Menu

MetalsTek Engineering is a worldwide leading supplier of Nickel Wire and Rod.

Material: Nickel, Ni

Purity: 99.9%, 99.95%

Form: Wire, Flat Wire, Rod, Bar, Square Bar, or Customized

Size: Diameter 0.025mm ~ 4mm * Length, Can be Customized

Material: Nickel, Ni

Purity: 99.9%

Form: Wire, Flat Wire, Rod, Bar, Square Bar, or Customized

Size: Diameter 2mm ~ 60mm * Length, Can be Customized

Material: Nickel Alloy N6

Properties: 8.89g/cc, 1,430~1,450℃ M.P.

Form: Wire, Rod, Bar, or Customized

Size: Diameter 6~35μm (6/8/12/20/25/35μm)

Standard: Q/XY2003-2002

Applications: Germproof Fabric (Ni fiber); Buttery

Material: Nickel Ni200

Grade: UNS N02200

Properties: 8.89g/cc Density, 1440 ℃ M.P.

Form: Wire, Rod, Bar, or Customized

Size: Tailored Size

Material: Monel 405 Alloy, UNS N04405

Standard: ASTM B164, ASME SB-164, AMS 4674

Properties: 8.8g/cc Density, 1,300~1,350 ℃ M.P.

Form: Form: Wire, Rod, Bar, or Customized

Chemical Compositions (%)

Ni | Cr | Mo | Co | Ti | Al | Fe | C | Mn | S | Si | B |

Bal. | 18.0-20.0 | 9.0-10.5 | 10.0-12.0 | 3.0-3.3 | 1.4-1.6 | 5.0 max | 0.05-0.12 | 0.10 Max | 0.015 max | 0.50 max | 0.003-0.010 |

Mechanical Properties

Condition | Tensile | .2% Yield | Elongation | Hardness Brinell | Hardness |

(ksi) | (ksi) | % | (3000 kg) | Rockwell B | |

Annealed | 70-85 | 25-40 | 50-35 | 110-140 | 60-76 |

Hot-Finished | 75-90 | 35-60 | 45-30 | 130-170 | 72-86 |

Cold-Drawn As-Drawn | 85-115 | 50-105 | 35-15 | 160-245 | 85-23C |

Material: Incoloy A286 Alloy

Standard: ASTM A286, SAE AMS 5525, 5858

Properties: 7.92g/cc Density, 1,370~1,430 ℃ M.P.

Form: Form: Wire, Rod, Bar, or Customized

Fe | Ni | Cr | Ti | Al | C |

Bal. | 24-27 | 13.5-16 | 1.90-2.30 | ≤0.35 | ≤0.08 |

Mn | Si | Mo | V | B |

|

≤2.0 | ≤1.0 | 1.00-1.75 | 0.10-0.50 | 0.003-0.010 |

Material: Inconel C-276 Alloy

Standard: UNS N10276; ASTM B574, B575, B619, B626, B622

Properties: 8.29g/cc Density, <900 ℃ M.P.

