Menu

MetalsTek Engineering is a professional manufacturer and supplier of Nickel Mesh, Nickel Electrodes, Nickel and Nickel Alloy Foams, and Filters. We can provide Nickel and Nickel alloy foams and meshes with short lead times and good prices.

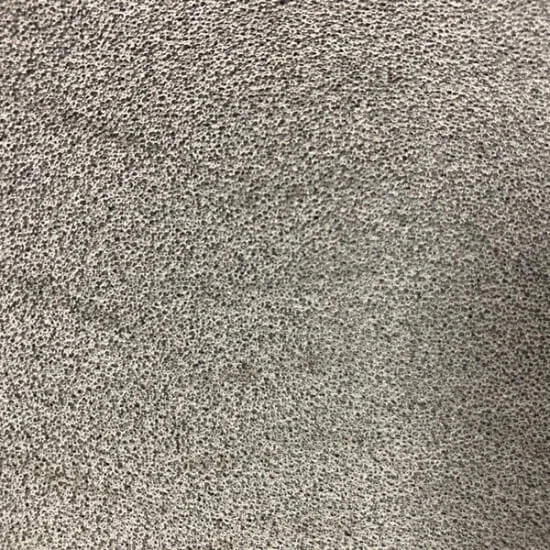

Material: Nickel

Purity: Ni>95%, Ni+Co>99.8%

Form: Sheet, Plate, Belt, or Customized

Size: Thk. 0.3~100mm, Width 10~500mm, Length 10~1500mm

Nickel foam serves as an excellent carrier material for exhaust gas purifiers, battery electrode materials, and various catalyst carriers. It is especially suitable for filter materials requiring high-temperature resistance and resistance to acid and alkali corrosion. Additionally, it is used as a surface layer material for infrared burners and as a heating material in various industrial and civil drying equipment.

Chemical Power Supply In chemical power supply applications, nickel foam is utilized in nickel-hydrogen, nickel-cadmium, and fuel cells as positive and negative electrodes, significantly enhancing battery performance. The foamed nickel-carbon composite electrode material is ideal for lithium batteries.

Chemical Engineering In chemical engineering, nickel foam acts as a catalyst and catalyst carrier, a filter medium, and a medium in separators (such as water separators, automobile exhaust gas purifiers, and air purifiers). Its large specific surface area helps reduce energy consumption and improve efficiency.

Electrochemical Engineering In electrochemical engineering, nickel foam is used to enhance hydrogen production efficiency, electrocatalytic processes, and electrochemical metallurgy, significantly boosting energy efficiency.

Thermal Engineering In thermal engineering, nickel foam functions as a damping material and a high-efficiency heat-conducting “wick” material for “heat pipes,” doubling their efficiency.

Functional Materials As a functional material, nickel foam can absorb wave energy, provide silencing, vibration absorption, buffer electromagnetic shielding, and enhance stealth technology. It also offers flame retardant and thermal insulation properties.

Additional Uses Nickel foam is also used as rectification tower packing, condenser heat exchange material, chemical catalyst carrier material, power battery electrode material, industrial filter material, high-grade decorative material, and industrial filter.

Material: Nickel-Chromium

Porosity: 95%~98%

Melting Point: 1,400 ℃

Form: Sheet, Plate, Belt, or Customized

Size: Thk. 1~50mm, Width 10~500mm, Length 10~1500mm

Pore Size: 0.3~7 mm (10~140ppi)

* Fuel cell electrode materials

* Chemical engineering field:

Catalyst and its carrier, filter medium, medium in the separator (such as oil-water separator, automobile exhaust gas purifier, air purifier, etc.), rectification tower packing, heat exchange material

* Electrochemical Engineering:

Electrolytic hydrogen production, electrocatalytic process, electrochemical metallurgy

* Thermal engineering:

Damping material, the high-efficiency thermal conductive material

* Functional materials area:

Buffer electromagnetic shielding, stealth technology, flame retardant, thermal insulation

* Industrial field:

Industrial filter materials, high-grade decorative materials, industrial filters

Material: Nickel Iron Alloy, Composition Customized

Porosity: 60%~98%

Form: Sheet, Plate, Belt, or Customized

Size: Thk. 0.3~30mm, Width 600mm, Length 600mm

PPI: 5~130ppi

Iron-nickel Foam, also known as Fe-Ni foam, is a porous material made from a combination of iron (Fe) and nickel (Ni) metals. It is characterized by its open-cell, sponge-like structure, which consists of interconnected metal struts and void spaces. This foam material is known for its unique properties and finds applications in various industries. It features ultra-light quality, good sound absorption, electron wave shielding, processability, fire resistance as well and strong thermal conductivity.

