Menu

With an unwavering commitment to excellence, MetalsTek Engineering delivers high-purity Copper Powders to clients worldwide.

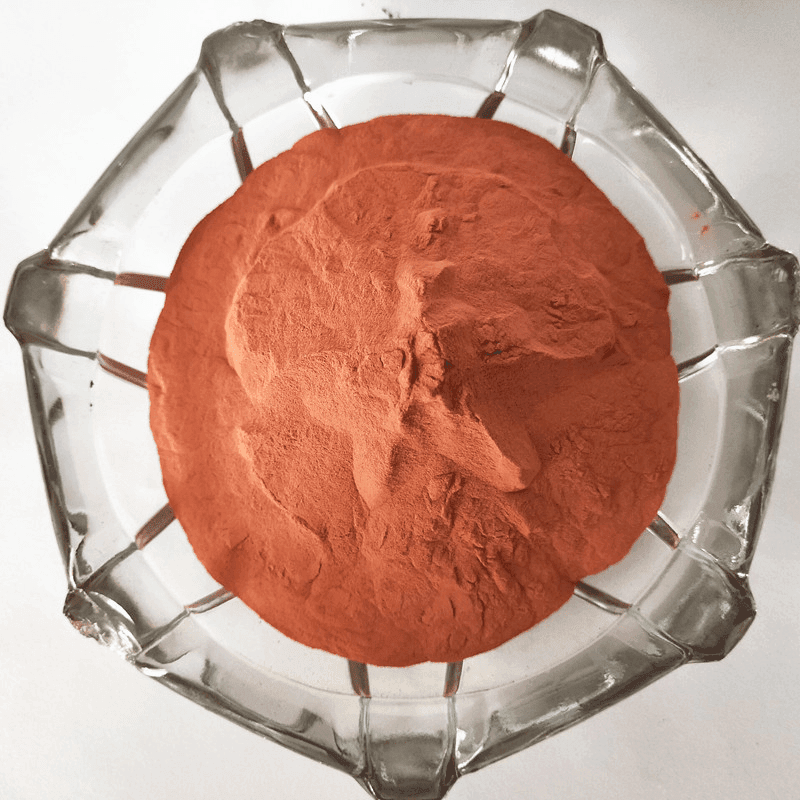

Materials: Copper

Purity: 98%~99.9999%

Properties: Reddish Lustrous, 1,083°C M.P., 8.92 g/cc Density

Form: Powder, Spherical Powder

Size: Tailored Sizes

Materials: Copper, Cu

Purity: 99.9%

Form: Spherical Powder

Size: 50nm, 300nm, 1µm, or Customized

Item | Particle Size | Purity (%) | Specific Area (m2/g) | Bulk Density (g/cm3) | Density (g/cm3) | Form | Color |

CP29S-50nm | 50nm | 99.9 | 15 | 0.2 | 8.9 | Spherical | Brown |

CP29S-300nm | 300nm | 99.9 | 4 | 1 | 8.9 | Spherical | Red Brown |

CP29S-1um | 1um | 99.9 | 2.5 | 7.5 | 8.9 | Spherical | Red Brown |

Materials: Copper, Cu

Purity: 99%~99.95%

Form: Spherical Gas Atomized

Size: -75 +31µm, -90 +38µm, or Customized

Materials: Copper, Cu

Compositions: Cu:99.5 Fe:0.02 Sb:0.01 S:0.004 Pb:0.05

Purity: 99.5%

Form: Spherical Powder

Size: 45μm, 53μm, 75μm, or Customized

Copper and copper compound powders exhibit a wide range of properties and applications across various industries. Copper powder is known for conferring nonsparking and fungicidal properties to oxychloride cements, while copper, lead, and zinc powders are used to coat petroleum drilling pipe threads. In paste form, copper and copper alloy powders serve as filler metals for brazing steel and copper alloy parts, offering controlled deposition and the ability to dispense in irregular shapes. These powders find applications in furnace brazing of carbon and alloy steel parts, stainless steels, and other metal alloys, with brazing temperatures typically around 2050°F (1,130°C). Additionally, copper powder acts as a catalyst in chemical operations, precipitating various metals from solutions while leaving others in solution.

