Menu

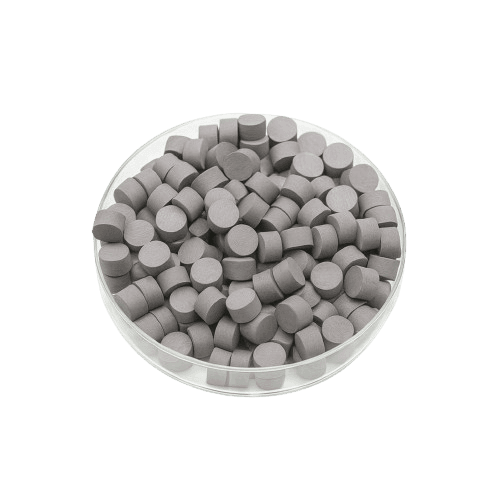

Material: Carbon (Graphite / High-Purity Carbon)

Purity: 99.9% ~ 99.999%

Form: Pellets, Granules, Rods, Chips, Powder, or Customized

Size: 2–6 mm Pellets, Rod Segments, or Customized

Applications: PVD, CVD, Optical Coatings, Semiconductor Films, DLC Coatings

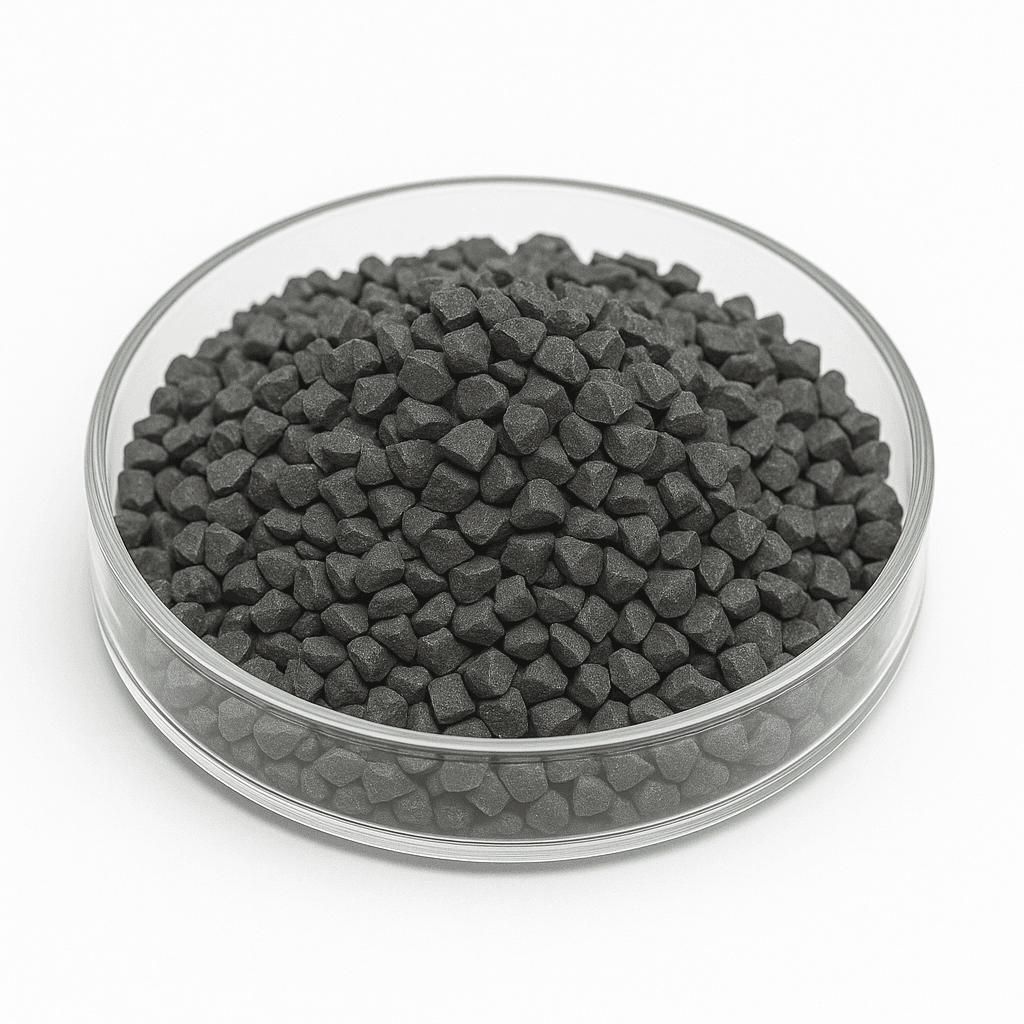

Material: Silicon Carbide

Purity: 99.9% ~ 99.999%

Properties: 3.21 g/cc Density, >2,700 °C Sublimation

Form: Granules, Pieces, Powder, or Customized

Size: 1–12 mm Pieces or Customized

Applications: Hard Coatings, Semiconductor Films, MEMS, Optical Protection Layers

Material: Boron Carbide

Purity: 99.9%

Properties: 2.52 g/cc Density, >2,400 °C Sublimation

Form: Pellets, Granules, Powder, or Customized

Size: 1–10 mm Pieces or Customized

Applications: Wear-Resistant Films, Anti-Reflective Coatings, Aerospace & Defense Coatings

Material: Tungsten Carbide

Purity: 99.9%

Properties: 15.7 g/cc Density, >2,870 °C M.P.

Form: Pellets, Granules, Powder, or Customized

Size: Tailored Sizes

Applications: Hard Protective Films, Tool Coatings, Microelectronics

Material: Titanium Carbide

Purity: 99.9%

Properties: 4.93 g/cc Density, 3,160 °C M.P.

