Menu

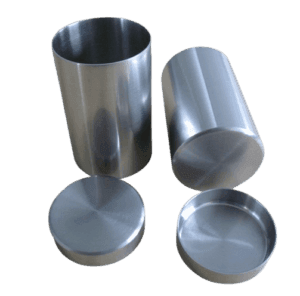

MetalsTek Engineering is a top-tier supplier of Nickel Crucibles, which are known for their exceptional quality and competitive pricing.

Material: Nickel, Ni 99.6%

Working Temperature: Up to 800°C / 1,472°F

Capacity: 5mL~500mL, or Customized

Surface: Polished

Below is our regular product list. We can also customize various shapes according to your requirements or drawings. Contact our experts for further information.

| Product Code | Capacity | Top Dia. | Bottom Dia. | Height | Thickness |

| (mL) | (mm) | (mm) | (mm) | (mm) | |

| NiC101 | 5 | 21 | 21 | 19 | 0.94 |

| NiC102 | 15 | 36 | 32 | 23 | 0.94 |

| NiC103 | 25 | 40 | 47 | 23 | 0.94 |

| NiC103A | 30 | 41 | 21 | 35 | 0.85 |

| NiC104 | 35 | 40 | 47 | 30 | 0.94 |

| NiC104A | 50 | 47 | 25 | 40 | 0.85 |

| NiC105 | 55 | 40 | 47 | 42 | 0.94 |

| NiC106 | 75 | 51 | 44 | 42 | 0.94 |

| NiC107 | 100 | 59 | 53 | 46 | 0.94 |

| NiC108 | 250 | 83 | 72 | 60 | 0.94 |

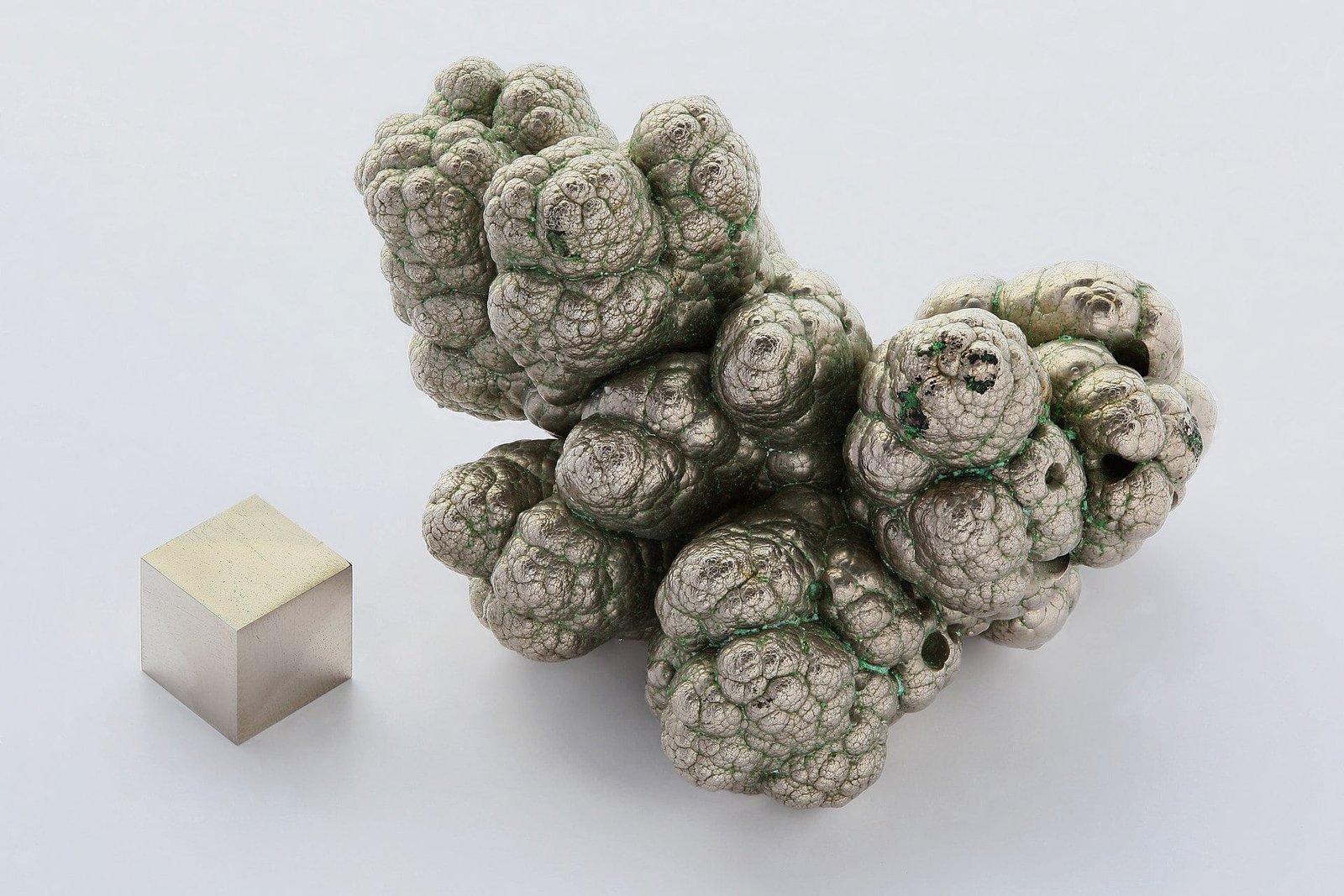

Nickel crucibles stand as essential tools in high-temperature applications, renowned for their durability, thermal stability, and resistance to corrosion. Our Nickel Crucibles are made from 99.5% pure nickel, making them highly resistant to strong alkalis and phosphoric acid. They are designed to withstand harsh use with their thicker bases and lighter walls. However, it’s worth noting that Nickel Crucibles are not the best choice for acid and sulfur compound solvents.

Nickel Crucibles find applications in diverse fields, including metallurgy, chemical processing, materials research, and laboratory settings. Their ability to withstand harsh conditions while maintaining dimensional stability and purity makes them indispensable for tasks such as melting and casting metals, performing high-temperature reactions, and conducting experiments in controlled environments.

Nickel Crucibles find applications across a range of industries and scientific fields due to their unique properties and ability to withstand high temperatures and corrosive environments. Here are some common applications:

These diverse applications highlight the versatility and importance of Nickel Crucibles in various industrial, scientific, and research endeavors.

Our Nickel Crucibles are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.

Nickel crucibles are essential tools in various high-temperature applications, commonly used for melting, heating, or holding materials under extreme conditions. Whether you’re involved in metal casting, laboratory experiments, or industrial applications, a nickel crucible offers durability and resistance to corrosive environments. In this guide, we will explore the properties, applications, working temperatures, and maintenance tips, including cleaning methods, to ensure your crucible performs optimally.

A nickel crucible is a small container made from high-purity nickel metal, designed to withstand high temperatures without corroding or degrading. These crucibles are typically used for applications involving molten metals, ceramics, or chemicals that require a stable, high-temperature environment. Nickel is chosen for crucibles due to its excellent resistance to corrosion, even in challenging environments such as those involving acids or alkalis.