Our Copper Powder is clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.

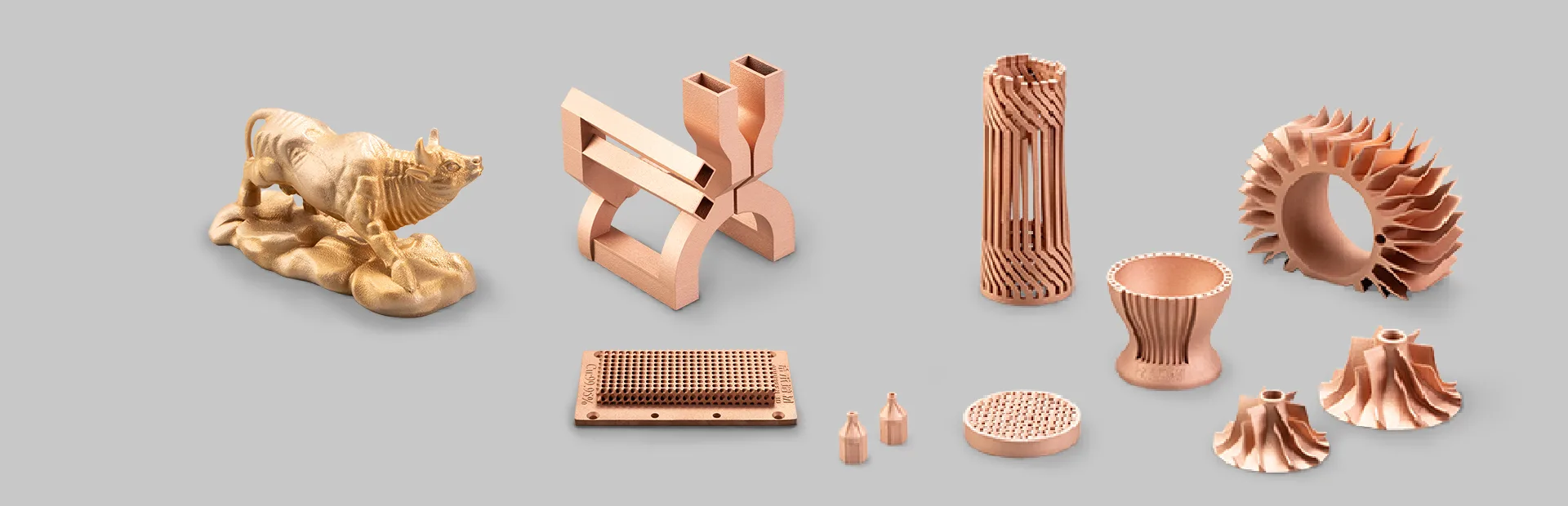

Imagine being able to print electronic components, heat exchangers, or even antimicrobial surfaces—all using copper-based powders in 3D printing. It’s not science fiction—it’s the future of additive manufacturing. The evolution of 3D printing technology has opened up new avenues for the use of copper in industries like electronics, aerospace, and healthcare, making copper-based powders essential for innovation.

In this article, we explore the different types of copper powder, copper oxide powder, and spherical copper powder, their key properties, and how they are shaping modern 3D printing processes.

To fully appreciate the value of copper in 3D printing, it’s important to understand its forms:

Copper Powder: Copper powder is available in varying purities (typically 99.9% to 99.999%), offering excellent thermal conductivity, electrical conductivity, and corrosion resistance. These properties make it ideal for high-performance components such as heat sinks, conductive circuit boards, and electromagnetic shielding.

Copper Oxide Powder: This form of copper is available as CuO (Copper(II) oxide) or Cu₂O (Copper(I) oxide). While copper oxide powder may not have the same conductivity as pure copper, it has a variety of other industrial applications. It’s especially useful for creating semiconductor coatings, catalysts, and optical thin films. Its distinctive properties also make it an ideal choice for solar energy systems and energy storage devices.