Form: Pieces, Powder, Granules, or Customized

Size: 1–6 mm Pieces or Tailored Sizes

Applications: Conductive Films, Hard Coatings, Optical Components

Material: Zirconium Carbide

Purity: 99.9%

Properties: 6.73 g/cc Density, 3,550 °C M.P.

Form: Granules, Pieces, Powder, or Customized

Size: Tailored Sizes

Applications: Infrared Coatings, Aerospace Films, High-Temperature Optical Layers

Material: Hafnium Carbide

Purity: 99.9%

Properties: ≈12.7 g/cc Density, ≈3,900 °C M.P. (one of the highest)

Form: Pellets, Granules, Powder, or Customized

Size: Tailored Sizes

Applications: Extreme-Temperature Coatings, IR-Reflective Films, Semiconductor Hard Layers

Material: Niobium Carbide

Purity: 99.9%

Properties: 7.82 g/cc Density, 3,600 °C M.P.

Form: Pieces, Granules, Powder, or Customized

Size: 1–6 mm or Tailored Sizes

Applications: AR Coatings, Wear-Resistant Films, Advanced Electronics

Material: Chromium Carbide

Purity: 99.9%

Properties: ~6.7 g/cc Density, ~1,900 °C M.P.

Form: Pellets, Granules, Powder, or Customized

Size: Tailored Sizes

Applications: Optical Films, Corrosion-Resistant Coatings, Metallic-Carbide Layers

Material: Molybdenum Carbide

Purity: 99.9%

Properties: 9.18 g/cc Density, ~2,690 °C M.P.