Nickel Crucible with Lid: Some nickel crucibles come with a matching lid to reduce contamination from the surrounding atmosphere and maintain temperature consistency. The lid helps prevent the oxidation of certain materials, making it especially useful when dealing with reactive metals or alloys.

Nickel crucibles possess several key properties that make them highly valued in industrial and laboratory settings:

High Melting Point: Nickel has a melting point of 1455°C (2651°F), which makes it suitable for high-temperature applications where other metals may fail.

Corrosion Resistance: Nickel is highly resistant to corrosion, particularly in dilute alkali solutions. This makes nickel crucibles ideal for use in environments where chemical resistance is crucial, such as molten metal processing or chemical reactions.

Strength and Durability: Nickel maintains its strength and mechanical properties even at high temperatures, ensuring that crucibles can withstand repeated heating cycles without cracking or warping.

Thermal Conductivity: Nickel has good thermal conductivity, which helps to distribute heat evenly across the crucible, ensuring consistent temperatures.

Non-reactivity: Nickel’s resistance to oxidation and other chemical reactions means that it won’t interact with the contents inside the crucible, making it a reliable choice for a wide range of chemical processes.

Nickel crucibles can endure temperatures up to around 1200°C (2192°F) in a non-oxidizing atmosphere. However, the exact working temperature depends on the specific alloy and design of the crucible. Nickel-based alloys like nickel-chromium (NiCr) or nickel-molybdenum (NiMo) alloys are often used for crucibles to improve their heat resistance and longevity in extreme conditions.

If you plan to use the crucible for temperatures exceeding this range, it’s advisable to consider a nickel alloy crucible for added heat resistance. If the crucible will be exposed to oxidative conditions (e.g., air), temperatures beyond 1000°C can start to degrade the material, leading to oxide formation on the surface.

Nickel crucibles are versatile and have many applications across industries, including:

Metallurgy: Used for melting or holding metals at high temperatures, such as gold, silver, and platinum. The high melting point of nickel allows it to endure these extreme conditions.

Casting: In jewelry making, aerospace, and automotive industries, nickel crucibles are used to melt metals for casting.

Chemical Analysis: Nickel crucibles are used in laboratories for chemical reactions that involve high temperatures, such as fusion or igniting substances.

Research and Development: R&D facilities use nickel crucibles to perform experiments involving molten materials or high-temperature reactions, such as testing new alloys or compounds.

Heat Treatment: Nickel crucibles are also used in heat treatment processes for industrial parts, especially those that need to be heated without undergoing significant chemical reactions.

