Menu

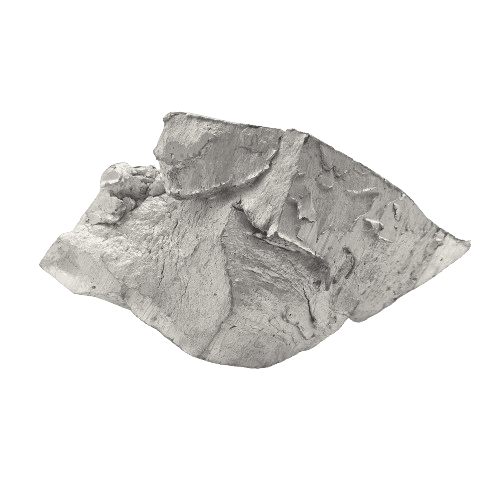

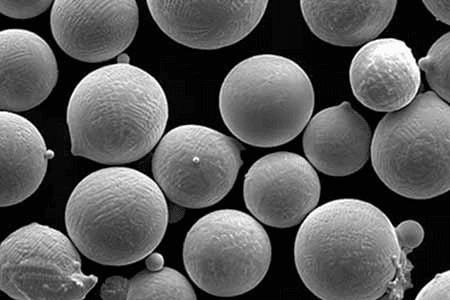

MetalsTek Engineering is a trusted supplier of Aluminum Metals. We have a large inventory of Aluminum Metals in various forms, such as powder, grains, pellets, ingots, Wire sheets, plate, rod, etc.

Material: Pure Aluminum

Purity: Al 99.9%~99.999%

Form: Powder, Granules, Pellets, Chunks, Ingots

Size: Tailored Size

MOQ: US$200.00

Material: Aluminum, 99.9%~99.9995%

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Aluminum is a chemical element represented by the symbol Al and has an atomic number of 13. It is the third most abundant element and the most abundant metal in the Earth’s crust. Aluminum has a silvery-white appearance and is well-known for being lightweight, durable, and resistant to corrosion. The reason for its resistance to corrosion is because of a thin layer of aluminum oxide that forms on its surface when exposed to air.

Aluminum has a density of approximately 2.7 g/cm³, a melting point of 660.32°C (1,220.58°F), and a boiling point of 2,467°C (4,472.6°F). This makes it significantly lighter and less dense than other commonly used metals like iron or copper. Due to its unique combination of properties such as low density, high strength, and recyclability, aluminum is widely used in various industries including aerospace, automotive, construction, and packaging.

Aluminum is widely used due to its lightweight, high strength-to-weight ratio, corrosion resistance, and electrical and thermal conductivity. It is also recyclable. Its key applications include:

Our Aluminum Metals are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.

Aluminium, the unsung hero of the metals, is taking center stage in various industries. From aerospace to construction, this versatile material has proved its worth, offering a perfect balance of strength, durability, and lightweight properties. No wonder it has catapulted itself to become one of the most sought-after metals in the market today.

In this article, we delve into the wonders of aluminium, exploring its rise and shine in different sectors. We unlock the reasons behind its immense popularity, showcasing why it has become the go-to material for innovative designs, high-performance applications, and sustainable solutions.

With input from experts in the field, we highlight the incredible features of aluminium and how they contribute to overcoming engineering challenges. From its outstanding thermal and electrical conductivity to its resistance against corrosion, aluminium truly stands out as the ultimate choice for modern manufacturing and design.

Join us as we dig deeper into the world of aluminium, uncovering its remarkable qualities and untapped potential. Get ready to be amazed by the versatility and impact of this extraordinary metal.

The history of aluminium production is a tale of perseverance, innovation, and industrial breakthroughs. Discovered in the 19th century by Sir Humphry Davy, aluminium was initially considered a precious metal due to the complexity of its extraction process. It wasn’t until the invention of the Hall-Héroult process in 1886 by Charles Martin Hall and Paul Héroult that aluminium production became commercially viable. This revolutionary method allowed for the mass production of aluminium, transforming it from a rare metal to a ubiquitous material found in everyday objects. Today, aluminium is produced on a massive scale, with modern refinements in technology further streamlining the manufacturing process, making it more efficient and cost-effective.

The Properties and Characteristics of Aluminium

Aluminium possesses a unique set of properties that set it apart from other metals. With a low density and high strength-to-weight ratio, aluminium is an ideal choice for applications where weight reduction is critical, such as in the aerospace industry. Additionally, aluminium exhibits excellent corrosion resistance, making it suitable for outdoor structures and marine environments. Its malleability and ductility allow for easy shaping and forming, enabling intricate designs and complex structures to be realized. Furthermore, aluminium is a superb conductor of heat and electricity, making it indispensable in electrical transmission lines and heat exchangers. These exceptional characteristics make aluminium a versatile and indispensable material in a wide range of industries.

