Menu

MetalsTek Engineering is a professional supplier of Aluminum Powders, including its Spherical Powder, Nano Power, Micro Powder, and Atomized Powder.

Material: Aluminum

Purity: Al 95%~98%

Mesh Size: 8~500 Mesh

Applications: Metallurgy, Fireworks, Explosion Material, etc.

Grade | Al | Active Al | Impurities, Max. | |||

>% | >% | Fe | Si | Cu | H2O | |

FLPA2500 | 98 | / | 0.5 | 0.5 | 0.1 | 0.2 |

FLPA1000 | 98 | / | 0.5 | 0.5 | 0.1 | 0.2 |

FLPA630 | / | 97 | 0.5 | 0.5 | 0.1 | 0.2 |

FLPA500 | 98 | / | 0.5 | 0.5 | 0.1 | 0.2 |

FLPA450 | / | 97 | 0.5 | 0.5 | 0.1 | 0.2 |

FLPA280 | / | 95 | 0.5 | 0.5 | 0.1 | 0.1 |

FLPA250 | / | 96 | 0.5 | 0.5 | 0.1 | 0.2 |

FLPA180 | / | 95 | 0.5 | 0.5 | 0.1 | 0.1 |

FLPA160A | 98 | / | 0.5 | 0.5 | 0.1 | 0.2 |

FLPA160B | / | 95 | 0.5 | 0.5 | 0.1 | 0.1 |

FLPA140 | / | 96 | 0.5 | 0.5 | 0.1 | 0.2 |

FLPA125 | 98 | / | 0.5 | 0.5 | 0.1 | 0.2 |

FLPA80 | 98 | / | 0.5 | 0.5 | 0.1 | 0.2 |

Grade | Particle Size Distribution | A.D. g/cm3 (Min) | Application | |

μm | % (Max) | |||

FLPA2500 | ≥2500 | 0.3 | / | Metallurgy and Special Iron Alloy |

<200 | 15 | / | ||

FLPA1000 | ≥1000 | 0.3 | / | |

<200 | 15 | / | ||

FLPA630 | ≥630 | 0.3 | 0.96 | Firework and Explosion Material |

≥450 | 12 | |||

<250 | 20 | |||

FLPA500 | ≥500 | 0.3 | / | Metallurgy |

FLPA450 | ≥450 | 0.3 | 0.96 | Firework and Explosion Material |

≥250 | 10 | |||

<140 | 20 | |||

FLPA280 | ≥280 | 10 | 0.96 | Firework and Welding Material |

<180 | 40 | |||

FLPA250 | ≥250 | 0.3 | 0.96 | Firework and Explosion Material |

≥160 | 10 | |||

<100 | 30 | |||

FLPA180 | ≥180 | 10 | 0.96 | Firework, Friction and Welding Material |

<140 | 45 | |||

FLPA160A | ≥160 | 0.3 | / | Metallurgy and Chemical |

FLPA160B | ≥160 | 10 | 0.96 | Firework and Chemical |

<125 | 50 | |||

FLPA140 | ≥140 | 0.3 | 0.97 | Welding Material and Explosion Material |

<100 | 15 | |||

FLPA125 | ≥125 | 0.3 | / | Chemical and Refractory |

FLPA80 | ≥80 | 5 | / | Refractory |

Applications

Material: Aluminum

Purity: Al 99.99% (Metal Basis 99%)

Density: 2.7 g/cc

Mesh Size: 8~200 Mesh

Applications: Fireworks, Explosions, Slurry, Detonators, Sparkles, etc.

Material: Aluminum, 7429-90-5

Purity: Al 99.9% (Metal Basis 99%)

Melting Point: 660℃

Mesh Size: 1,000μm, Nearly Spherical

Specific Surface Area: 9 m2/g

Applications: Fireworks, Explosions, Electronics, Paints, etc.

Material: Aluminum, 7429-90-5

Purity: Al 99.9% (Metal Basis 99%)

APS: 50nm, Nearly Spherical

Specific Surface Area: 20 m2/g

Applications: Fuel Additives, Sintering Additive, Metal Pigments, Metallurgy etc.

Aluminum Powder is a finely ground form of aluminum metal, typically produced through the process of atomization or mechanical grinding. It is characterized by its fine particle size and high reactivity, making it suitable for a wide range of applications across industries such as aerospace, automotive, construction, and pyrotechnics. Aluminum Powder is commonly used as a fuel in solid rocket propellants, as an additive in paints, coatings, and pigments, and in the production of aluminum-based alloys and composites.

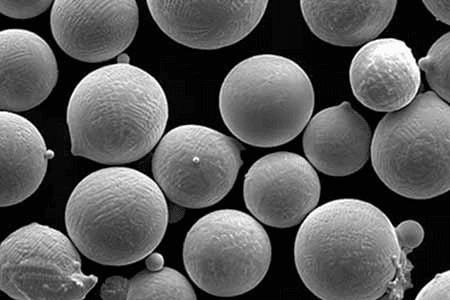

Spherical Aluminum Powder, on the other hand, is a specialized form of Aluminum Powder characterized by its spherical particle morphology. It is typically produced through atomization techniques that yield uniformly shaped particles with high sphericity and surface smoothness. Spherical Aluminum Powder offers improved flowability, packing density, and compressibility compared to irregularly shaped powders, making it particularly well-suited for applications such as additive manufacturing (3D printing), metal injection molding (MIM), and thermal spray coatings. Additionally, spherical aluminum powder is utilized in explosive formulations, where its uniform particle size distribution contributes to consistent performance and safety.

Aluminum Powders, with their versatile properties, find widespread applications across various industries. Some key applications include:

These diverse applications highlight the importance of Aluminum Powders in modern manufacturing, construction, and technology industries, contributing to advancements in materials science, engineering, and innovation.

Our Aluminum Powder is clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.