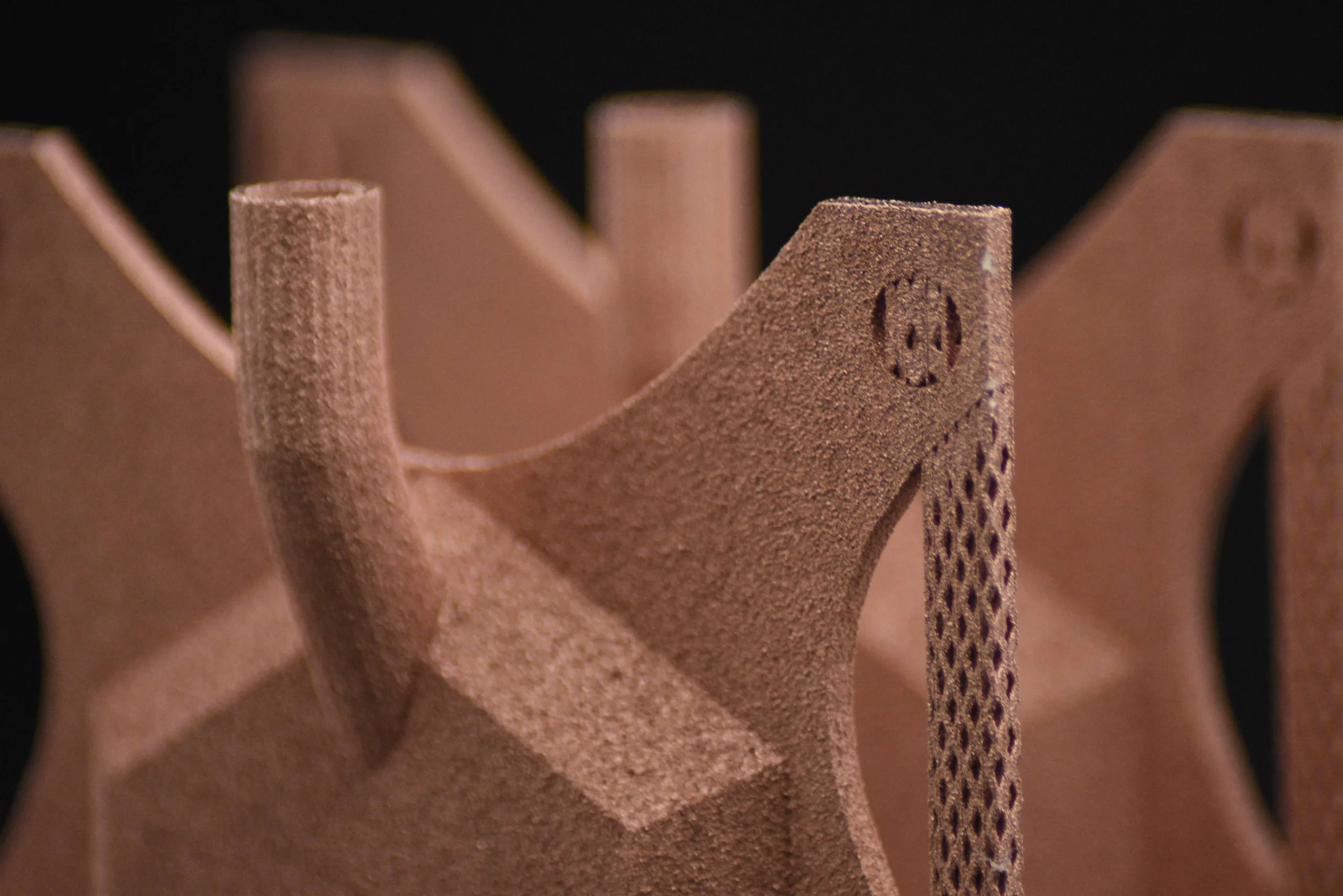

Spherical Copper Powder: When it comes to 3D printing, spherical copper powder takes center stage. This powder is preferred for powder bed fusion (PBF) and selective laser sintering (SLS) processes due to its high flowability and uniform size distribution. Spherical copper powder ensures that the layers in 3D-printed objects are perfectly formed, allowing for higher mechanical strength and greater precision in printed parts.

