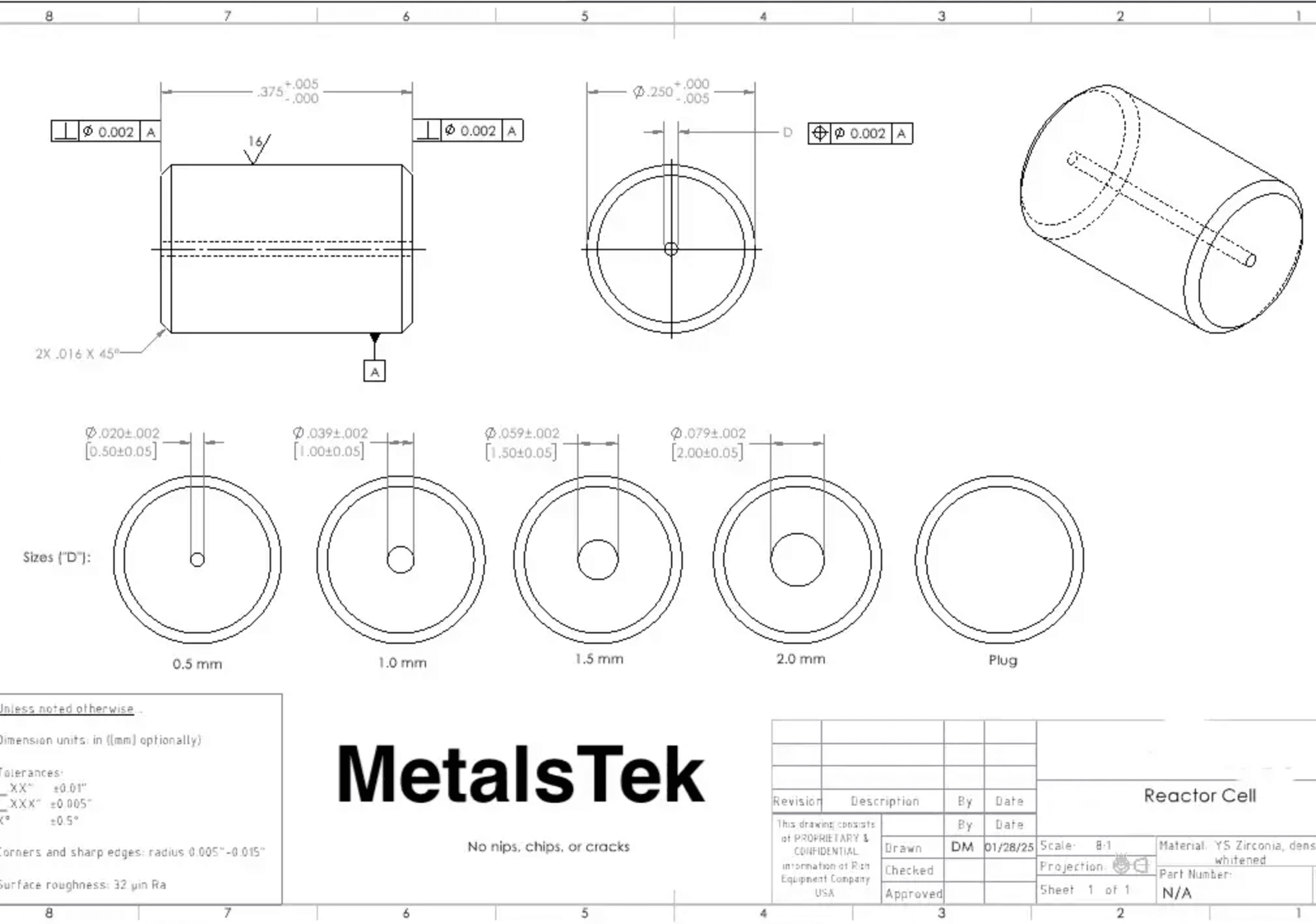

Uses: Serves as a reaction chamber, analytical instruments and electrochemical testing

A Zirconia Reactor Cell is a precision ceramic component manufactured from high-purity zirconium dioxide (ZrO₂). Zirconia is known for its exceptional strength, high fracture toughness, and superior thermal and chemical stability compared to most other ceramics.

Uses

Commonly applied in analytical instruments and electrochemical testing (fuel cells, solid oxide cells).

Serves as a reaction chamber for processes requiring resistance to high temperatures, aggressive chemicals, or corrosive environments.

Utilized in R&D labs and industrial testing equipment where accurate and reliable reaction conditions are required.

Key Features

High temperature resistance (up to 1000–1500 °C, depending on design).

Excellent corrosion and chemical resistance, ideal for acids, alkalis, and oxidizing environments.

High mechanical strength and toughness, reducing risk of cracking or failure.

Low thermal conductivity and high ionic conductivity, useful in electrochemical and energy applications.