Form: Pellets, Powder, Granules, Customized

Size: Tailored Sizes

Applications: Catalytic Films, Semiconductor Films, High-Hardness Coatings

| Material Type | Carbon (Graphite) |

|---|---|

| Symbol | C |

| Atomic Weight | 12.011 |

| Atomic Number | 6 |

| Appearance | Black / Dark Gray, Matte or Crystalline (Graphite) |

| Thermal Conductivity | ~120–200 W/m·K (Graphite, depending on grade) |

| Melting / Sublimation Point | Sublimes at ~3,642 °C |

| Coefficient of Thermal Expansion | ~4–8 × 10⁻⁶ /K (orientation dependent) |

| Theoretical Density | 2.0–2.26 g/cc (graphite density range) |

| Z Ratio | ~1.00 |

| E-Beam | Excellent (stable, clean evaporation) |

Carbon (C) and carbon-based evaporation materials—such as graphite, amorphous carbon, carbides (SiC, B₄C, WC, etc.)—play critical roles across advanced technology sectors due to their exceptional thermal, mechanical, electrical, and chemical properties. Below is an overview of their representative applications:

Carbon is widely used in thin film deposition for semiconductor, storage, and precision coating applications.

Carbon-based thin films—such as amorphous carbon, DLC (diamond-like carbon), and carbide layers—serve as:

Protective coatings

Hard, wear-resistant surfaces

Conductive or resistive layers

Barrier layers in semiconductor fabrication

These films are essential in microelectronics, magnetic storage media, and next-generation device architectures.

Carbon and carbide materials are important in optical engineering:

Boron carbide (B₄C) and silicon carbide (SiC) are widely used as high-absorbing coatings in EUV, X-ray, and synchrotron optics.

Carbon thin films are used as antireflective layers, beam-shaping coatings, and thermal management layers in optical assemblies.

Their excellent hardness, stability, and broad-spectrum absorption make them indispensable in high-energy optical systems.

Carbon-based evaporants—especially DLC and carbide coatings—provide outstanding protection against:

Corrosion

Abrasion

High-temperature oxidation

These coatings are used in cutting tools, dies, bearings, engine components, and harsh-environment mechanical assemblies.

Due to its high temperature resistance, low density (for carbides), and strong mechanical properties, carbon-based coatings are applied in:

Thermal barrier layers

Tribological (low-friction) coatings

EMI shielding films

Structural protection under extreme heat loads

SiC and B₄C coatings are particularly valuable in aerospace optics, propulsion systems, and high-stress components.

Carbon plays multiple roles in semiconductor device manufacturing:

Amorphous carbon is used as a hard mask material in lithography.

Carbon films provide conductive/anti-static surfaces in device packaging.

Carbides (WC, TiC, SiC) serve as diffusion barriers, gate materials, and high-κ dielectric interfaces.

Carbon evaporation materials are critical in advanced integrated circuits, memory devices, and packaging technologies.

Carbon materials are foundational in modern energy systems:

Used as electrode coatings and buffer layers

Serve as conductive additives in lithium-ion and next-generation batteries

Improve thermal stability and cycling performance

Carbides like Mo₂C and WC also act as catalytic materials in hydrogen generation and energy-conversion platforms.

Carbon-based films—especially DLC—are valued for:

Biocompatibility

Low friction

Chemical inertness

They are used in:

Medical implants

Surgical instruments

Wear-resistant biomedical components

These coatings enhance durability while maintaining compatibility with human tissue.

Boron carbide (B₄C), silicon carbide (SiC), and tungsten carbide (WC) are among the hardest engineered materials known.

Their applications include:

Armor systems

Neutron absorption materials

High-hardness wear layers

Aerospace-grade protective components

Their combination of hardness, chemical resistance, and thermal stability makes them ideal for extreme-condition engineering.

Carbon and carbides are widely used in high-temperature metallurgy:

Graphite serves as a crucible, mold, and evaporation source material

Carburizing layers improve steel hardness

Carbides act as reinforcing phases in advanced metal-matrix composites

Carbon’s heat tolerance makes it indispensable in thermal processing and vacuum metallurgy.

Carbon-based materials are widely used as:

Catalyst supports

Reactive surfaces

High-temperature reaction media

Carbides such as Mo₂C and WC exhibit catalytic activity in hydrogenation, reforming, and electrochemical reactions.