Menu

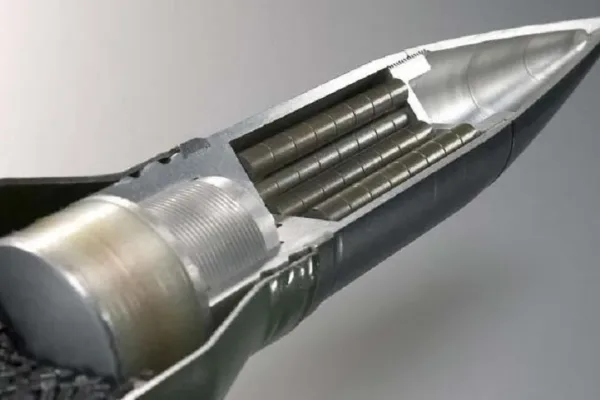

At MetalsTek Engineering, we specialize in producing custom Tungsten Nickel Copper (WNiCu) alloy parts tailored to various industries’ specific needs. WNiCu alloys are ideal for applications requiring durability and precision because of their exceptional strength, high density, and excellent machinability.

Material: Tungsten Nickel Copper Alloy, W-Ni-Cu

Composition: W 85~99%, Can be Customized

Density: 16.8-18.75 g/cm3

Size Range: Tailored Shape and Size per Drawing

Application: Military Industry, Counterweight, Radiation Shielding, Dart Rod, Welding Rod, Mold

WNiCu alloy is a composite material made primarily of tungsten (W), nickel (Ni), and copper (Cu). This unique combination provides several advantages:

At MetalsTek Engineering, we offer extensive customization options for WNiCu alloy parts:

Choosing MetalsTek Engineering for your custom WNiCu alloy parts means you benefit from:

ASTM B777 (MIL-T-21014 / SAE-AMS-T-21014) is a standard specification for Tungsten Heavy Alloys (WHA). The specification is organized into four classes (1-4). Each categorization or classification represents a percentage amount of Tungsten (W) Alloy.

Class 1: W 90%

Class 2: W 92.5%

Class 3: W 95%

Class 4: W 97.5%

| Tungsten Heavy Alloy Grade | WHA-17C | WHA-17F | WHA-175 | WHA-18C | WHA-18F | WHA-185 |

| ASTM B777; AMS-T-21014 Class | Class 1 | Class 2 | Class 3 | Class 4 | ||

| Type | Type II & III | Type II & III | Type II & III | Type II & III | Type II & III | Type II & III |

| AMS 7725C | Type 1 | Type 2 | ||||

| Alloy Composition | 90WNiCu | 90WNiFe | 92.5WNiFe | 95WNiCu | 95WNiFe | 97WNiFe |

| 90% W | 90% W | 92.5% W | 95% W | 95% W | 97% W | |

| 6% Ni | 7% Ni | 5.25% Ni | 3.5% Ni | 3.5% Ni | 2.1% Ni | |

| 4% Cu | 3% Fe | 2.25% Fe | 1.5% Cu | 1.5% Fe | 0.9% Fe | |

| Density (g/cm3) | 17 | 17 | 17.5 | 18 | 18 | 18.5 |

| Density (lbs/in3) | 0.614 | 0.614 | 0.632 | 0.65 | 0.65 | 0.668 |

| Hardness (HRC) | 24~32 | 25~32 | 26~32 | 27~34 | 27~34 | 28~35 |

| Tensile Strength (PSI) | ≥94,000 | ≥110,000 | ≥110,000 | ≥94,000 | ≥105,000 | ≥100,000 |

| Yield Strength (PSI) 2% OFFSET | ≥75,000 | |||||

| Elongation, % in 1” | >2 | >5 | >5 | >2 | >3 | >2 |

| Proportional Elastic Limit (PSI) | 45,000 | 52,000 | 46,000 | 45,000 | 44,000 | 45,000 |

| Modulus of Elasticity (PSI) | 40 x 106 | 45 x 106 | 47 x 106 | 45 x 106 | 50 x 106 | 53 x 106 |

| Coefficient of Thermal Expansion x 10E-6/°C (20°- 400°C) | 5.4 | 4.8 | 4.6 | 4.4 | 4.6 | 4.5 |

| Thermal Conductivity (cal/s*cm*K) | 0.23 | 0.18 | 0.2 | 0.33 | 0.26 | 0.3 |

| Electrical Conductivity (%IACS) | 14 | 10 | 13 | 16 | 13 | 17 |

| Magnetic Properties | NIL | Slightly Magnetic | Slightly Magnetic | NIL | Slightly Magnetic | Slightly Magnetic |

There are many different ways to use Tungsten heavy alloy (WHA). Mostly, we provide WHA parts for ballast weights, radiation shields, boring bars, ordnance components, and other things that need to be really heavy and flexible.

WHA is commonly used in various applications, such as counterweights, inertial masses, radiation shielding, and ordnance products. It is preferred for its strength, density, and weight, making it suitable for applications that require balance weights, such as turbines, crankshafts, and helicopter rotors.

WHA is also used in commercial and military aircraft, spacecraft, defense vehicles, transportation systems, warheads, munitions, and fragmentation.

In the medical industry, WHAs are used for X-ray shielding in applications such as CT and imaging technologies, nuclear medicine shielding, and surgical robots. The alloying of tungsten allows for the production of complex shapes and forms needed for critical medical devices and technologies.

Below are the typical uses of WNiCu WHA:

Our Tungsten Heavy Alloy products are meticulously tagged and externally labeled, ensuring both efficient identification and rigorous quality control. We prioritize utmost care to prevent any potential damage that may occur during storage or transportation.