Menu

At MetalsTek, we are experts in manufacturing top-notch Magnesium Alloys. Our Magnesium Alloys are known for their exceptional strength-to-weight ratios, making them extremely valuable in industries where reducing weight is crucial while still maintaining or improving mechanical strength.

Material: Magnesium Zirconium Master Alloys

Composition: Mg-25Zr, Mg-30Zr, Customized

Purity: 99.9% or Customized

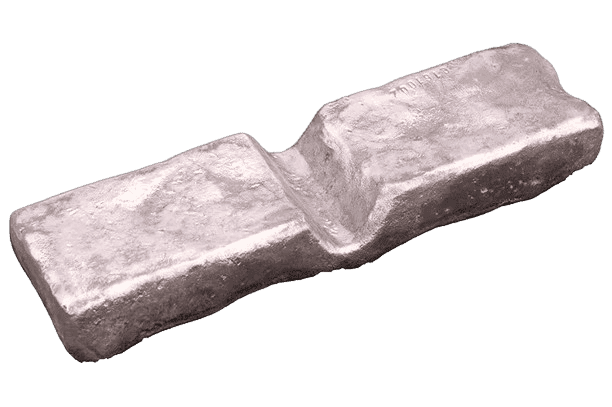

Shape: Ingot, Rod, or Customized Shape

Grade | Purity (%) | Content of Mg (%) |

MgZr-40-1 | 99.9 | 25±2 |

MgZr-40-2 | 99.9 | 30±2 |

MgZr-40-3 | 99.9 | 40±2 |

MgZr-40-C | 99.9 | Customized |

High Strength Magnesium Alloy

Tensile Strength Rm | Yield Strength Rp0.2 | Elongation A5 | Vickers Hardness |

280 – 290 Mpa | 140 – 295 Mpa | 6 – 10% | 67 – 63 |

Material: Magnesium Nickel Master Alloys

Composition: 5Mg-95Ni / 15Mg-85Ni / Mg (5%~30%) Ni, or Customized

Purity: 99.9% or Customized

Shape: Ingots

-Used as a nodulizer. The main role is to change the state of the graphite and increase the hardness of the rolls.

-Used as a negative electrode material for nickel-metal hydride batteries.

– Additives for ductile iron that enable the efficient addition of Mg to the molten iron.

– Turbocharger shell.

– Internal combustion engine exhaust pipe

Material: Magnesium Antimony Alloy

Purity: >99.5% or Customized

Properties: 3.99~4.08 g/cc Density, 961 ℃ Melting Point

Shape: Powder, 100 ~ 325 Mesh Size

The applications of Magnesium Antimony Alloy Powder (Mg/Sb) are numerous.

1. It is used in battery manufacturing, specifically as a cathode material for lithium-ion and lead-acid batteries.

2. It is also used in the semiconductor industry for thermoelectric and magnetic materials.

3. In the aerospace industry, it is used in lightweight structural components.

4. In the automotive industry, it is used for lightweight parts to improve fuel efficiency.

5. It is also used for corrosion-resistant coatings. The low density and high conductivity of this alloy make it a valuable material for many different industries.

Material: Magnesium Calcium Mg-Ca

Composition: Ca 10% ~ 25%

Purity: >99% or Customized

Shape: Ingot, Granules, Waffle

Applications: Construction, Sports & Leisure, Transportation, Household Appliances, etc.

Product Model | Mg | Ca | Impurity Content (≤%) | ||||

Fe | Si | Cu | AL | Ni | |||

Mg-Ca10 | Balance | 10±2% | 0.35 | 0.15 | 0.1 | 0.05 | 0.01 |

Mg-Ca15 | Balance | 15±2% | 0.35 | 0.15 | 0.1 | 0.05 | 0.01 |

Model: MgLi, MgSi, MgSr, MgSm, MgEr, MgYb, MgMn

Compositions: Can be Customized

Shapes: Per Requests

Sizes: Tailored Sizes

MOQ: No Minimal Order Quantity

Magnesium alloys are a class of light but strong metals that are primarily made from magnesium combined with other elements such as aluminum, zinc, and rare earth metals. They are celebrated for their excellent strength-to-weight ratios, which make them particularly valuable in industries where reducing weight is crucial while maintaining or enhancing mechanical strength.