The versatility of aluminium lends itself to a myriad of applications across diverse industries. In the automotive sector, aluminium is increasingly used to reduce vehicle weight, enhance fuel efficiency, and improve performance. The construction industry harnesses the strength and durability of aluminium in the form of building facades, roofing systems, and structural components. In the packaging industry, aluminium’s impermeability to light, moisture, and gases makes it an ideal choice for food and beverage containers. The aerospace industry relies heavily on aluminium for aircraft components, owing to its lightweight properties and high strength. From consumer electronics to renewable energy systems, aluminium finds its way into countless products, underscoring its universal appeal and adaptability.

While aluminium boasts impressive mechanical properties and functional versatility, its production comes with environmental considerations. The extraction of aluminium from bauxite ore consumes significant energy, contributing to greenhouse gas emissions and resource depletion. The refining process also generates waste products that can pollute water sources and harm ecosystems if not managed properly. However, advancements in sustainable practices, such as recycling and energy-efficient smelting techniques, are reducing the environmental footprint of aluminium production. By prioritizing recycling and adopting cleaner technologies, the aluminium industry is working towards a more sustainable future, minimizing its impact on the planet while meeting the growing demand for this valuable metal.

Aluminium’s myriad advantages make it a preferred material for various applications, but it also comes with certain limitations. On the positive side, aluminium is lightweight, corrosion-resistant, and highly formable, making it ideal for structures requiring strength and durability without added bulk. Its excellent thermal conductivity and recyclability further enhance its appeal in diverse industries.

However, aluminium’s lower stiffness compared to steel can be a drawback in certain load-bearing applications where rigidity is crucial. Additionally, aluminium’s initial cost may be higher than some traditional materials, although its long-term benefits often outweigh the upfront investment. Understanding the balance between the advantages and limitations of aluminium is essential for making informed decisions in material selection and design.

The realm of aluminium technology is constantly evolving, driven by innovation and research breakthroughs that push the boundaries of what this remarkable metal can achieve. New alloy formulations and processing techniques are enhancing the mechanical properties and performance of aluminium, opening up new possibilities for lightweight structures and high-stress applications.

Nanotechnology is being employed to tailor the microstructure of aluminium at the atomic level, resulting in materials with superior strength and enhanced properties. Additive manufacturing, or 3D printing, is revolutionizing the production of complex aluminium components, offering design freedom and rapid prototyping capabilities. As technology continues to advance, the future of aluminium holds exciting prospects for sustainable materials, advanced applications, and groundbreaking solutions across industries.

One of the most significant advantages of aluminium is its recyclability, with nearly 75% of all aluminium ever produced still in use today. Recycling aluminium requires only a fraction of the energy needed to extract it from ore, making it a highly eco-friendly option compared to primary production. The closed-loop nature of aluminium recycling ensures that the material can be repurposed repeatedly without compromising its quality or performance. By promoting a circular economy approach, where aluminium is collected, recycled, and reused efficiently, we can conserve resources, reduce waste, and decrease carbon emissions. Embracing aluminium recycling is not just environmentally responsible but also economically beneficial, creating a sustainable supply chain that supports a greener future.

As we conclude our exploration of the wonders of aluminium, it is evident that this versatile metal holds immense promise for the future of engineering, design, and sustainability. With its exceptional properties, wide-ranging applications, and environmental advantages, aluminium continues to shape industries and inspire innovations around the world. The ongoing emphasis on recycling, sustainability, and technological advancements bodes well for aluminium’s role in a circular economy and a greener planet. By harnessing the full potential of aluminium and embracing its endless possibilities, we can build a brighter, lighter, and more resilient future where this extraordinary metal shines ever brighter. Join the aluminium revolution and be part of a transformative journey towards a world where innovation meets sustainability, powered by the rise and shine of aluminium.

—

This comprehensive article has explored the multifaceted world of aluminium, from its historical origins to its modern-day applications and future prospects. Through understanding the properties, advantages, and challenges of aluminium, we gain a deeper appreciation for this remarkable metal and its pivotal role in shaping our technological landscape. As we continue to unlock the wonders of aluminium and harness its potential for sustainable innovation, we pave the way for a brighter, more resilient future where this versatile material shines as a beacon of progress and possibility. Let us embrace the rise and shine of aluminium as we embark on a journey towards a more sustainable and aluminium-enriched world.