Why is copper such a game-changer in the world of additive manufacturing? Let’s dive into some of its unmatched benefits:

Superior Electrical and Thermal Conductivity: Copper’s unparalleled ability to conduct heat and electricity makes it ideal for producing electronic components that require these properties, such as heat exchangers, circuitry, and power transmission components.

Antibacterial Properties: Copper and its alloys have inherent antimicrobial qualities, which is a major asset in the medical field. Copper-based 3D printed parts can be used to create antibacterial surgical tools, implants, and prosthetics, improving patient outcomes by reducing the risk of infection.

Corrosion Resistance: Copper is naturally resistant to corrosion, which makes it perfect for applications in marine environments or industries where long-lasting, durable materials are essential.

Now, when it comes to 3D printing, spherical copper powder offers some unique advantages:

Higher Density for Better Mechanical Properties: The uniform spherical shape of the powder enables better packing density during the printing process, resulting in stronger, more durable printed parts.

Improved Flowability: Unlike irregular-shaped powders, spherical powders flow more easily, reducing the risk of clumping during printing and improving the overall consistency of each layer.

Uniform Layer Formation: The uniform size and shape of spherical powder particles allow for high-precision printing, reducing defects and ensuring the integrity of the finished part.

Copper-based powders are not just another material—they are transforming a wide range of industries through their applications in 3D printing:

Electronics: Copper powder is used to print heat sinks, conductive components, circuit boards, and antennas, which are all integral to modern electronic devices like smartphones, computers, and wearables.

Aerospace and Automotive: Copper is crucial for lightweight conductive components that are needed in aircrafts, satellites, and electric vehicles. Its combination of high strength, light weight, and conductivity makes it a top choice for these industries.

Biomedical Applications: Thanks to its antimicrobial properties, copper-based 3D printed parts are being used in the medical field to create implants, prosthetics, and surgical tools that help combat infections while offering functional performance.

Energy and Battery Industry: Copper-based electrodes are integral to developing next-generation batteries and fuel cells, driving advancements in energy storage and green energy technologies.

When selecting copper powder for your 3D printing applications, consider the following factors to ensure the best material for your project:

Purity: Copper powder comes in various purities, ranging from 99.9% to 99.999%. The higher the purity, the better the material’s performance, especially in high-tech applications like semiconductors or sensitive electronics.

Particle Size: Copper powder is available in a wide range of particle sizes. For nano-sized applications, such as thin films or advanced coatings, you would need fine powders. However, coarser powders are better suited for structural applications that require more mass.

Manufacturing Method: Copper powders can be produced using different methods like gas atomization, which produces high-quality spherical powders ideal for 3D printing, or water atomization, which can produce irregularly shaped powders.

The future of copper-based 3D printing looks bright, with innovations on the horizon:

Multi-metal Printing: The ability to combine copper with other metals, such as tungsten, tantalum, or titanium, is a game-changer. This could lead to the creation of complex multi-material components with tailor-made properties.

Next-Gen Sintering Techniques: Advances in sintering technologies are helping to reduce the oxidation challenges faced when printing with copper, allowing for more accurate and efficient production of copper-based parts.

Nano-Copper Powders: As nano-technology progresses, nano-copper powders are expected to revolutionize applications in electronics, medical devices, and energy systems due to their unique properties at the nanoscale.

Copper powder, copper oxide powder, and spherical copper powder are transforming industries by enabling new possibilities in 3D printing. Whether you’re in electronics, aerospace, biomedical, or energy, copper’s unparalleled properties make it the material of choice for high-performance 3D printed components.

As demand for advanced, custom products grows, MetalsTek can provide high-quality copper and copper oxide powders, as well as tailored solutions for your 3D printing needs. Stay ahead of the curve and discover how copper-based materials can bring your projects to life.