Features:

Ultra-light quality: It has the largest specific surface area, a specific gravity is 0.2~0.3, which is 1/4 of water, 1/3 of wood, 1/10 of metal aluminum, 1/30 of iron, and ultra-light quality.

Sound absorption: The porous structure has a wide frequency of sound absorption.

Electron wave shielding: Shields electron waves of around 90 dB through a relatively thin thickness.

Processability: Can be cut, bent, and simply pasted.

Fire resistance: It maintains a stable shape and is difficult to burn at high temperatures and is resistant to high temperatures.

Recycling: Metal waste materials can be recycled 100%.

Thermal conductivity: Porous materials have strong thermal conductivity.

Breathable: a homogeneous three-dimensional network structure with filtering effect and the flow stability of gas and fluid is super strong.

Sound insulation: Through additional processing, a high noise interception can be obtained, and the sound insulation effect is good.

Material: Nickel Copper Alloy, Composition Customized

Porosity: 50%~98%

Form: Sheet, Plate, Belt, or Customized

Size: Thk. 1~50mm, Width 600mm, Length 600mm

PPI: 5~150ppi

Material: Nickel Copper Alloy, Composition Customized

PUrity: >99%

Porosity: >95%

Form: Sheet, Plate, Belt, or Customized

Size: Thk. 1~5mm, Width 10~1,000mm

PPI: 50~150ppi

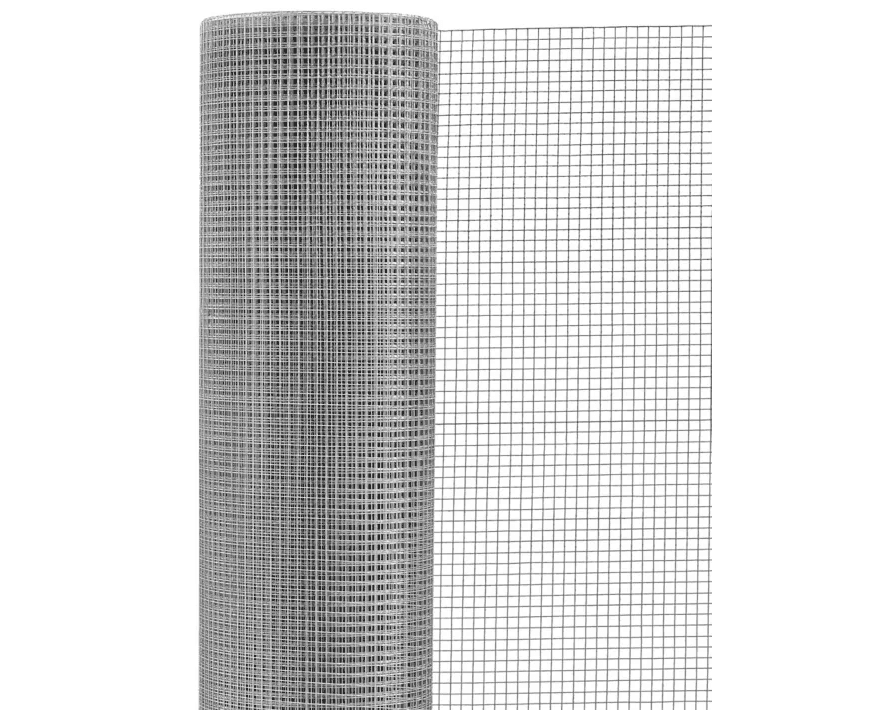

Material: Nickel

Wire Diameter: 0.027mm~0.5mm

Mesh Size: 4~400 Mesh

Form: Crossing the Nickel Warp Weft, Square/Rectangular Mesh

Width: 10~1,000mm

Mesh | Diameter Of Mesh (mm) | Aperture (mm) |

10 | 0.5 | 2.04 |

20 | 0.3 | 0.97 |

30 | 0.2 | 0.64 |

40 | 0.15 | 0.485 |

50 | 0.15 | 0.358 |

60 | 0.12 | 0.3 |

80 | 0.1 | 0.2 |

100 | 0.1 | 0.154 |

120 | 0.08 | 0.11 |

150 | 0.06 | 0.1 |

180 | 0.06 | 0.08 |

200 | 0.05 | 0.07 |

250 | 0.04 | 0.06 |

300 | 0.032 | 0.05 |

350 | 0.03 | 0.04 |

400 | 0.027 | 0.036 |

Material: Nickel, N2, N4, N6

Size: 500*1000mm, 600*1200mm, 1000*1000mm, 1200*1200mm

Thickness: 0.5~0.8mm

Features: Good Mechanical Strength, Thermal Corrosion Resistance, etc.

