Menu

As a frontrunner in the field, MetalsTek Engineering provides cutting-edge Iron Powders tailored to meet the exacting demands of customers worldwide.

Material: Carbonyl Iron, CAS# 7439-89-6

Purity: ≥98%

APS: -200 +325 mesh≥ 95%, +325 mesh≤ 5%

Material: 8Ni300

Composition: Fe, Ni:17-19; Mo:4.5-5.2; Co:8.5-9.5; Ti:0.6-0.8; Al:0.05-0.15; Cr≤0.5; Si≤0.1; C≤0.03

Particle Size: 0-25,15-53,45-105,75-105μm

Flowability ≤18s, Density ≥4.2g/cc, O/N≤300ppm

Material: Fe2O3, Fe3O4, InFe2O4, CoFe2O4, NiFe2O4, ZnFe2O4

Purity: 99.9%

Particle Size: 80nm~1,000μm

Material: Iron Based Alloys

Composition: Can be Customized

Purity: 99%~99.99%

Particle Size: Tailored Sizes

Material: Iron Based Compounds

Composition: Can be Customized

Purity: 99%~99.99%

Particle Size: Tailored Sizes

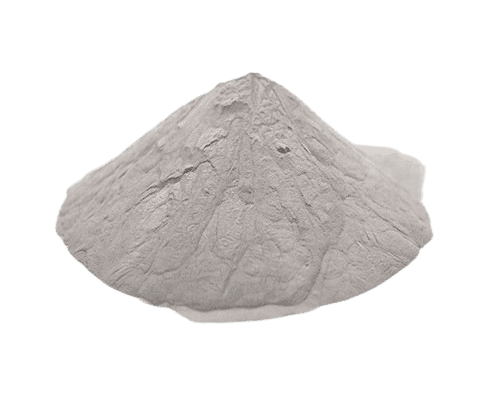

Iron Powder is a fine, grayish-black powder composed predominantly of elemental iron particles. It is produced through various methods, including reduction of iron oxide (such as hematite or magnetite) or by electrolysis. Iron Powder is available in different particle sizes, ranging from nanometers to micrometers, to several millimeters, depending on its intended application. Spherical Iron Powder, Carbonyl Iron Powder, Nano Iron Powder, Micron Iron Powder are the typical types.

The applications of Iron Powder span across diverse industries due to its unique properties and versatility. Here are some of the typical applications:

Iron Powder plays a vital role across multiple industries, contributing to the production of steel, magnetic materials, chemical compounds, protective coatings, and advanced manufacturing processes. Its diverse applications underscore its significance as a valuable material in modern industrial operations.

Our Iron Powders are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.