Menu

MetalsTek Engineering’s Lead Evaporation Materials are renowned for their exceptional purity and consistency, making them the preferred choice for industry professionals.

Material: Lead

Purity: 99.9% ~ 99.999%

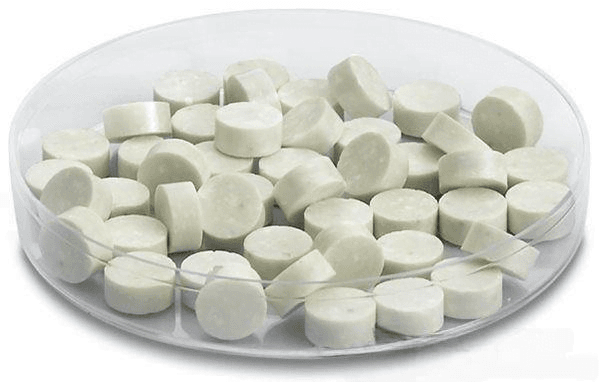

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Lead Oxide

Purity: 99.9% ~ 99.99%

Properties: 9.53g/cc Density, ≈888°C M.P.

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Lead Sulfide

Purity: 99.9% ~ 99.999%

Properties: 7.6g/cc Density, ≈1,118°C M.P.

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Lead Telluride

Purity: 99.9% ~ 99.999%

Properties: 6.14g/cc Density, ≈924°C M.P.

Form: Pellets, Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Lead Selenide

Purity: 99.9% ~ 99.999%

Properties: 8.1g/cc Density, 1,078°C M.P.

Form: Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Lead Titanate

Purity: 99.9%

Properties: 7.3g/cc Density, 1,540°C M.P.

Form: Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Lead Zirconate

Purity: 99.9%

Properties: 7.2g/cc Density, 1,390°C M.P.

Form: Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Material: Lead Zirconium Titanate

Purity: 99.9%

Properties: 7.5g/cc Density, ≈1,250°C M.P.

Form: Pieces, Powder, Customized Shapes

Size: 1~6mm, or Tailored Size

Lead Evaporation Materials are essential components used in various deposition processes, including semiconductor deposition, chemical vapor deposition (CVD), and physical vapor deposition (PVD). These materials are crucial for optics applications such as wear protection, decorative coatings, and displays. Lead Evaporation Materials are available in different forms like pellets, pieces, and wires, offering high purity levels and precise dimensions to ensure quality film deposition. They play a significant role in scientific research and industrial production processes, providing a competitive price point for their applications. These materials are carefully packaged to maintain their integrity during storage and transportation, ensuring their stability and usability in thermal evaporation and deposition processes.

Material Type | Lead | E-Beam | Excellent |

Symbol | Pb | Thermal Evaporation Techniques | Boat: W, Mo |

Atomic Weight | 207.2 | Coil: W | |

Atomic Number | 82 | Basket: W, Ta | |

Appearance | Bluish White, Metallic | Crucible: Al2O3, Q | |

Thermal Conductivity | 35 W/m.K | E-Beam Crucible Liner Material | FABMATE® |

Melting Point | 328°C | Temp. (°C) for Given Vap. Press. (Torr) | 10-8: 342 |

Coefficient of Thermal Expansion | 28.9 x 10-6/K | 10-6: 427 | |

Theoretical Density | 11.34g/cc | 10-4: 497 | |

Z Ratio | 1.13 | Suggested QCM Crystal | Gold Crystal |

Lead Evaporation Materials find applications across several industries due to their unique properties and the versatility of thin film deposition techniques. Here are some typical applications:

Lead Evaporation Materials play a vital role in various industries, enabling the creation of functional coatings, devices, and structures with tailored properties and performance characteristics.

Our Lead Evaporation Materials clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.