-Hydraulic oils filtration

-Polymer industry

-Storage silos

-Food Processing

-Driers & Coolers

-Chemical products filtration

-Fluidization of bulk materials in gravity conveyors

-Pharmaceuticals and cosmetic

-Fuel processing, etc.

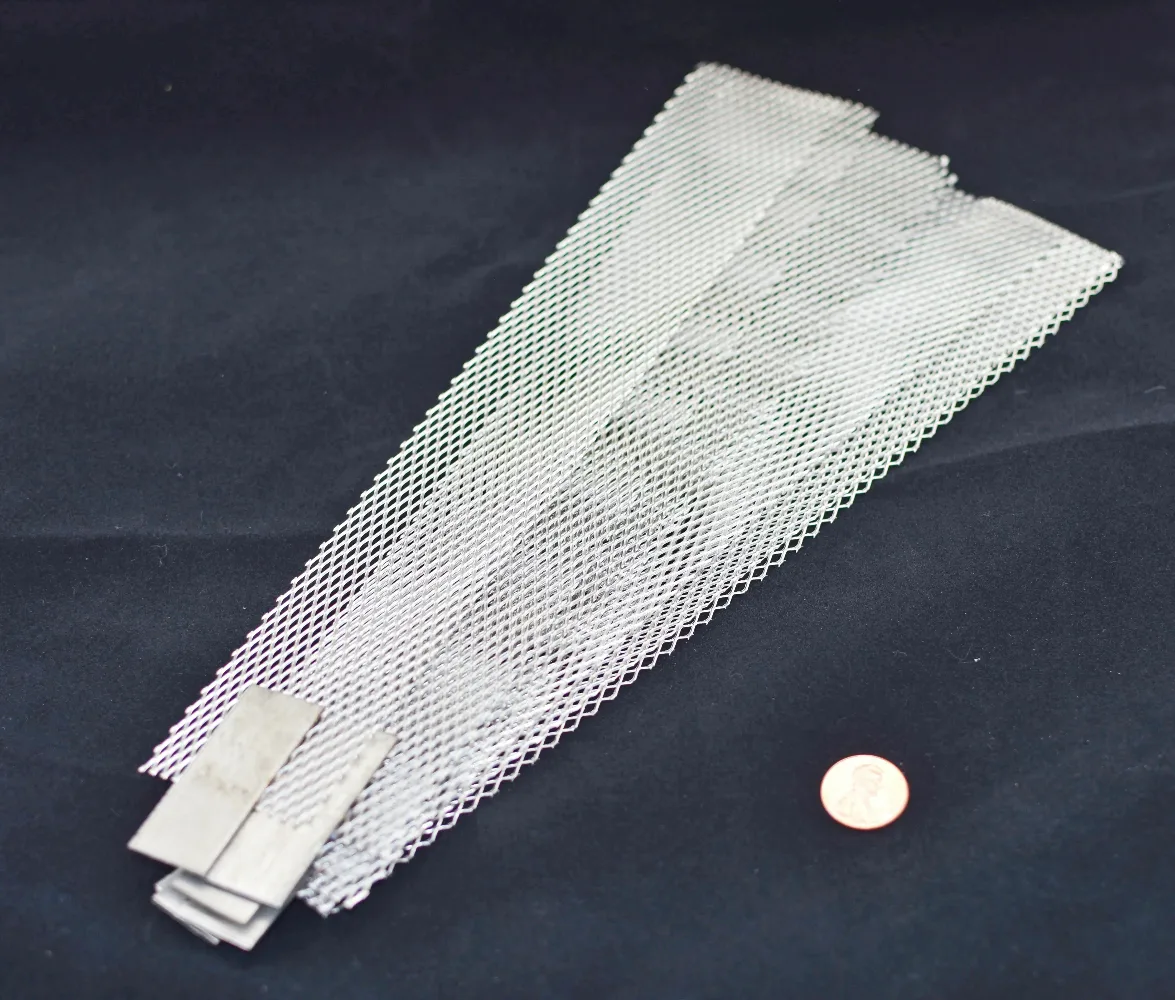

Material: Nickel, N4 (Ni201), N6 (Ni200)