Nickel crucibles are a popular choice for various high-temperature applications due to their unique properties and advantages. Below are some key benefits of using nickel crucibles in industrial, laboratory, and metalworking settings:

Nickel has a high melting point of approximately 1455°C (2651°F), making it ideal for handling extreme temperatures. Nickel crucibles can endure intense heat without degrading, which makes them particularly useful in metal melting, casting, and other high-temperature processes.

Nickel’s inherent resistance to corrosion is one of its most significant advantages. It resists oxidation in high-temperature environments and is particularly resistant to dilute alkalis and some acids. This makes nickel crucibles ideal for use in chemical analysis, molten metal applications, or environments where the crucible may come into contact with reactive chemicals.

Nickel crucibles are known for their durability and can withstand repeated heating cycles without warping or cracking. The material’s mechanical strength remains stable even at high temperatures, ensuring that your crucible lasts longer than those made from less heat-resistant materials.

Nickel does not react with most molten metals, making it an excellent choice for casting and metal processing. This is critical when dealing with sensitive materials like gold, platinum, or other reactive metals, as it prevents contamination and maintains the purity of the metal being worked on.

Nickel offers good thermal conductivity, which means that it distributes heat evenly across the crucible’s surface. This helps achieve uniform heating of materials inside the crucible, ensuring consistent results, especially in applications like metal melting, soldering, and chemical reactions.

While nickel is generally more expensive than other materials, its long-term durability and resistance to corrosion make it a cost-effective solution for industries where high-performance and longevity are paramount. With proper care and maintenance, a nickel crucible can last much longer than cheaper alternatives.

Nickel’s smooth surface makes it relatively easy to clean. While some metals can accumulate stubborn residues or become contaminated over time, nickel’s resistance to oxidation means that it is less likely to develop unwanted buildup. Cleaning a nickel crucible is simple, usually requiring just a mild acid wash to remove any contaminants.

Nickel crucibles are used across a wide range of industries, including metallurgy, aerospace, chemistry, and research. They are suitable for use in high-temperature casting, heat treatment, and chemical reactions, as well as in specialized fields like solar energy research or semiconductor manufacturing.

Nickel crucibles can be used to melt and handle high-temperature alloys, including titanium, platinum, and aluminum, without significant degradation. This makes them invaluable in industries where specific alloy combinations are needed for advanced applications like aerospace or electronics.

Nickel crucibles are highly resistant to a variety of reactive elements, which means they can be used in processes that involve highly reactive metals or chemicals. This resistance is particularly useful when working with materials such as magnesium, zinc, or lithium, which can otherwise cause corrosion in less durable crucible materials.

Nickel crucibles are highly resistant to dilute alkalis, including sodium hydroxide (NaOH) and potassium hydroxide (KOH). This property makes them ideal for chemical processes involving bases, which would normally corrode other materials like aluminum or iron.

However, it’s important to note that while nickel is resistant to dilute alkalis, it can be more vulnerable to concentrated alkalis and prolonged exposure to high temperatures. It’s essential to carefully monitor the crucible’s condition and avoid any chemical interactions that could lead to damage.

Proper cleaning of a nickel crucible ensures that it maintains its performance and longevity. Here’s how to clean it:

Cool Down: Allow the crucible to cool down completely after use. Never clean a hot crucible, as the sudden temperature change could crack or warp it.

Remove Debris: Use a soft brush or cloth to remove any large particles or debris from the surface. Avoid using abrasive tools that could scratch the surface of the crucible.

Use Chemical Cleaners: For more stubborn residues, especially after high-temperature applications, you can use a mild acid solution like diluted hydrochloric acid to dissolve any built-up oxides or metal deposits. Always wear protective gloves and safety glasses when handling chemicals.

Rinse Thoroughly: After cleaning, rinse the crucible with water and dry it completely to prevent corrosion. Ensure that no cleaning residue is left behind.

Polishing: If the crucible has tarnished or accumulated a layer of oxidation, use a nickel polishing solution or a fine abrasive cloth to restore the shine. This step is optional but can enhance the crucible’s appearance.

Storage: Store the crucible in a dry, cool place when not in use to prevent corrosion. If exposed to air, it’s advisable to coat it lightly with an anti-corrosive layer or keep it in a sealed container.

Nickel crucibles are indispensable tools in high-temperature industries, thanks to their unique combination of heat resistance, durability, and chemical inertness. They are used in a variety of applications, from metallurgy and casting to laboratory experiments and chemical analysis. Proper care and cleaning are essential to prolong the crucible’s lifespan, ensuring it continues to perform at its best for years. Whether you’re a manufacturer, researcher, or enthusiast, investing in high-quality nickel crucibles ensures that your processes remain efficient, cost-effective, and safe.

At MetalsTek, we take great pride in providing top-notch Nickel Crucibles that meet the demanding requirements of today’s industries. Our dedication to quality, coupled with our capability to tailor targets to precise sizes and compositions, positions us as the go-to choice for businesses looking to push boundaries and achieve greatness.