Form: Form: Wire, Rod, Bar, or Customized

Nickel | Molybdenum | Chromium | Iron | Tungsten | Cobalt |

Remainder | 15.0-17.0 | 4.5-16.5 | 4.0-7.0 | 3.5-4.5 | 2.5 max |

Manganese | Vanadium | Silicon | Phosphorus | Sulfur | Carbon |

1.0 max | 0.35 max | 0.08 max | 0.04 max | 0.03 max | 0.010 max |

Material: Hastelloy X Alloy, Ni Cr Fe Mo

Standard: ASTM B619, B622

Form: Form: Wire, Rod, Bar, or Customized

C | Cr | Ni | Co | W | S | P |

0.05-0.15 | 20.5-23.0 | Bal. | 0.5-2.5 | 0.2-1.0 | ≤0.015 | ≤0.025 |

Mo | Fe | Mn | Si | Cu | B | Ti |

8.0-10.0 | 17-20 | ≤1.0 | ≤1.0 | 0.5 | 0.01 | ≤0.015 |

Material: Co30Ni35Cr20Mo12

Standard: UNS R300035, AMS 5758, 5844, 5845, ASTM F-562

Form: Form: Wire, Rod, Bar, or Customized

Chemical Compositions

Element | Wt% | Element | Wt% |

Cobalt | 30.0 min. | Chromium | 19.0-21.0 |

Nickel | 33.0-37.0 | Molybdenum | 9.0-15 |

Titanium | 1 | Iron | 1 |

Carbon | 0.025 | Manganese | 0.15 |

Phosphorous | 0.015 | Sulfur | 0.01 |

Silicon | 0.15 |

|

|

Maximum % unless a range is indicated | |||

Melting Range | 2400-2625°F | 1315-1440°C |

Modulus of Elasticity, RT2 | 34 x 106 psi | 234 X 103 MPa |

Poisson’s Ratio | 0.4 | 0.4 |

Coefficient of Thermal Expansion | 7.4 x 10-6 /°F | 13.5 X 10-6 /°C |

Electrical Resistivity @ RT | 40.7 µΩ in. | 103.3 µΩ cm |

Thermal Conductivity | 7.77 BTU/hr-ft-°F | 13.4 W/m-K |

Density | 304 lb/in3 | 8.41 g/cm3 |

Relative Magnetic Permeability | 1.0009 μ | 1.0009µ |

Specific Heat | 0.18 BTU/lb-F | 753 J/kg-K |

Condition | Approx. Tensile Strength | Approx. Operating Temperature | ||

N/mm2 | ksi | °C | F | |

Annealed | 800-1000 | 116-1450 | -515 | -930 |

Spring Temper | 1400-1900 | 203-276 | -515 | -930 |

Spring Temper+ Aged | 1900-2200 | 276-319 | -515 | -930 |

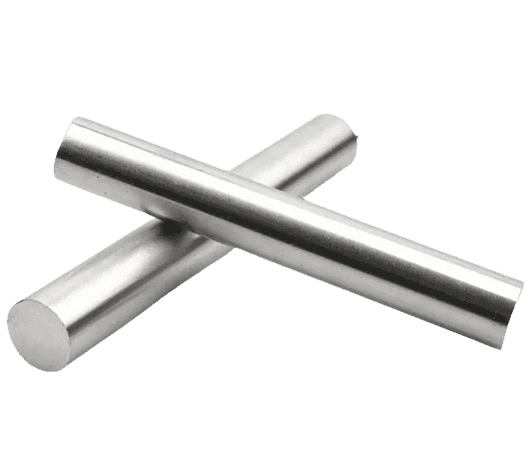

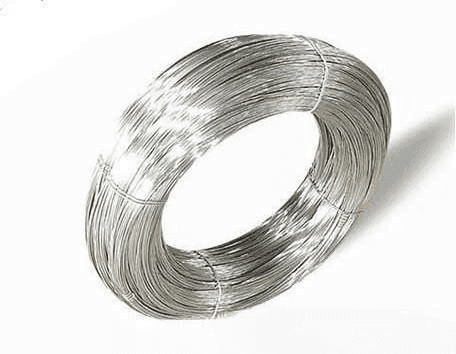

Nickel Wire and Nickel Rod are essential materials in numerous industrial applications, renowned for their exceptional properties and versatility. Nickel Wire typically refers to thin, elongated strands of nickel, prized for their high conductivity, corrosion resistance, and malleability. These qualities make Nickel Wire ideal for use in electrical wiring, heating elements, and various electronic components. Nickel Rod, on the other hand, refers to solid cylindrical bars or rods made of nickel, crafted through processes like casting or extrusion. Nickel Rods exhibit similar properties to Nickel Wire, with added strength and durability, making them suitable for applications such as welding electrodes, structural components, and machining operations. Both Nickel Wire and Rod play pivotal roles across industries such as electronics, automotive, aerospace, and manufacturing, highlighting their importance in modern engineering and technology.

Various industries rely on Nickel Wire and Rod due to their critical role in modern engineering, manufacturing, and technology. MetalsTek caters to the diverse needs of these industries, ensuring that our high-quality products remain in demand and contribute to the advancement of numerous sectors.

Our Nickel Wires Rods and Bars are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.