Menu

MetalsTek Engineering is a premier supplier of top-notch Zirconium Products, encompassing Tubes, Pipe Fittings, Wire, Evaporations, Sputtering Targets, and more. Our unwavering dedication to precision engineering and stringent quality control guarantees that our zirconium offerings meet the exacting standards of diverse industrial applications.

Purity: Zr 99.95%

Properties: 6.5 g/cc Density, 1,885C M.P.

Size Range: Diameter 20~40mm, Can be Customized

Features: High Melting Point, Corrosion Resistance, Absorption for Neutrons, Biocompatible

Main Applications: Nuclear Power, Chemical Industry, Medicals, Electronics, Optical

Purity: Zr 99% Min

Type: Industrial grade, Metallurgy Grade

Properties: 6.5 g/cc Density, 1,885C M.P.

CAS#: 7440-67-7

Applications: Civilian Power Reactor, Powdered Aircraft, Nuclear Submarines

| Grade | Zr+Hf | Hf | Ni | Cr | Al | Mg | Si | O | N | Cl | C | Fe+Cr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Zr-S1 | 99.4 | <3.0 | 0.01 | 0.02 | 0.01 | 0.06 | 0.01 | 0. 10 | 0.01 | 0.13 | 0.05 | – |

| Zr-S2 | 99.2 | <4.5 | – | – | – | – | – | 0.14 | 0.025 | – | 0.05 | 0.2 |

Introduction:

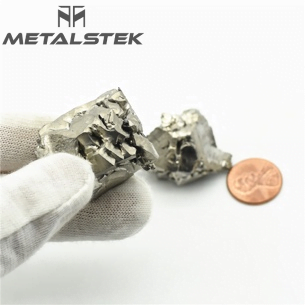

Zirconium Sponge, resembling silver metal with a steel-like appearance, finds primary use in manufacturing chemical corrosion-resistant equipment, the electronics industry, pipeline valve materials, special high-strength and high-temperature alloy materials, as well as electric vacuum and lighting bulb industry getters.

Key Properties:

Applications:

Purity: Zr 99%~99.95%

Properties: 6.5 g/cc Density, 1,885C M.P.

Form: Powder, Pellets, Granules

Other: Highly Customized

Zirconium is a highly versatile metal known for its exceptional corrosion resistance and high-temperature properties, making it invaluable in various industrial applications. It is widely used in the chemical industry, where corrosive conditions are prevalent, and its low neutron absorption and high-temperature performance make it a vital material in constructing nuclear reactors. Additionally, zirconium is utilized in various industries, including aerospace, automotive, and medical equipment manufacturing. Its corrosion resistance and biocompatibility make it an ideal material for various medical applications, such as surgical appliances and medical devices. Zirconium’s unique combination of properties also makes it suitable for use in jet engine linings and as an alloying element to improve the mechanical properties of alloys.

| Al | 48 | In | <0.05 | Re | <0.05 |

| As | <0.05 | Ir | <0.05 | Rh | <0.5 |

| Au | <0.05 | K | 0.25 | S | 16 |

| B | 0.07 | La | <0.013 | Sb | <0.5 |

| Bi | 0.28 | Mg | 0.09 | Sc | 0.6 |

| Br | 0.039 | Mn | 0.2 | Se | <0.05 |

| Ca | 0.33 | Mo | 3.7 | Si | 35 |

| Ce | 0.021 | Na | 0.3 | Sm | <0.05 |

| Cl | 1.6 | Nb | 1.7 | Sn | 16 |

| Co | 0.032 | Nd | <0.05 | Sr | 0.009 |

| Cr | 3.4 | Ni | 3.3 | Ta | 0.66 |

| Cu | 0.16 | Os | <0.05 | Te | <0.5 |

| F | 1.7 | P | 0.35 | Ti | 36 |

| Fe | 51 | Pb | 0.96 | U | 1.1 |

| Ga | 0.1 | Pd | <5 | V | 0.13 |

| Ge | <0.05 | Pr | 0.036 | W | 1.3 |

| I | <0.5 | Pt | <0.05 | Zn | 0.28 |

Our Zirconium Products are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.