Precision machinability: zirconia can be made into complex geometries with tight tolerances.

Material: Zirconia, Yttrium Stabilized Zirconia

Type: Crucible, Dish, Pan, Boat, Customised

Shape: Conical, Cylindrical, Pan, or Customized Shape

Purity: 95%, 99%, 99.9%, can be customized

Temperature: 1,600℃ Operation Temp.

Sizes: Tailored Sizes

Capacities: 3mL~1,500mL

Item Code | Top OD (mm) | Bottom OD (mm) | H(mm) | WT(mm) | C.C(ml) |

AC0925-TW005 | 25 | 15 | 28 | 1.3 | 5 |

AC0925-TW010 | 29 | 18 | 34 | 1.5 | 10 |

AC0925-TW015 | 32 | 23 | 33 | 1.5 | 15 |

AC0925-TW020 | 36 | 23 | 41 | 1.7 | 20 |

AC0925-TW025 | 36 | 25 | 42 | 1.7 | 25 |

AC0925-TW030 | 38 | 25 | 45 | 1.7 | 30 |

AC0925-TW040 | 45 | 30 | 46 | 2 | 40 |

AC0925-TW050 | 48 | 30 | 52 | 2 | 50 |

AC0925-TW070 | 58 | 33 | 66 | 2 | 70 |

AC0925-TW100 | 58 | 35 | 68 | 2 | 100 |

AC0925-TW150 | 67 | 42 | 78 | 2.5 | 150 |

AC0925-TW200 | 73 | 44 | 86 | 2.5 | 200 |

AC0925-TW250 | 79 | 46 | 96 | 2.5 | 250 |

AC0925-TW300 | 83 | 50 | 106 | 2.5 | 300 |

AC0925-TW400 | 91 | 56 | 108 | 2.5 | 400 |

AC0925-TW500 | 100 | 60 | 118 | 3 | 500 |

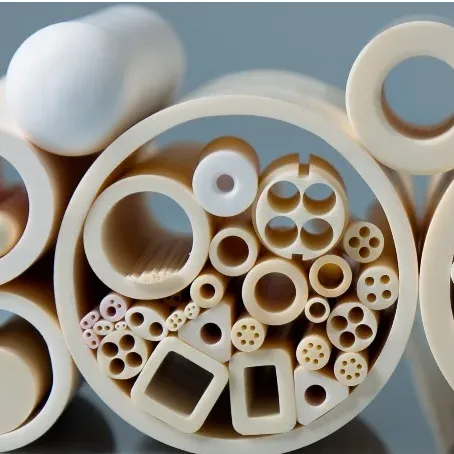

• Making parts for CVD, ion implants, photolithography, and semiconductor parts.

• Ideal for products such as injector tubes, gas nozzles, and insulators in traditional industries.

• Material for industrial furnaces.

• Protector for high-temperature thermal couples.

• Material for the chemical industry due to its high corrosion resistance.

Material: Zirconia, Yttrium Stabilized Zirconia

Shape: Tube, Square Tube, Multi-bore Tube, Custom Shapes

Purity: 95%, 99%, 99.9%, can be customized

Sizes: Tailored Sizes

Zirconia, also known as Zirconium Oxide, is a highly versatile material widely used for its strength, thermal stability, and resistance to wear and corrosion. Below are key applications where complex Zirconia shapes shine:

Zirconia is indispensable in aerospace for components that demand exceptional durability and resistance to extreme conditions. Common applications include nozzles, insulators, and structural supports where high strength and thermal stability are critical.

In the medical field, Zirconia is used for its biocompatibility and resilience. Applications include dental prosthetics, hip replacements, and surgical instruments, offering resistance to wear, corrosion, and sterilization processes.

Semiconductor fabrication relies on Zirconia’s purity and electrical insulation properties. Its uses include wafer carriers, insulators, and substrates that can withstand high temperatures and exposure to corrosive chemicals.

Zirconia provides excellent dielectric strength, making it ideal for insulators, substrates, and heat sinks in electrical and electronic devices. These components ensure stability and reliability in demanding applications.

In chemical industries, Zirconia is used for catalyst supports, reaction vessels, and protective liners. Its ability to resist high temperatures and corrosive environments makes it an ideal material for chemical processing equipment.

Zirconia’s exceptional hardness is perfect for industrial wear-resistant parts, including pump seals, valve seats, and bearing components. These parts endure abrasive conditions for extended periods, minimizing maintenance needs.

In high-temperature environments like furnaces, kilns, and heat treatment equipment, Zirconia serves as an effective thermal insulator. It offers excellent thermal shock resistance and long-term stability under extreme conditions.

Zirconia’s precision and heat resistance make it a preferred material for optical and laser systems. Applications include lenses, reflectors, and supports that demand stable performance and high-temperature durability.

Power generation equipment, such as nuclear reactors, turbines, and fuel cells, incorporates Zirconia components for their thermal stability, corrosion resistance, and mechanical strength under challenging conditions.