Current: <8000 A/m2

Form: Mesh, Wire, Plate, Sheet

MOQ: 2m2

Applications: Electrochemical Engineering, Chemical Powder Supply, Functional Materials

| Range No. | SWD(mm) | LWD(mm) | Strand Thickness(mm) | Strand Width(mm) | Sheet Width(mm) | MOQ |

|---|---|---|---|---|---|---|

| 1 | 0.3 | 0.5 | 0.08-0.10 | 0.10-0.15 | 70-100 | 2 ㎡ |

| 2 | 0.5 | 0.7 | 0.08-0.10 | 0.10-0.15 | 70-100 | 2 ㎡ |

| 3 | 0.6 | 0.8 | 0.08-0.10 | 0.15-0.20 | 100-200 | 2 ㎡ |

| 4 | 0.7 | 1 | 0.10-0.15 | 0.15-0.20 | 100-200 | 2 ㎡ |

| 5 | 0.7 | 1.25 | 0.10-0.20 | 0.15-0.25 | 100-250 | 2 ㎡ |

| 6 | 0.9 | 1.5 | 0.10-0.30 | 0.20-.30 | 100-300 | 2 ㎡ |

| 7 | 0.9 | 1.5 | 0.20-0.40 | 0.20-0.40 | 100-300 | 2 ㎡ |

| 8 | 1 | 2 | 0.15-0.40 | 0.15-0.5 | 150-300 | 2 ㎡ |

| 9 | 1.4 | 2 | 0.15-0.50 | 0.15-0.50 | 150-500 | 2 ㎡ |

| 10 | 1.5 | 2.5 | 0.20-0.50 | 0.20-0.50 | 150-500 | 2 ㎡ |

| 11 | 2 | 3 | 0.20-0.60 | 0.20-0.60 | 150-600 | 2 ㎡ |

| 12 | 2.2 | 3 | 0.20-0.60 | 0.20-0.60 | 150-600 | 2 ㎡ |

| 13 | 2.4 | 3 | 0.20-0.60 | 0.20-0.60 | 150-600 | 2 ㎡ |

| 14 | 2.4 | 3.5 | 0.20-0.60 | 0.20-0.60 | 150-600 | 2 ㎡ |

| 15 | 2.4 | 4 | 0.20-0.60 | 0.20-0.60 | 150-600 | 2 ㎡ |

| 16 | 3 | 5 | 0.20-0.60 | 0.20-0.60 | 150-600 | 2 ㎡ |

| 17 | 3 | 6 | 0.20-0.60 | 0.20-0.60 | 150-600 | 2 ㎡ |

| 18 | 4 | 6 | 0.20-0.60 | 0.20-0.60 | 150-600 | 2 ㎡ |

| 19 | 4 | 8 | 0.20-0.60 | 0.20-0.60 | 150-600 | 2 ㎡ |

| 20 | 5 | 10 | 0.20-0.60 | 0.20-0.60 | 150-600 | 2 ㎡ |

| 21 | 7 | 12.5 | 0.20-0.60 | 0.20-0.60 | 150-600 | 2 ㎡ |

| 22 | 8 | 16 | 0.20-0.60 | 0.20-0.60 | 150-600 | 2 ㎡ |

| 23 | 10 | 20 | 0.20-0.60 | 020-0.60 | 150-600 | 2 ㎡ |

Material: Cr20Ni80, Cr15Ni60 and Cr20Ni35

Wire Diameter: 0.03mm~1.6mm / 0.0014″–0.063″

Mesh Size: 4~325 Mesh

Material | Chemical Composition (%) | Max. Working Temp. (℃) | |||||

C | Si | Mn | Ni | Cr | Mo | ||

Cr20Ni80 | 0.15 | 0.4-1.3 | 0.7 | 75-78 | 20-23 | – | 1200 |

Nickel mesh is a versatile and durable material made from high-purity nickel wire woven into a grid pattern. It is widely used in applications requiring excellent conductivity, corrosion resistance, and mechanical strength, such as filtration, battery components, and chemical processing.

Nickel foam is a lightweight, highly porous material with a three-dimensional open-cell structure. It provides a large surface area, making it ideal for applications in energy storage, such as battery electrodes, fuel cells, and supercapacitors. Its excellent electrical conductivity and thermal properties enhance performance and efficiency in these devices.

Nickel mesh electrodes are high-performance electrodes made from woven nickel mesh. They offer superior conductivity, corrosion resistance, and mechanical strength, making them ideal for use in electrochemical applications such as batteries, fuel cells, and electrolysis processes. These electrodes ensure efficient and reliable operation in various energy storage and conversion systems.

Our Nickel Foam, Mesh and Mesh Electrodes are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.