Menu

MetalsTek Engineering prides itself on delivering high quality Nickel Iron Alloys crafted with precision and expertise. We have Nickel Iron alloy in various forms, such as bars, powder, sheet, etc. Among the various compositions, grade 4750 is the famous star of NiFe alloy.

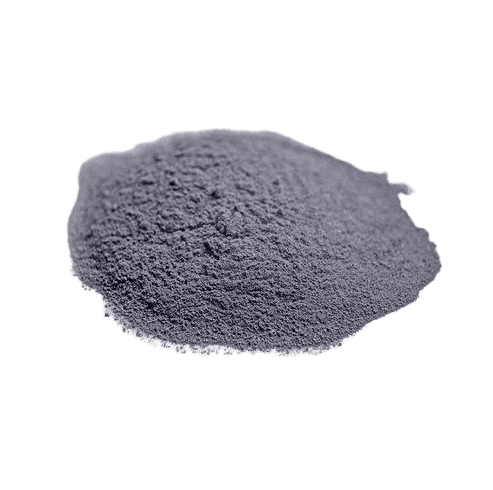

Material: Nickel Iron Alloy

Form: Spherical Powder

Particle Sizes: 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm, Customized

Applications: Medical Equipment, Defenses, Nuclear Industry, etc.

Material: Iron Nickel, 99.9%~99.99%

Composition: Can be Customized

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

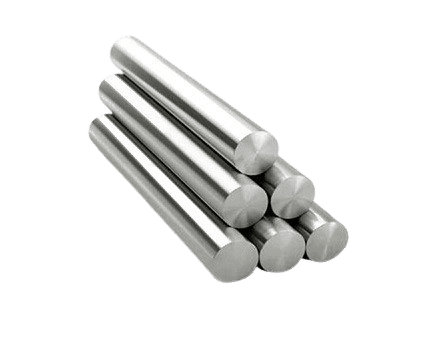

Material: Nickel Iron, Grade 4750

Shape: Rod, Bar

Size: Customized Sizes

Synonyms: High Perm 49, ASTM F30 4750 Electrical Alloy

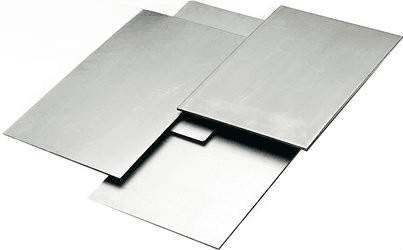

Material: Nickel Iron, Grade 4750

Shape: Foil, Sheet, Plate, Bar

Size: Customized Sizes

Synonyms: High Perm 49, ASTM F30 4750 Electrical Alloy

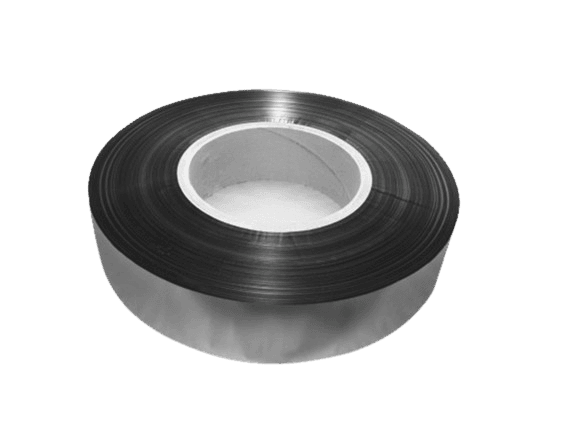

Material: Nickel Iron, Grade 4750

Shape: Foil, Strip, Tape

Size: Customized Sizes

Synonyms: High Perm 49, ASTM F30 4750 Electrical Alloy

Material: W-Ni-Fe

Purity: W 90%~97%

Density: 16.85~18.5g/cc

Form: Rod, Bar, Sheet, Plate, Customized

Material: HY-180 High Strength Alloy Steel

Composition: Fe78.72%, Ni10%, Co8%, Cr2%, Mo1%, C0.13%, Mn0.1%, Si0.05%

Density: 7.75g/cc

Form: Rod, Bar, Sheet, Plate, Machined Parts

Applications: Aerospace, Automotive, Defence, Vehicle Components, Structural Engineering, Industrial Machinery

Typical Industry Specification: vehicle components, structural engineering, industrial machinery, and aerospace structures

HY-180 is a premium-grade alloy steel, recognized for its outstanding strength, toughness, and wear resistance. With a carefully balanced composition and a production process optimized for performance, HY-180 offers unparalleled reliability for applications in heavy machinery, automotive, and other high-stress environments.

HY-180 alloy steel features a precise blend of elements, ensuring superior mechanical properties:

Available in a wide range of sizes and forms, including sheets, bars, rods, and custom-machined components.

HY-180 is manufactured using advanced metallurgical techniques to ensure precision and quality:

HY-180 High Strength Alloy Steel is a versatile material used across a range of industries:

By selecting HY-180, you’re investing in:

Nickel Iron Alloy, also known as nickel–iron alloy or iron–nickel alloy, is a group of alloys primarily composed of nickel (Ni) and iron (Fe). These alloys are abbreviated as FeNi or NiFe and are significant components of planetary cores, iron meteorites, and various industrial applications. In chemistry, the acronym NiFe refers to an iron–nickel catalyst or component involved in chemical reactions. Nickel–iron alloys are crucial in geology, where they constitute the main elements of telluric planetary cores and are abundant in metallic meteorites. These alloys may be fortified with small amounts of other metals like chromium, cobalt, molybdenum, and titanium, depending on the intended use. They find applications in steel metallurgy to produce specialized steels like maraging steel and low-alloy steels, as well as in manufacturing materials like Invar and Mu-metal for specific technological purposes.

Density | Curie Temp | Melting Point | Electrical Resistivity | Thermal Conductivity | Specific Heat | Thermal Expansion |

g/cm3 | °C | °C | micro-ohm-cm | W/cm °C | Cal/g-°C | ppm/°C (25°C to 450°C) |

8.17 | 450 | 1427 | 49 | 0.13 | 0.12 | 9 |

Chemical Compositions

Weight% | C | Mn | Si | P | S | Ni | Fe |

Nickel Iron 4750 | 0.035 max | 0.8 max | 0.5 max | 0.02 max | 0.008 max | 47.0-50.0 | Bal. |

Mechanical Properties

Material | Condition | Tensile Strength | Yield Strength | Elongation (%) | Reduction of area (%) | Hardness Rb | ||

ksi | Mpa | ksi | Mpa | |||||

Alloy 4750 | As cold drawn | 95 | 655 | 80 | 552 | 25 | 62 | 98 |

Alloy 4750 | Hydrogen (2150°F) | 70 | 483 | 22 | 152 | 45 | 68 | 62 |

Alloy 4750 | Hydrogen (1600°F) | 75 | 517 | 23 | 154 | 43 | 65 | 75 |

Nickel Iron Alloys are renowned for their exceptional magnetic properties, making them invaluable in numerous industrial applications:

Our Nickel Iron Alloys are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.