In the automotive sector, Zirconia is used for sensors, spark plugs, and exhaust systems. Its ability to endure high temperatures and mechanical stress ensures reliable performance in harsh environments.

Laboratory and analytical equipment, including crucibles, sample holders, and mixing tools, benefit from Zirconia’s chemical inertness and superior high-temperature performance.

Zirconia plays a critical role in environmental and water treatment, offering long-term durability in components that handle corrosive fluids and gases, even in the harshest conditions.

These diverse applications highlight why Zirconia is a top choice across industries. Its remarkable properties make it an essential material for advanced technologies and industrial innovations.

For more details about Zirconia complex shapes or to request custom solutions, visit MetalsTek or contact us at sales@metalstek.com.

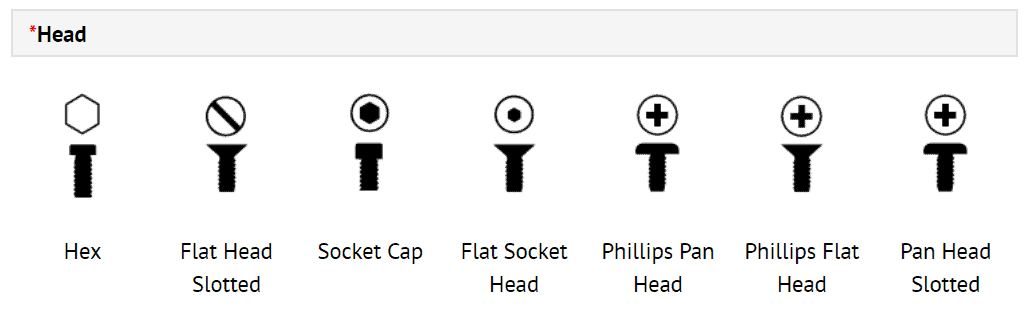

Material: Zirconia, Yttrium Stabilized Zirconia

Purity: 95%, 99%, 99.9%, can be customized

Sizes: M2, M2.5, M3, M4, M5, M6, M8, M10, Tailored Sizes

Length: 3~100mm, Metric and Imperial

Other Materials:

Boron Nitride / Pyrolytic boron nitride / Silicon Carbide (98% 99.5%) / Silicon Nitride / Boron Carbide / Alumina

Material: Zirconia, Yttrium Stabilized Zirconia Ceramic

Purity: 95%, 99%, 99.9%, can be customized

Shape: Cylinder, Rod, Bar, Square Bar, Customized Shapes

Size: Tailored Sizes

Other Ceramic Materials:

Boron Nitride / Pyrolytic boron nitride / Silicon Carbide (98% 99.5%) / Silicon Nitride / Boron Carbide / Alumina

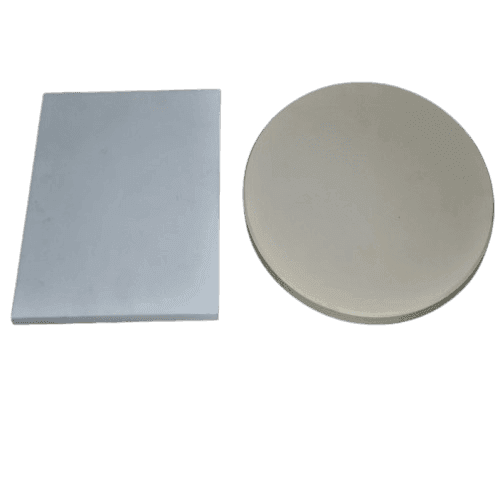

Material: Zirconia, Yttrium Stabilized Zirconia

Purity: 95%, 99%, 99.9%, can be customized

Density: 3.6~3.9 g/cc

Shape: Plate, Disc, Irregular Shapes, or Customized

Size: Tailored Sizes

Other Ceramic Materials:

Boron Nitride / Pyrolytic boron nitride / Silicon Carbide (98% 99.5%) / Silicon Nitride / Boron Carbide / Alumina

Material: Zirconia, Yttrium Stabilized Zirconia

Purity: 95%, 99%, 99.9%, can be customized

Shape & Dimensions: Per Your Drawing

Other Ceramic Materials:

Boron Nitride / Pyrolytic boron nitride / Silicon Carbide (98% 99.5%) / Silicon Nitride / Boron Carbide / Alumina

Zirconia, also known as zirconium oxide (ZrO2), is a versatile ceramic material used in various machinery parts and industrial applications. The key features of Zirconia include High strength and toughness, wear resistance, low thermal conductivity, good chemical resistance, and custom machining capability.

Some of the specific applications and products related to zirconia ceramic parts include:

These applications showcase the versatility of zirconia in aerospace, automotive, electronics, medical, and industrial manufacturing as it offers excellent wear resistance, high precision, and is suitable for high-temperature and corrosive environments.